Aerosint has made some improvements to their unique multimaterial powder 3D printing technology.

The company made big news some years ago when the released the industry’s first multimaterial powder 3D printer using their Selective Powder Deposition (SPD) tech. Before then all LPBF machines would allow only a single powder material in the build chamber.

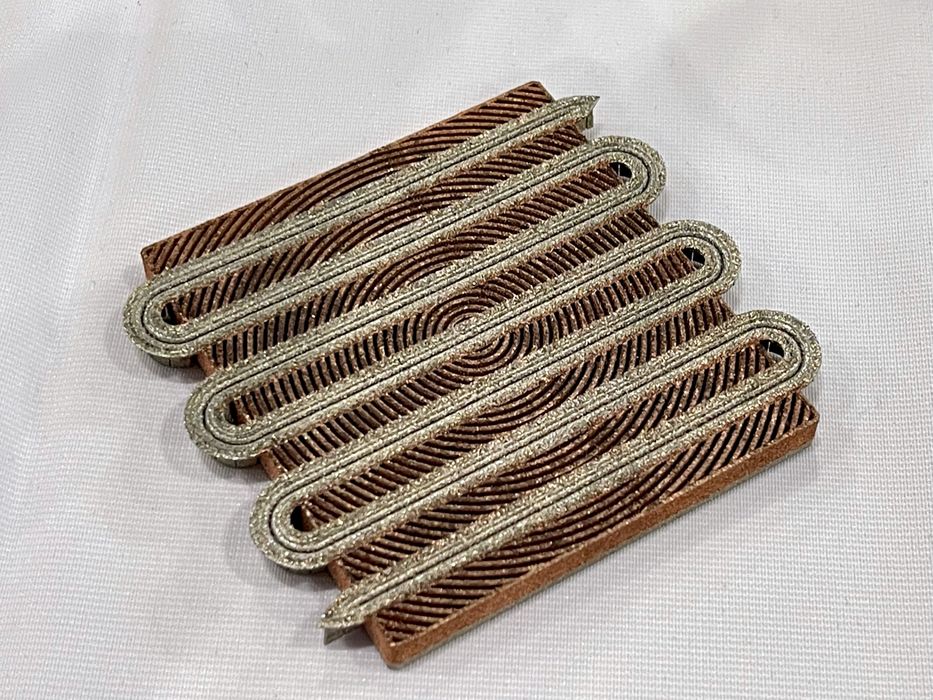

Aerosint developed a system in which powder could be selectively dropped during the recoating process between layers. This allowed their system to deposit different materials at desired locations, making multimaterial powder prints possible for the first time.

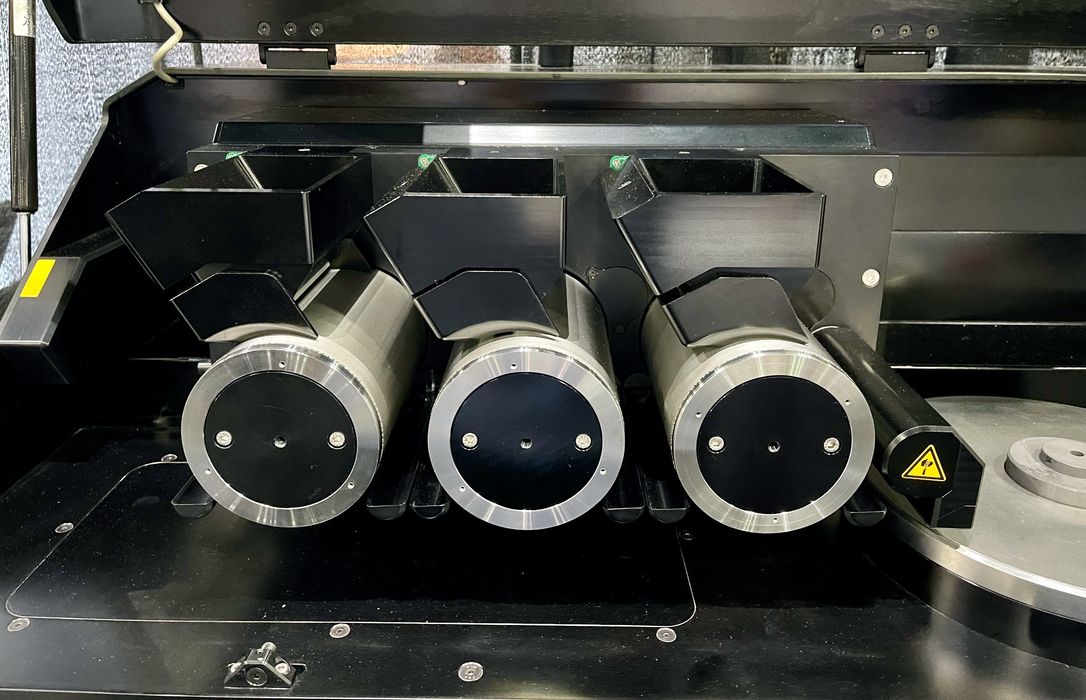

Their initial systems involved two different powders, but now they’ve moved to three. All Aerosint systems now include three material capability.

