AM-Flow is quietly building up an impressive portfolio of automation functions for additive manufacturing.

Every time I meet with the company I see additional features being added to their now comprehensive post processing options.

The problem they are solving is the issue of how to handle streams of customized (i.e. non-identical) parts flowing out of factory 3D printers. We all want the tech to be used in manufacturing, where plenty of parts will be made, but what do you do with them once made?

The post processing speed must match the print speed, otherwise there’s no point.

AM-Flow’s portfolio of products is now quite extensive:

- AM-VISION

- AM-LOGIC

- AM-SORT

- AM-BAGGING

- AM-PICK

- AM-ID

- AM-ROUTE

- AM-EXPERT

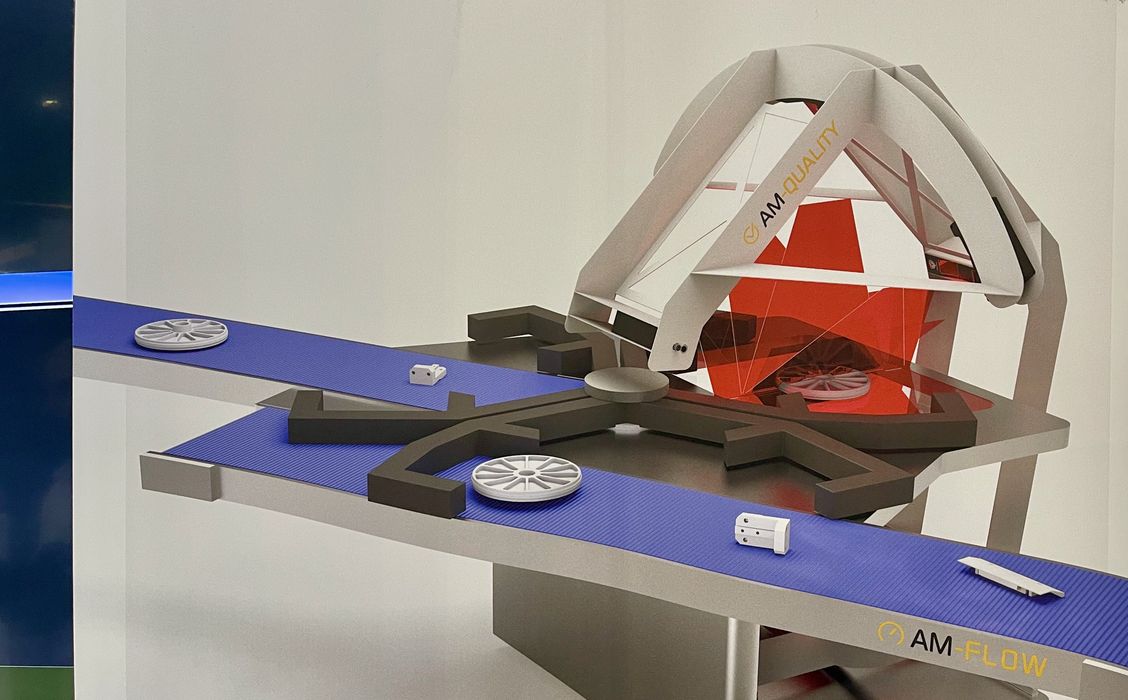

- AM-QUALITY

These could be considered building blocks, where the buyer determines the configuration necessary to handle the flow of 3D printed parts coming off their systems. Depending on what’s needed, different configurations of AM-Flow components would be organized. Some operations might need bagging, but others not, for example.

In speaking with AM-Flow representatives, they tell me they are seeing a more emphasis on quality from their customers. This becomes quite complex as part production volumes increase, as manual solutions don’t scale.

AM-Flow has the ability to configure an automated solution that will handle quality. As an example, a part will be collected into an AM-Flow system and whisked into the AM-VISION system. There the part is scanned in under five seconds. I’m told their vision system now includes eight cameras, inclusion some down low to scan the bottom of the object.

The scan is then used to identify the part in a database of parts. That 3D model is retrieved and immediately compared with the scan results to see if the part is within dimensional tolerances.

At top you can see the AM-Flow tablet interface, which would be used by the post processing operator. The part in question has been tagged as “failed”, apparently because it didn’t meet dimensional specifications. This allows the operator to immediately take the part out of the flow. It’s a simple “ok or not ok” approach that takes away the need for highly trained operators.

In addition, the software can produce a report for this particular part. That’s quite interesting: the system can make individual reports on every part flowing through their system.

AM-Flow is well-positioned for the future. As we see new, high throughput 3D print tech make its way into the manufacturing world, those manufacturers will surely require equally high throughput post processing capabilities.

The one constraint I can see here is that AM-Flows’ system is capable of handling moderately sized prints. Meanwhile the big push into manufacturing is mostly taking place with large and heavy metal parts. It may be that AM-Flow could develop a heftier system in the future to handle larger parts.

Via AM-Flow