Assembrix offers a unique way to participate in a manufacturing network.

Manufacturing networks are a growing concept with several large players on the market. The idea is to provide a central point and infrastructure for manufacturers to access excess machine capacity at other factories. A buyer can use the network to route their 3D print job to an appropriate provider, who then produces the parts. The network looks after payments, and takes a small cut of transactions.

That model has worked pretty well for several large players, including Protolabs and Xometry. However, a new player on the scene is Assembrix from Germany.

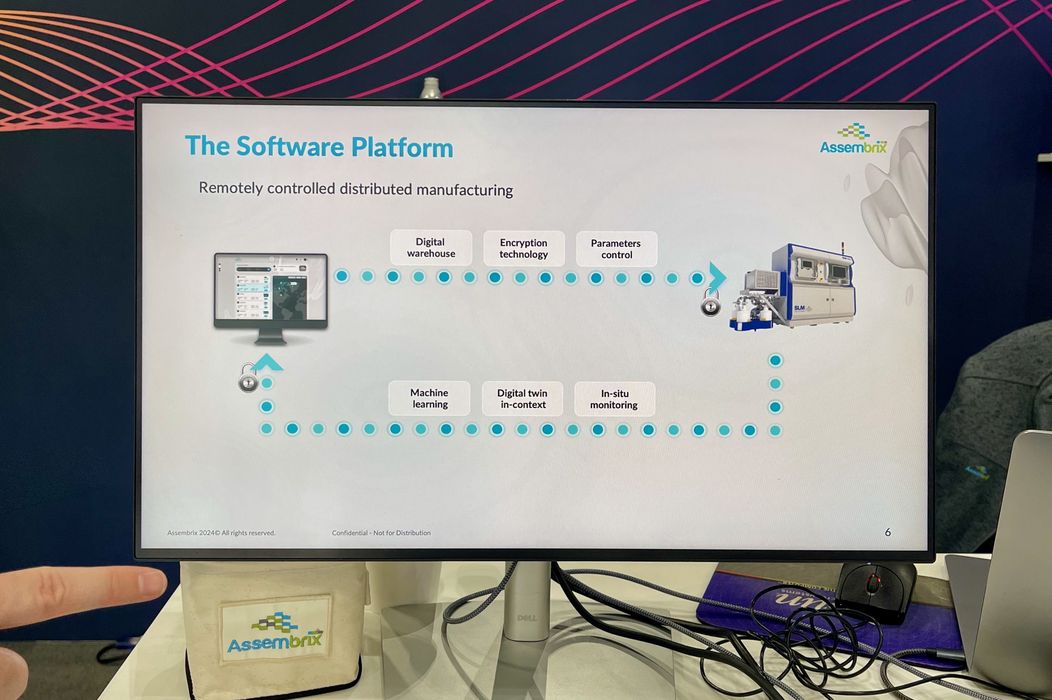

At a high level, the concept is the same: suppliers provide machine capacity for manufacturers seeking parts, and Assembrix manages the process with their cloud-based system. However, there’s quite a few differences in how it’s done.

Assembrix talks about a “Virtual Manufacturing Space”, and that’s basically what they create. A manufacturer is “extended” into the virtual capacity provided by the supplier. This is done through a direct, real time connection to the equipment.

Hold on, isn’t that a security risk? Not with Assembrix, as their system uses a completely secure end-to-end link between software and machine, using “advanced blockchain-based encryption technology”. Why do this? Assembrix explains:

“The cloud-based platform also includes in-situ monitoring, providing manufacturers real-time access to data of the entire process for quality and cost control purposes.”

That’s not all that’s happening. They’re using machine learning and digital twin technology to ensure quality is achieved through continuous monitoring of data points during printing.

Assembrix said this allows an OEM to outsource any manufacturing task while maintaining full control over the process. That’s quite different from many manufacturing networks where 3D files are haphazardly sent to and fro.

For the supplier, Assembrix provides comprehensive dashboards to manage the process. Whereas a manufacturer sees their virtual manufacturing space, a supplier sees their equipment and is able to allocate out unused periods for virtual use.

Currently they have apparently hundreds of partners located worldwide in a variety of industries. This means that Assembrix clients can easily leverage the spare capacity of all these organizations to get their parts produced quickly.

How is this all achieved? It seems that Assembrix has been developing direct integrations with a number of 3D printer manufacturers. This allows for the transfer of the required data during printing.

Their list of integration partners includes Nikon SLM, EOS and others. I suspect they will be adding more as their network grows.

Via Assembrix