Additive Industries announced a new partnership that follows an emerging trend in metal 3D printing.

The company produces advanced metal 3D printers for industry, including their latest device, the MetalFab 300 Flex, the first metal 3D printer with an adjustable build volume. The company was one of the first to recognize the typical manufacturing workflow and integrate those needs into their machine designs.

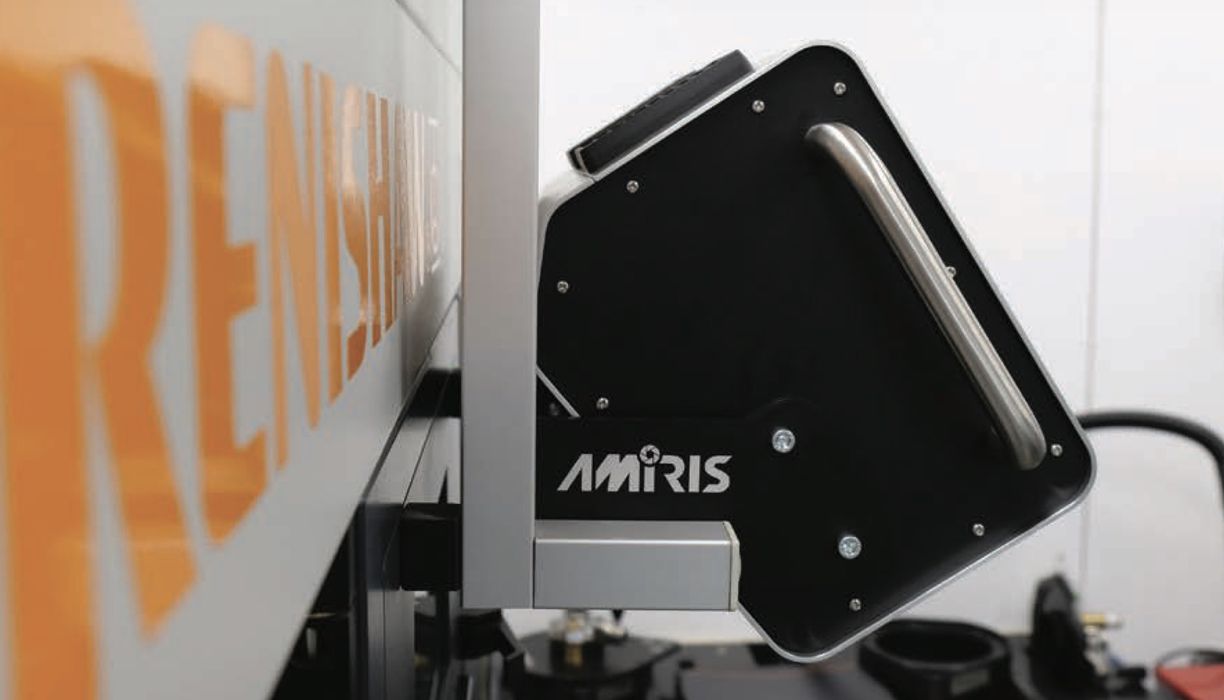

They’ve now partnered with Additive Assurance, an Australian company providing an independent sensor system, AMiRIS, for real-time monitoring of print quality in metal LPBF 3D printers. It involves attaching a device to the 3D printer, which performs the data collection. This is then analyzed by software, which provides a number of useful functions, including:

- Alerts when something goes sideways

- Production KPI dashboard

- Single platform for quality assurance metrics

- Micron-level process monitoring

The system uses machine learning and is capable of integrating on almost any metal 3D printer. Amazingly, it installs in only 30 minutes and doesn’t disrupt the printer at all: warranties are not broken.

Why partner with Additive Assurance? Additive Industries CEO Mark Massey explained:

“Our partnership with Additive Assurance aligns perfectly with our commitment to advancing the capabilities of metal additive manufacturing. By integrating AMiRIS® with our MetalFab portfolio, including our new MetalFab 300 Flex, we’re enhancing real-time quality assurance, offering our customers greater flexibility, and setting new standards in production consistency and reliability.”

This is what it’s all about: quality assurance.

3D printing emerged initially into prototyping applications, mainly due to the poor quality of parts and extremely constrained set of possible materials. Prototyping proved quite successful, but prototypes are not production parts: they don’t require the same levels of consistency and quality.

Later on, metal 3D printers emerged, having the ability to produce parts in metal that were entirely usable for production purposes. However, coming from the prototyping background, many metal 3D printers had few quality assurance features: they weren’t required for prototyping.

Since then it’s become clear that quality and consistency has far greater importance. As such we now find many metal 3D printer manufacturers focusing on these aspects, either internally or through partnerships, including this one between Additive Industries and Additive Assurance.

Today if you are 3D printing metal parts for production, quality assurance is mandatory.