Let’s take a nostalgic look at four unusual 3D print technologies that didn’t quite make it.

While the industry today seems to be converging on a few key 3D printing processes, that wasn’t always the case. Years ago dozens of companies launched with a wide range of unique 3D printing processes, all attempting to test the market.

Some survived, and those are mainly the technologies we see today, while others did not gain sufficient acceptance in the market. Let’s take a look at four that I’ve personally encountered that were, at the time, quite interesting.

Blueprinter

Blueprinter was a Danish startup company that hoped to reduce the cost of SLS technology. SLS is usually quite expensive because of the requirement to use a pricey laser system to fuse polymer powder.

Blueprinter’s approach was to instead use a thermal electric printhead to fuse material to avoid the price of the laser components, and it worked reasonably well.

However, the price point of the company’s technology was in an awkward position, between inexpensive desktop FFF devices and more pricey commercial SLS systems. What sealed their fate was most likely HP’s introduction of MJF technology, which provided similar results and had the backing of a huge corporation.

Solido

Solido, an Israeli company, had a very unique 3D printing process, Plastic Sheet Lamination (PSL).

Instead of extrusion or resin polymerization, the company used plastic sheets as material. The idea was to glue a series of very thin PVC sheets together, but cut the outline of each layer’s shape with a knife. After printing, the excess material could be pulled away to reveal the final object.

Their approach never caught on, even though it could produce reasonably strong parts, at least for that era. There were severe limitations in material, however, and the print speeds were said to be quite slow.

Unfortunately the company closed down by 2011.

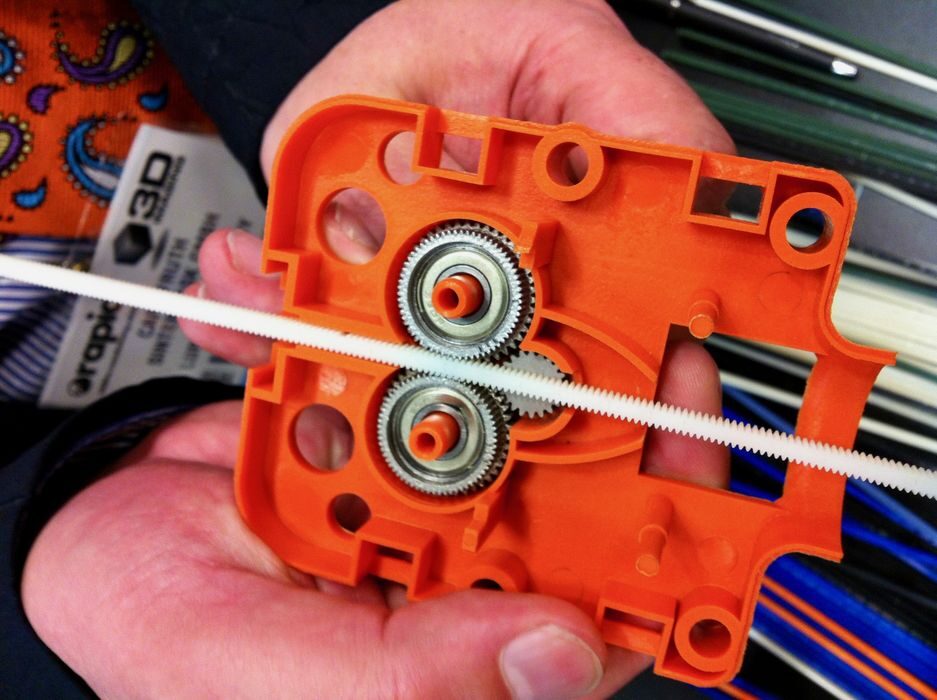

Fabbster

Fabbster was a brand of desktop 3D printer made by German company Sintermask. The device was their venture into the then exploding desktop 3D printer market, along with others like MakerBot, Ultimaker and Solidoodle.

