Some lesser-known 3D printing simulation software with examples of implementation.

Simulation is an essential tool in additive manufacturing (AM), with numerous options available from the largest engineering software companies. Of course, advanced engineering software doesn’t come cheap and it’s not always easy to persuade management to shell out for yet another tool, no matter how essential it may seem.

That’s why we created this list of seven free simulation tools that may have flown under your radar, but which are nevertheless worth considering, especially if you’re having difficulty loosening the corporate purse strings.

Elmer FEM

Elmer is a free and open-source software developed in Finland that includes models for fluid dynamics, structural mechanics, electromagnetics, heat transfer and acoustics. These multiphysics problems are described by partial differential equations (PDE) and solved using the Finite Element Method (FEM). In addition to the numerical solver that is the core of this software, Elmer has additional modules for mesh conversion, post-processing and a graphical user interface. It runs on Windows, Linux and macOS and the solver can also be used in a multi-host parallel mode on platforms that support the Message Passing Interface (MPI).

In the context of 3D printing, engineers at Chemnitz University of Technology in Germany used Elmer to simulate a single seam Wire Arc Additive Manufacturing (WAAM) process on a stainless steel base plate with stainless steel welding wire. They found that Elmer generated high-quality results which accurately represented the temperature development in their experimental process.

FreeFEM

FreeFEM (sometimes referred to as FreeFEM++) is a free programming language and software designed for solving 2D and 3D PDE using FEM. Its pre-built physics include incompressible Navier-Stokes equations, Lamé equations, thermal diffusion, convection and radiation; and fluid-structure interaction (FSI). The software is written in C++ and was developed by what used to be called Pierre and Marie Curie University in France, before that institution merged into Sorbonne University. One of the oldest items on this list, the first version of FreeFEM was created in 1987 exclusively for Macintosh.

Engineers at Ecole Polytechnique in France used FreeFEM as part of their research into topology optimization for 3D printed supports that are imperfectly bonded for easier removal. In this context, FreeFEM was used for finite element analysis to demonstrate that different support designs are needed depending on whether the support/part interface is perfect or imperfect.

GEKKO

GEKKO Optimization Suite is a free Python package for machine learning and optimization of mixed-integer and differential algebraic equations coupled with nonlinear programming solvers. It can be used for parameter regression, data reconciliation, real-time optimization, dynamic simulation and nonlinear predictive control. GEKKO works on Windows, Linux and macOS as an extension of the Advanced Process Monitor (APM) Optimization Suite, with the addition of integrated modeling and solution visualization.

GEKKO has been deployed in a variety of applications, including cogeneration, drilling automation, solid oxide fuel cells and unmanned aerial vehicles (UAVs), but it also has uses in additive manufacturing. For example, an engineering master’s student at Ohio State University used it to simulate cyclic scheduling for post-production heat treatments of AM parts made from a titanium alloy to remove residual stress.

NetLogo

NetLogo is a free and open-source programming language and integrated development environment (IDE) designed at Northwestern University. It was built to be easily accessible as well as powerful, making it suitable for teaching children and for experts who lack a programming background. To that end, the environment comes with models from a variety of domains, including economics, biology and psychology as well as physics, chemistry and system dynamics. Along with agent-based modeling, NetLogo’s IDE also includes basic support for dynamic system modeling.

NetLogo has been applied to additive manufacturing in several ways, including creating an agent-based model to support responsible AM research and innovation, using agent-based modeling to simulate osseointegration of titanium implants and modeling the supply chain impacts of AM in the healthcare industry.

Project Chrono

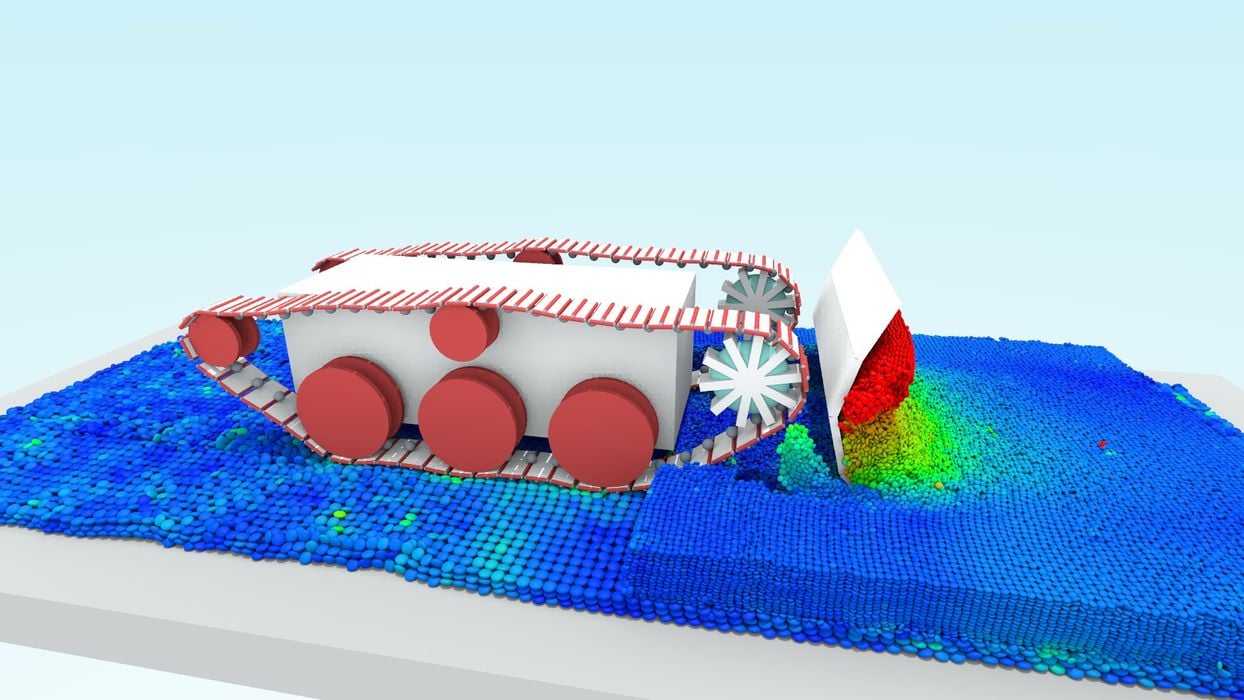

Project Chrono is a free and open-source multibody physics simulation tool developed by the University of Parma and the University of Wisconsin-Madison. It can simulate both rigid and soft body dynamics, as well as collision detection, fluid-solid interaction, granular dynamics and other physical systems. Originally designed as a simulation tool for robotics and biomechanics applications, the software has expanded considerably since then, thanks in part to a $1.8M investment from the U.S. Army, which uses it to simulate wheeled and tracked vehicles.

In the context of additive manufacturing, the Chrono engine has been used by engineers at the University of Wisconsin-Madison to model layering in selective laser sintering (SLS) for complex structures as well as optimizing build volumes and gauging the effects of granular mixture parameters on surface finish.

Scilab

Scilab is a free and open-source numerical computational package and high-level, numerically oriented programming language that should seem familiar to anyone acquainted with MATLAB or Simulink. The software has applications in signal processing, statistical analysis, fluid dynamics and the simulation of explicit and implicit dynamical systems, though this last capability requires an additional free package called Xcos.

The software has been used to evaluate the viability of a high-entropy alloy in selective laser melting (SLM), to simulate screw-based extrusion of PEEK, to solve kinematic problems of robotic arm manipulators for fused filament fabrication (FFF) and, most recently, to elaborate and implement trajectory planning and machine code generation for WAAM.

Read the rest of this story at ENGINEERING.com