A new research paper explores the idea of personalized 3D printed drugs.

The concept is quite fascinating: imagine a device, perhaps in a pharmacy, that is able to produce pills that are the precise type and dose for your prescription.

Tt’s more than just that. Imagine further that these 3D printed pills might vary the dose by day, perhaps even following a custom “profile” of dosage requirements for a treatment period.

But wait, there’s more: imagine even further that these 3D printed pills might include drugs for not only one treatment, but several. In this way the patient could take one (or at least fewer) pills and still receive all the benefits of treatment.

That’s the dream, but it’s incredibly hard to do.

Aside from the ubiquitous regulatory environment for pill delivery, there are quite a few technical issues.

One is that 3D printing of pills must be done in a complete food safe, biocompatible manner. That’s something that is known, but must be part of the printed pill solution.

Another issue is that the drugs make up only a portion of the actual pill. The remainder of the pill is composed of fillers that “carry” the drugs to the patient. The problem is that the list of materials that are 3D printable is quite short, and this places a number of constraints on pill design.

Pills aren’t simply the intended drugs. Many pills deliver drugs that must be released in a metered manner over a time period. To accomplish this pills typically have a coating that slowly dissolves, gradually releasing the desired drugs in the required time.

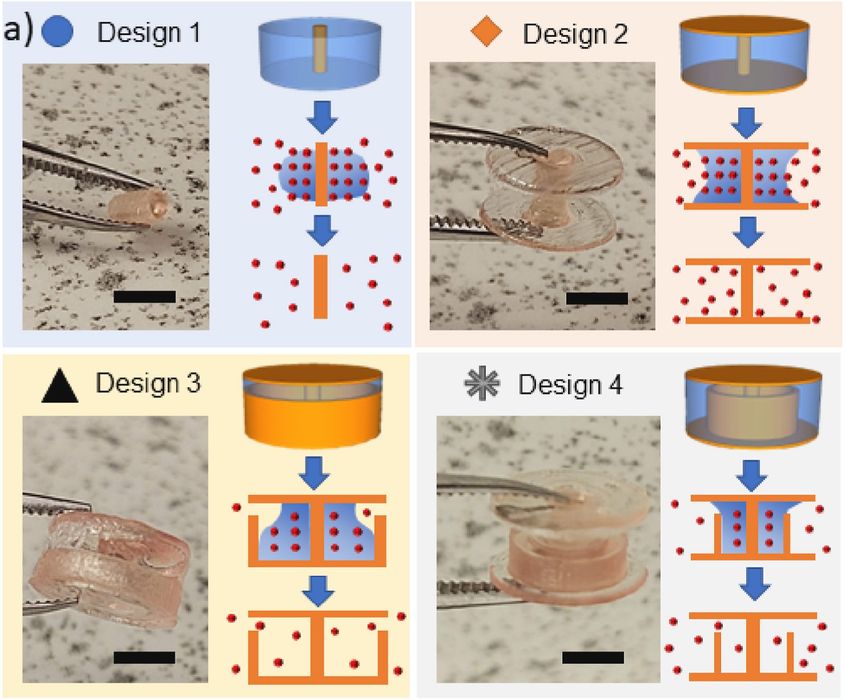

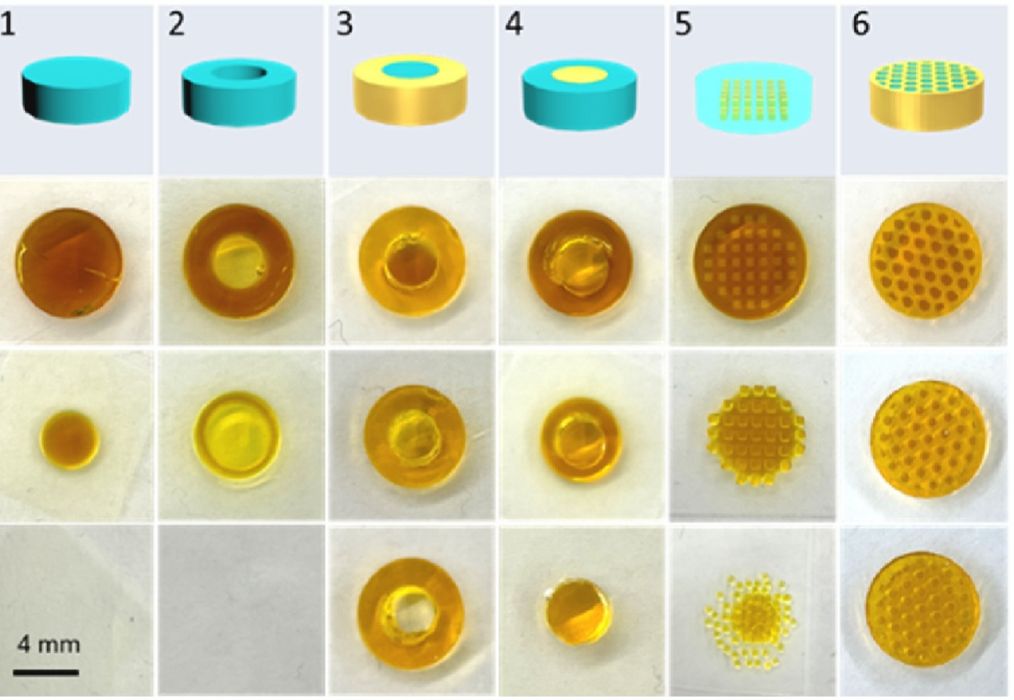

3D printed pills must replicate this effect, and if so, could offer many additional possibilities for metered drug release through the use of more complex dissolvable structures.

The new research attempts to develop approaches to overcome these and other challenges. They explain:

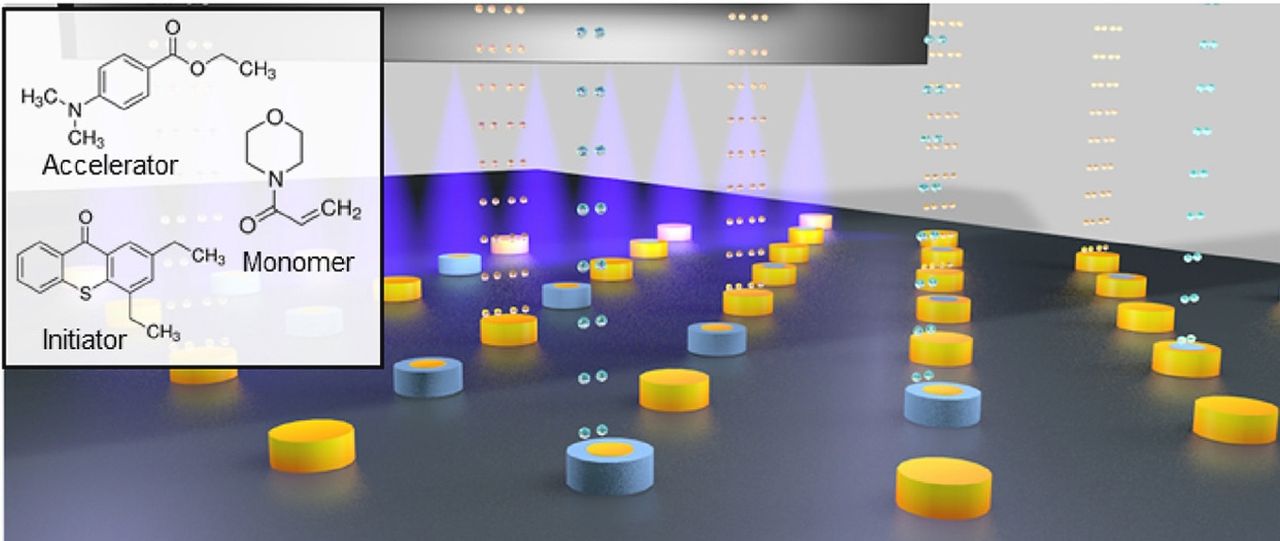

“We propose that MM-IJ3DP, as a scalable AM process, can offer unprecedented opportunities for accessing personalised drug delivery compositions, and consequently drug release profiles, that are not feasible with conventional manufacturing methods, such as granulation, or direct compression. Therefore, we explored the possibility of manufacturing complex multi-material structures, exemplifying the range of designs available via inkjet based 3D printing, and manufacture multi-material structures with controlled release of a model drug. We exploited a pill design that changes the exposed soluble excipient surface to volume ratio over time to control drug release. MM-IJ3DP was used to produce a range of designs containing insoluble and soluble polymers, in a single manufacturing step.”

Their design was indeed able to meet normal programmable release rates, thus enabling the use of this technology in a more practical manner.

We’re a very long way from this breakthrough to a world where 3D printed drugs are available to the public, but every long journey requires many steps. This is one of them.

Via Science Direct