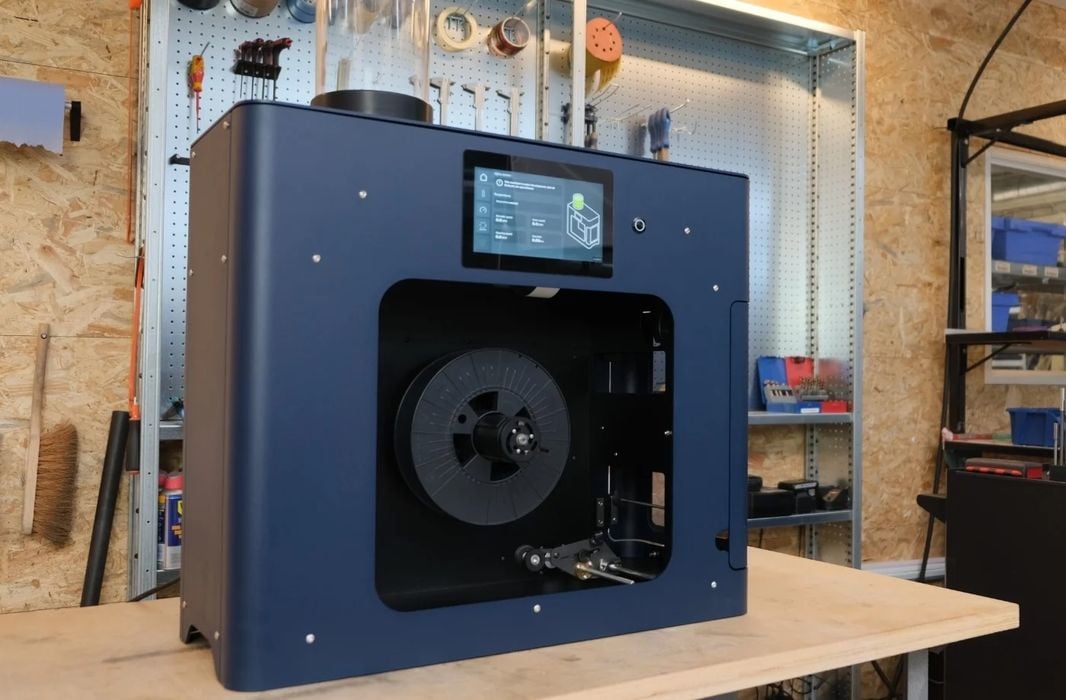

3DEVO announced a significant upgrade to their filament production lineup, introducing the Filament Maker TWO.

Succeeding the Filament Maker ONE, the new device promises increased filament quality and a number of new features.

3DEVO is perhaps the only company that’s figured out how to properly perform desktop filament production. While the notion of grinding up pellets and extruding them seems pretty straightforward, it’s really not that at all.

Filament production requires extremely precise control over speeds and temperatures in order to produce high-quality filament. Casual setups making filament typically produce unusable filament, particularly in today’s high-speed 3D printers that require high-quality input filament to get high-quality output parts.

What’s changed in the Filament Maker TWO? There seem to be two major changes.

One of them is a much longer drive screw. This is the “auger” that pulls in pellets into the heating chamber and pushes out the filament. 3DEVO explains three advantages of this design:

- A more optimal L/D ratio: The longer screw design aims for improved mixing and a more stable flow, enhancing your filament production.

- Potentially higher output: More flights pushing forward the unmelted plastic in the hopper zone, ensuring higher output and more stable pressure. So you’ll be able to produce more filament in less time, meeting the demands of larger projects without compromising quality.

- Preventing premature melting: The longer screw creates a heat break between the heat zones and the hopper zone, which prevents premature melting – this is detrimental for keeping the material flow going.

The second change is an upgraded stepper motor with more power, combined with a more efficient gearbox to transfer that power to the drive screw.

The added motor power can better overcome variations in input material, making for a much smoother rotation of the screw. This leads to far more consistent output. 3DEVO says the RPM rates are “extremely stable”; variable rates cause differences in filament diameter, which are not desirable.