At first glance the Fabbster, which was sold as a kit like many at that time, would appear to be a basic cartesian-style FFF 3D printer. However, it had the most unusual material system.

Instead of filament, the Fabbster used “sticks”. These were short segments of custom made plastic that included teeth for the extruder to grab firmly.

At the end of the stick was a small hook that could be used to link a second stick, and so on. It was possible to print larger objects by stringing many of these sticks together. It was also possible to switch colors in mid print by linking a different color stick.

In retrospect there was so much wrong with this approach: how do you handle long jobs? How do you switch colors at the proper moment? Where do you get these weird sticks? What materials would be available? It’s not surprising Fabbster didn’t last very long.

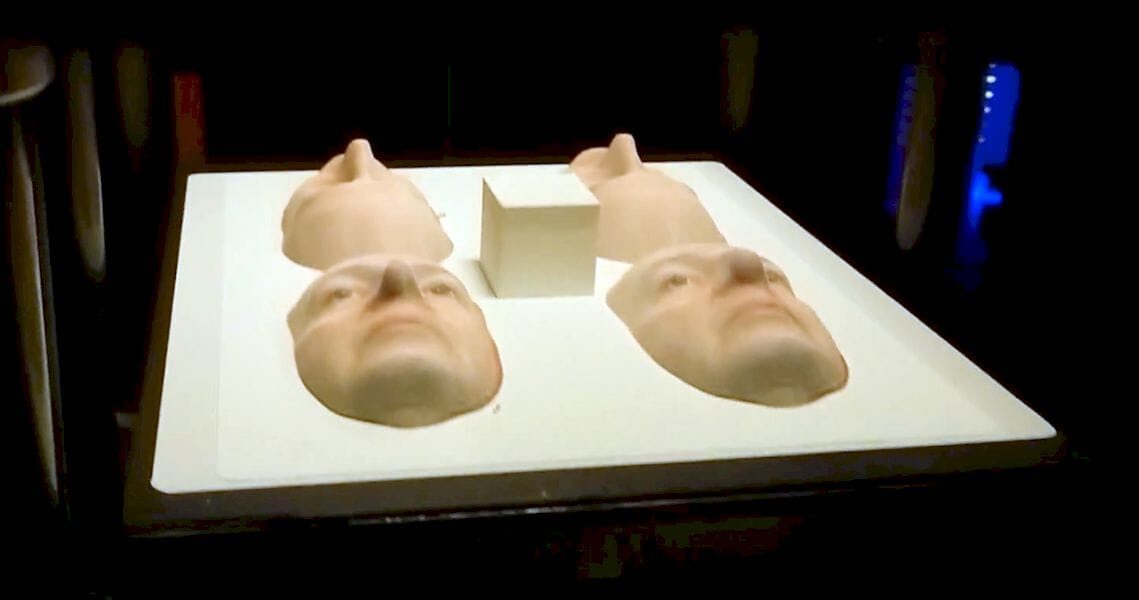

MCOR Technologies

Finally, we have MCOR Technologies. This Irish company produced a unique 3D printer that used plain paper as its material. Similar to Solido, the paper would be glued together and cut on each layer — but paper is much less expensive.

MCOR did something different, however: they integrated a standard 2D color inkjet printhead into their Arke system. The idea was to perform a standard 2D paper color print on each layer, coloring the edge of the object.

This meant that after the excess cutaway paper was removed, you’d have a decent, full color object — made of paper and glue.

In spite of the system working, the company eventually shut down in 2019. It turned out the market for full color objects made from relatively weak paper material wasn’t as big as thought. It’s also possible that those seeking color prototypes may have wanted more brilliant color than could be produced with this approach.

There are plenty more companies similar to these four, all experimenting with 3D printing concepts that, for one reason or another, didn’t make it all the way to the finish line.

Today there are still unusual 3D printing processes appearing from time to time, and perhaps someday I’ll be writing a similar story about them.