There’s a controversy emerging over the true strength of carbon fiber-reinforced filaments.

Carbon fiber filaments are now widely available from many sources. These filaments are essentially standard polymers like nylon, PETG, or PLA mixed with tiny segments of chopped carbon fiber. The segments are very short to allow them to flow freely through the tiny nozzles of FFF devices.

Carbon fiber is an extremely strong material, so the idea is to strengthen the parts by adding it to the polymer. This is similar to adding gravel to cement to create concrete.

Anyone who has printed a “CF” part will attest to the apparent strength: the parts are far more rigid. Because of that property, CF parts are increasingly used in mechanical applications.

But how strong are these parts? Swiss YouTube channel “I Built a Thing” decided to do some testing, and the results are very surprising.

The theory investigated is that the presence of the carbon fiber segments actually reduces the tensile strength of the parts, rather than increasing it.

It all comes down to how the carbon fiber segments act near the layer boundaries of a FFF 3D print:

- If the CF segments are not near the layer, then the layer strength is simply the polymer molecules bonding to each other, the same strength as the non-CF polymer.

- If the CF segments are laid directly along the layer boundary by chance, then they do not provide any layer adhesion: CF does not bond with polymers.

- No CF segments pass through both layers because the layers are deposited separately.

If you think about this, there is no way for CF to increase the tensile strength of a part in the Z-axis. It should only decrease it because of the inability of CF to bond with polymers.

On the other axes, we should see an increase in tensile strength because the CF segments are randomly oriented and act like “gravel”.

Was this the case? “I Built a Thing” did an extensive test of PETG-CF and PLA-CF, and checked the resulting parts using precision measurement equipment. Parts were tested in all axes to determine any differences in tensile strength.

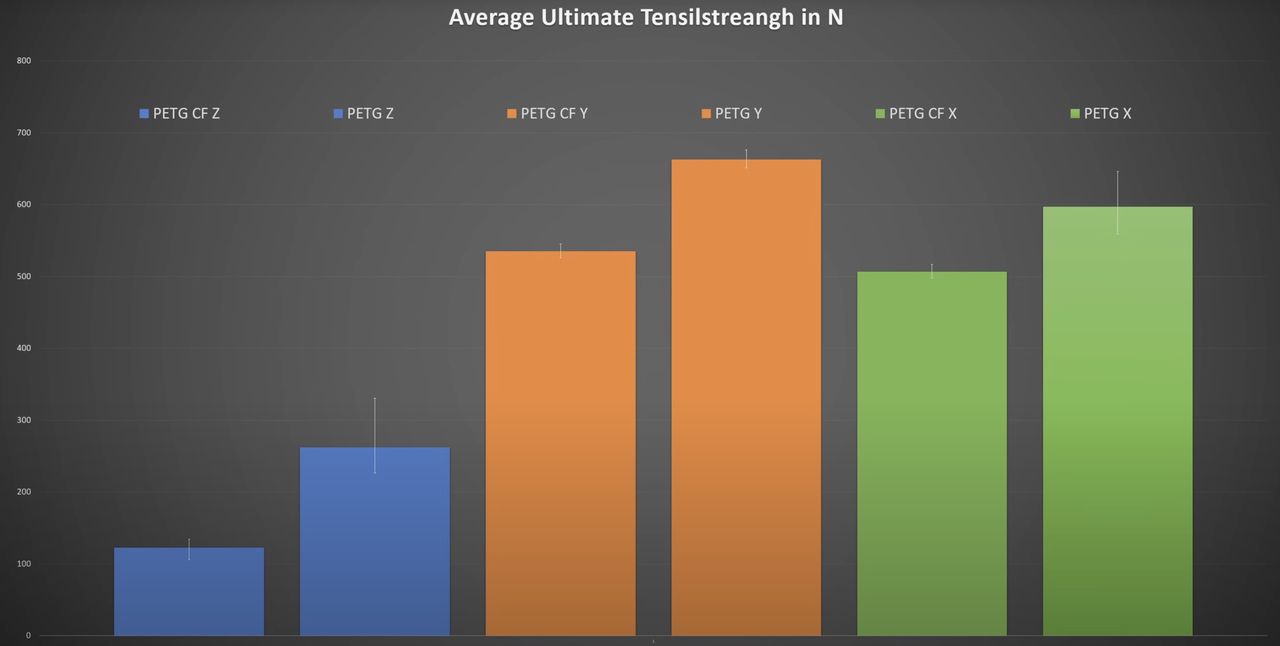

The results are quite interesting. Here we see a comparison of PETG and PETG-CF with all axes. Note that in each case, the CF version is substantially weaker in tensile strength.

