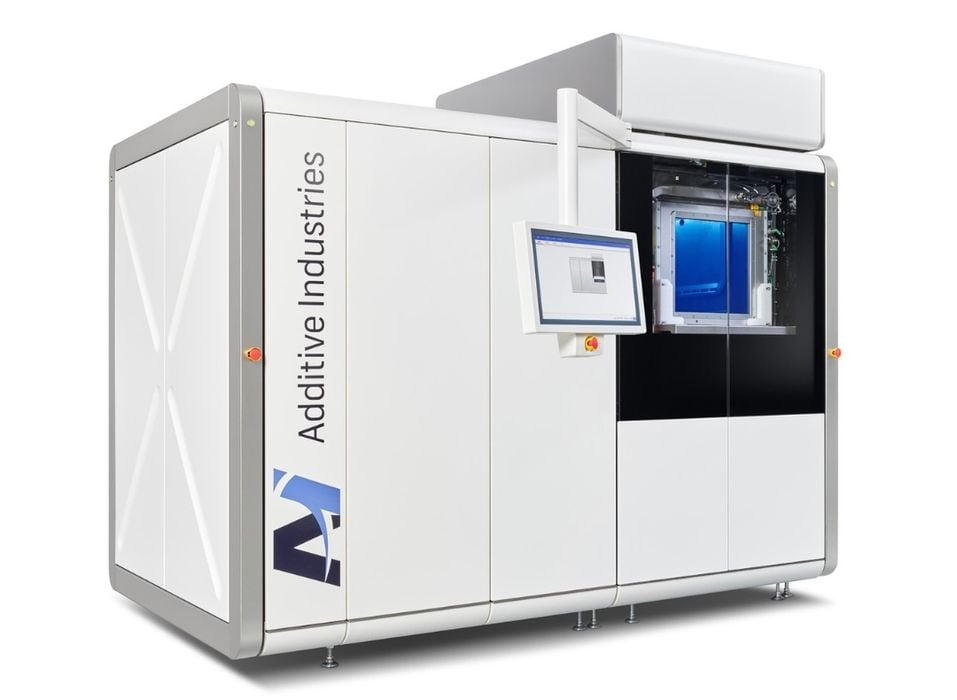

Additive Industries has a new 3D printer.

The new device is the MetalFab 300 Flex, and it is somewhat similar to the company’s prior LBPF metal devices, but also very different.

As you might guess from the product’s name, it sports a build volume of 300 x 300 x 400 mm, which is quite reasonable for many industrial parts. However, the remainder of the product’s name gives away the true secret feature: Flex.

The Flex has a flexible build volume, and that’s something we have not seen previously with an LBPF device. We have had custom 3D printers previously from other providers, where the customer specifies a build volume and that’s how it’s built. But such machines cannot (easily) change size after they are produced.

That’s what’s different about the MetalFab 300 Flex: it CAN change its build volume after the fact.

Additive Industries explains:

“This latest configuration of metal printer offers a unique on-demand platform size, providing unprecedented flexibility for manufacturers, making metal AM more accessible than ever and the first of its kind in the industry.”

How exactly would this work? It turns out that the machine’s actual build volume is a much larger 420 x 420 x 400 mm, but the base level of the device permits use to a smaller 300 x 300 x 400 mm. It seems that the build volume is software controlled.

Additive Industries has priced the expanded build volume by subscription. Customers can select to “expand by software” their build volume on either an annual or monthly subscription.

In other words, the MetalFab 300 Flex flexes up AND down in build volume.

There are a couple of scenarios where this could be quite useful.

One scenario would be a company that doesn’t have the cash to get a larger machine, but opts for a smaller machine. As they build up revenue and business, they can activate the larger build volume to produce more throughput. That’s quite advantageous over buying an entirely new machine, and leverages all existing processes, software, materials and floorspace.

Another scenario would be in a service that suddenly gains a one-time order for big parts that don’t fit in the machine. That organization could then choose to subscribe for the larger build volume for a short period, perhaps a month or two, in order to complete the bigger order.

That’s quite a bit of flexibility. The latter scenario is interesting in that the organization would have otherwise been faced with buying a bigger machine at far higher expense, or losing the customer. The MetalFab 300 Flex solves that problem.

Aside from the flexible build volume, the MetalFab 300 Flex includes dual 500W lasers, each of which can cover the entire build surface. That should make it possible to produce prints faster than when using only a single laser.

The MetalFab 300 Flex seems like an intriguing option for certain companies. If the concept sticks, then perhaps we may see Additive Industries develop alternative configurations that offer even more — or less — build volume. We may also see competing metal 3D printers create similar flexible platforms.