3DEO is growing, but in more ways than one.

The California-based company provides a metal 3D printing service. They’ve been around for quite a few years now, and have focused on the production of small metal parts, as we’ve previously reported.

However, this year things seem to be changing. The company received a significant amount of investment earlier this year, and there are additional investments in process. They’ve also made a notable partnership with IHI AEROSPACE Co. to produce parts in volume, and I get the impression IHI may have also invested in 3DEO.

That’s good news for 3DEO, which has so far received, according to TechCrunch, US$36.4M in investment. Whatever the new investments may be, they could push the total over US$50M, placing 3DEO among the more well-funded 3D print companies.

I asked 3DEO about their technology, and it turns out it hasn’t changed in recent times. They use some form of binder jet approach to produce small metal parts. Because they operate as a service, they don’t need to explain much about it: they just make parts on request.

However, there has been a change in the USE of the technology. Because of their increasing contacts with new partners they’ve realized that their 3D printing process can be used to produce larger parts. They describe this as a “mindset change”, rather than a technological change.

We’re still not talking about “large format” parts that are made with specialized machines, but instead 3DEO is able to produce parts larger than they have traditionally done. That, in turn, opens up their technology to more applications and customers.

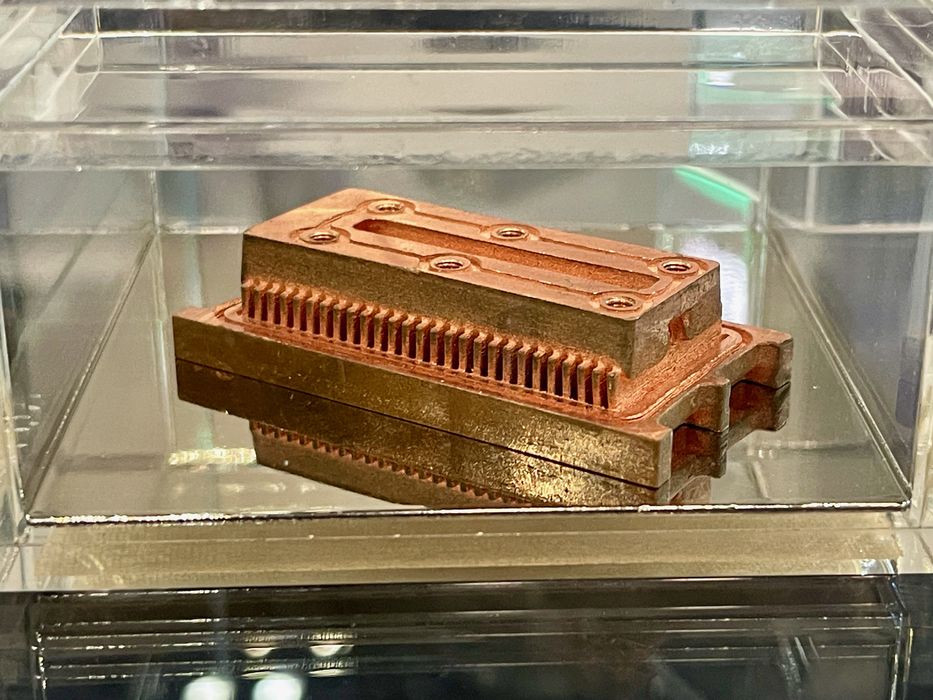

They’ve also broadened their material selection, which now offers 17-4PH stainless steel, 316L stainless steel and copper. We’re told they are working on additional materials that could be announced soon.

All of this widens the application envelope for 3DEO.

Finally, they’ve also discovered an effective approach for growing their business. They often start with prototyping with customers, but then eventually transform the work into ongoing production that can last for longer periods. They’ve adjusted their internal processes to leverage this strategy, and it seems to be quite effective for them.

3DEO has come a long way since their inception, and now appears to have mature technology that can be scaled up in the market.

Via 3DEO