We had a look at 3devo’s new Filament Maker TWO.

The Utrecht-based company produces what is likely the only practical desktop 3D printer filament manufacturing device, somehow surviving countless other attempts that mostly failed miserably.

Producing filament would at first seem to be a simple operation: melt some plastic pellets, push them through a nozzle, and roll it up on a spool.

That is far away from the truth— it’s not funny: 3D printer filament must be extraordinarily consistent in diameter, roundness, and composition. To achieve this, the manufacturing process must include extremely precise measurement and control of speeds, humidity, and temperature.

3devo’s devices have achieved this, and as a result, their systems have gained acceptance in the market. However, that market is NOT desktop 3D printer operators hoping to recycle their 3D print scraps. That’s because the 3devo system is still fairly expensive for individuals at something close to US$20K per system. Instead, 3devo’s market is institutions, research labs, and other organizations that need to make filament they cannot purchase. Instead, they make it themselves using 3devo equipment.

The new Filament Maker TWO is the latest iteration of the technology from 3devo. From my discussions with the company, the system incorporates a wide range of convenience improvements.

These include a removable die, extra ports, easy disassembly for maintenance, and the ability to clean the device (for swapping materials) in only 30 minutes. A filter removes emissions during operation. They also now market a variety of spare parts in their online shop.

The Filament Maker TWO produces even better filament due to a longer screw and more powerful motor, which provide a more consistent flow of material out the nozzle, particularly when irregular input chunks are encountered.

The device now includes data logging and has an API for operators to implement various types of customization and control.

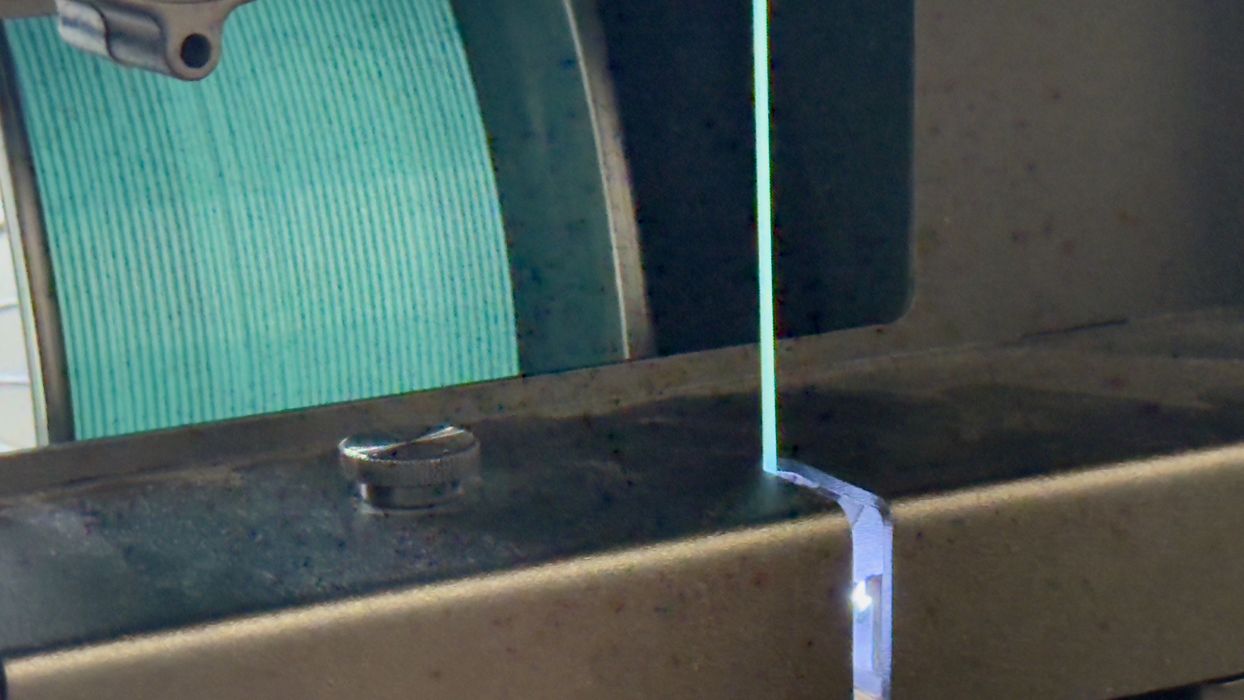

A unique feature is a three-way diameter sensor. This sensor monitors the diameter of the filament as it is produced, and provides feedback to the system to adjust speeds and feeds to maintain the diameter within tolerance levels.

Most filament production lines include a two-way sensor to measure diameter, but the Filament Maker TWO has three sensors that, when combined, help ensure the filament is not only the correct diameter but also round.

3devo explained that many of the new features were inspired by feedback from customers, so it’s likely the new machine will be popular.

I discussed the typical usage of these filament makers with 3devo, and many of their customers are using them to produce experimental or unusual filaments. For this reason, the company introduced a rental program. This allows an organization to use the equipment on a temporary basis, during a project, for example.

That said, 3devo also explained that they now have a few customers using their equipment for production. Low-volume production, to be sure, but production of unusual and unique filaments for internal use.

Via 3devo