While this makes intuitive sense for the Z-axis as explained above, it also seems to be the case for both X and Y axes!

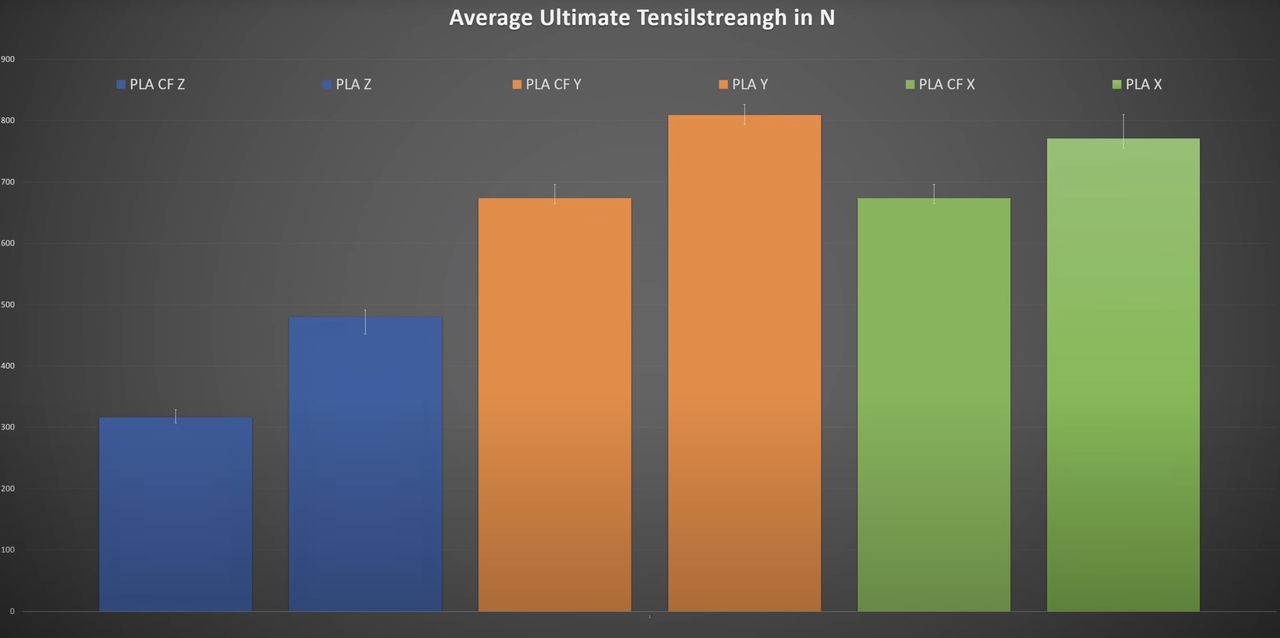

Does this effect hold on PLA-CF material? It turns out to be similar results:

Note that the drop in strength on PLA isn’t quite as much as with PETG, likely due to differences in the polymer bonding ability of PLA and PETG.

What does all this mean?

If your application relies on tensile strength, then CF filaments are probably not as good a choice as you thought. We don’t know about other mechanical properties, as this test only focused on tensile strength.

This also exposes the unreliability of CF product marketing. Inevitably, these materials are touted as being “strong”, but are they really? It may be that certain properties are actually stronger, but in at least the case of tensile strength, they are not, according to these test results.

You may want to reconsider the use of CF materials in some situations, particularly because they are usually far more expensive than plain filaments.

It sounds like this investigation is going to turn into an official research paper, but it has not been published yet.

The message here is that parts made from CF filaments may not be as strong as you may have thought.

Via YouTube