3DEVO has also redesigned the Filament Maker TWO to be far easier to maintain. You can easily remove the screw and barrel for cleaning, something you’d want to do when switching materials.

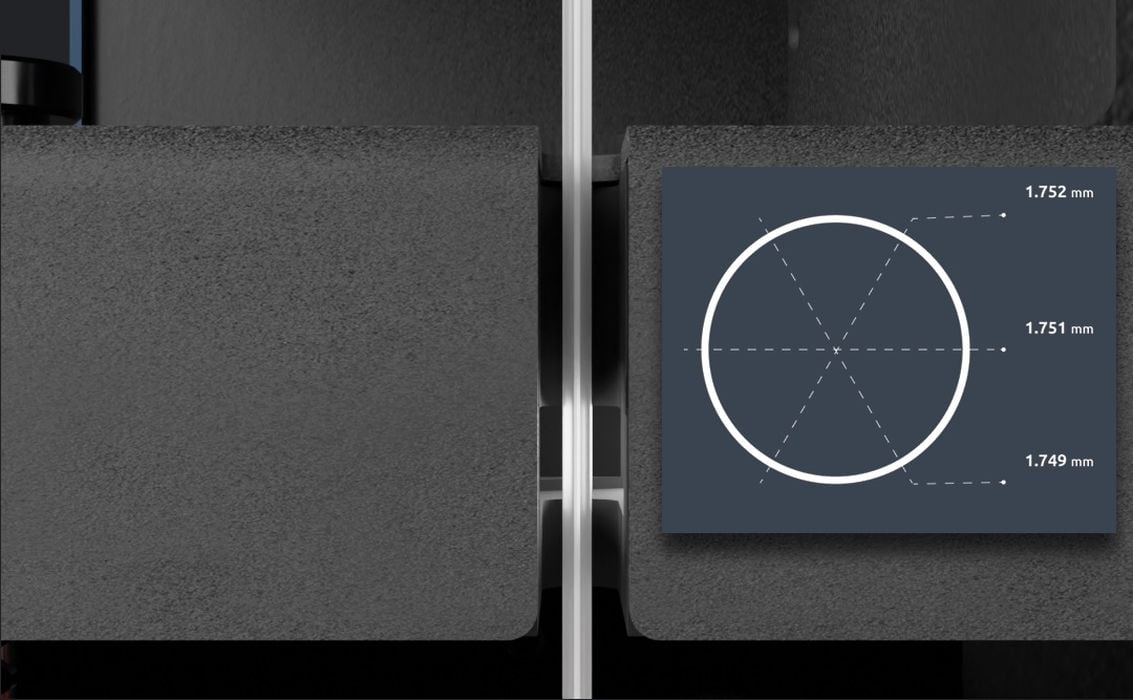

Another very interesting improvement is the use of not two, but three camera sensors. These are set up at 120-degree angles on the extruded filament and keep track of not only the diameter in three directions, but also the ovality of the filament. Many filament production lines use only two sensor axes, but here there are three. This should lead to increased filament quality, at least geometrically.

They’ve also added an ability to remotely control and monitor the Filament Maker TWO for operator convenience, and maintain detailed data logs of activity for subsequent analysis.

Finally, the Filament Maker TWO is now able to handle 3kg spools, enabling production of larger quantities of material in a single job.

The new device seems to have all the right features, and clearly 3DEVO has been listening to customers.

But should you be a customer? The price of the Filament Maker TWO is €16,995 (US$18,260), with a new ability to rent the device for short periods if required at US$600/month.

The price of the Filament Maker TWO is far beyond what is affordable for hobbyists seeking a way to make cheap filament. That’s not what this machine is for.

It’s instead targeted at institutions and organizations that are doing one of two activities:

- Developing a new filament mix and requiring an ability to make small quantities of spools iteratively

- Requiring low volumes of a proprietary filament mix not available on the market, so they make it themselves

If that’s you, then you’d better check out the new Filament Maker TWO from 3DEVO.

Via 3DEVO