The move to three materials offers the possibility of printing three materials, obviously, but there is another benefit that had not occurred to me: powder recycling.

In typical LPBF systems the unfused powder usually gets recycled due to the high powder cost. The loose powder is collected after print jobs complete and sent through sieves to trap any stray bits. Some ratio of fresh powder and recycled powder can be used on subsequent jobs.

But with a multimaterial powder system, how do you recycle loose powder that’s made from two (or more) different materials? The mixed powder can’t really be sorted out, so is it all waste?

Aerosint provided an interesting answer, and it all has to do with the addition of the third material. In a post they explain:

“Rather than trying to recycle mixed powders, our preferred strategy to solve this problem is to avoid material waste in the first place. This is accomplished by adding a third material to the process that we call the “filler material”.

The filler material, as compared to the two “functional materials”, will not be fused or incorporated into the part. The filler material is deposited to literally “fill” the powder bed with powder.

At the end of the printing process, all the filler material is recovered and re-used in the next build job preventing any kind of waste. Even if the filler material gets contaminated by a bit of non-fused functional metal powder, this will not be an issue because the filler material will only be reused as filler material. A filler material is never reused as a functional material.“

They’ve also improved their recoating system to improve print quality. The layers can now be as small as 0.300mm, whereas previously they were 0.500mm, according to the Aerosint representative we spoke with.

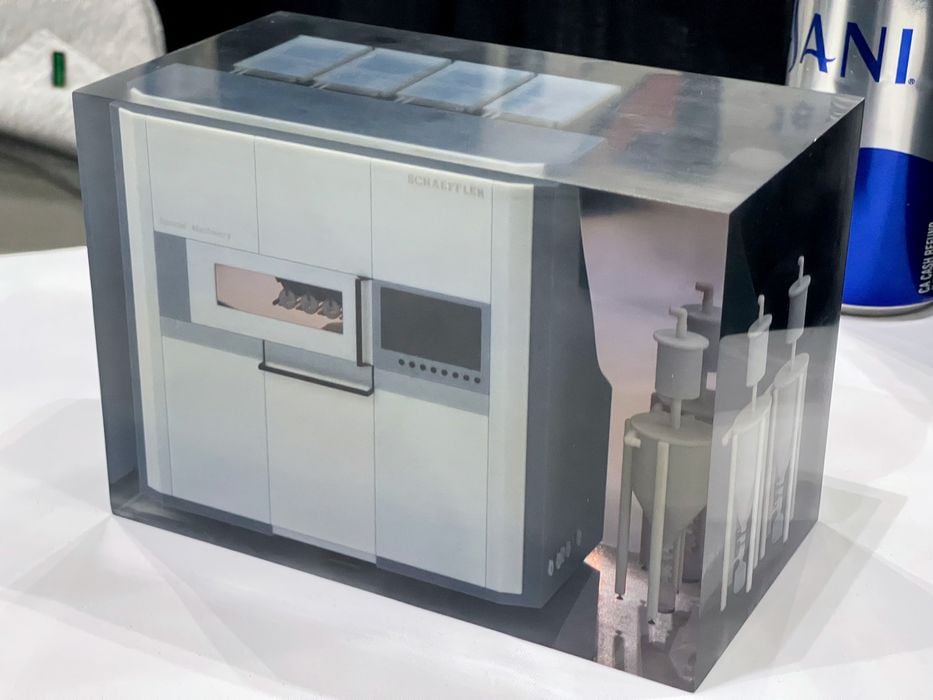

Their technology is capable of being used with metal, ceramic and polymer powders, and has been implemented on the AconityMIDI+ industrial 3D printer as an option. Aerosint can also integrate SPD technology into other machines.

We were told the company is working on an “Omni” product to be released later this year. The new machine is said to be larger and could possibly use up to four lasers for increased throughput.

One more thing about Aerosint. The company was acquired by Desktop Metal a few years ago, but now Desktop Metal is in the process of being acquired by Nano Dimension. This means that in the near future it’s likely that Aerosint technology could appear in Nano Dimension equipment.

Via Aerosint