Showcasing the capabilities of the system and enabling the company to better inform potential purchasers about operational parameters and enhance downstream customer support.

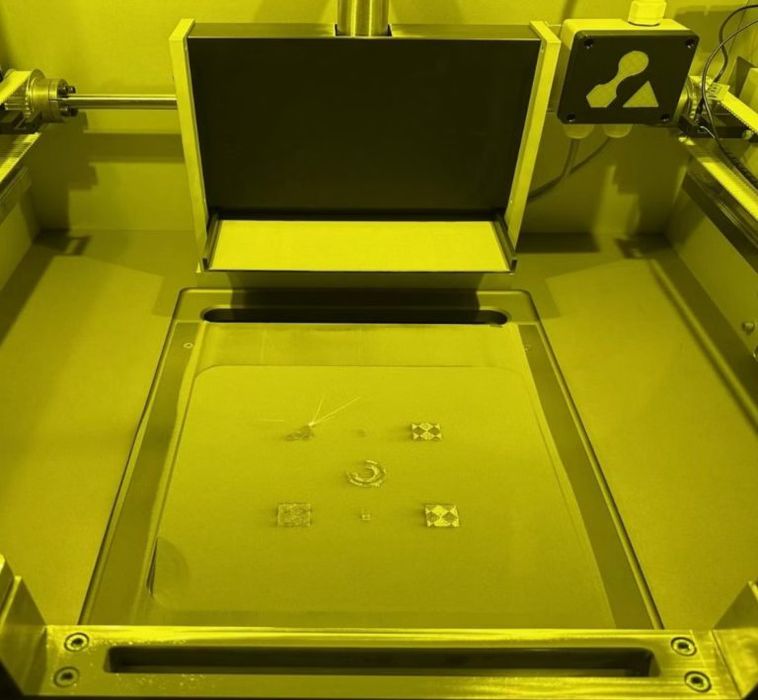

Aurora Labs Limited (A3D), an Australian 3D printer manufacturer, has started printing with the AL250 metal 3D printer – designed, engineered, and built in Australia – at its industrial printing services facility, in Perth.

Parts printed in Inconel 625 have been processed for the development of a new production printing parameter window – tuned to the AL250. This widely used nickel-based, super alloy is found in aerospace and many industrial applications including oil and gas components or aerospace rocketry, due to its excellent thermal, corrosion resistance, and fatigue properties. The data achieved for the Inconel 625 properties includes hardness as built 315 HV10 and part density at 8.4g/cm³.

The team will soon be printing full-scale micro gas turbines in this alloy and developing further print applications to expand its product offerings in the area of micro gas turbines and related parts.

The launch of the first commercial AL250 machine will serve a dual purpose as a demonstrator unit within the company’s 3D printing services facility. This strategy allows Aurora Labs to showcase the full potential of its printing technology. By doing so, the company can better inform potential purchasers about operational parameters, enhance downstream customer support, and ensure a reliable, high-performing product that meets their needs.

“The AL250 3D printer is a significant advancement for our industrial printing service and machine-building capabilities. It will meet the increasing demand for specialized materials as we expand our capabilities and scale up production for the Defence industry, reinforcing our commitment to developing machines tailored for practical industrial printing applications. The AL250 is equipped with multiple commercial features, ensuring a user-friendly and seamless experience. Its compact, easy-to-clean build chamber supports a generous 250 x 250 x 300mm 3D print area. This machine excels at printing intricate, mid-sized geometries, making it a valuable addition to our expanding print service,” said Rebekah Letheby, CEO of Aurora Labs.

Read the rest of this story at VoxelMatters