Charles R. Goulding and Preeti Sulibhavi delve into the $26.6 billion merger that creates America’s top clean energy provider and integrates groundbreaking 3D printing technologies.

Constellation Energy, the leading U.S. producer of nuclear-powered, 24/7 emissions-free electricity, has announced its agreement to acquire Calpine Corporation, the nation’s largest generator of electricity from natural gas and geothermal resources, for approximately US$26.6 billion. The account will result in a company with 2.5 million utility customers and provide Constellation with leading market share in Texas, the fastest-growing market for power.

This strategic move is set to create America’s foremost provider of clean and reliable energy, enhancing the combined entity’s capacity to meet the growing energy demands of customers and communities nationwide.

3D Printing Innovations in Energy Sectors

3D printing, or additive manufacturing, has been revolutionizing various industries, including the energy sector. We recently published a Fabbaloo article about how the Tennessee Valley Authority (TVA) intends to use 3D printing for a wide range of utilities infrastructure components. In addition to the TVA, we have covered Oak Ridge National Laboratory’s (ORNL) efforts with 3D printing technologies as well.

Its applications span multiple domains, offering efficiency improvements, cost reductions, and innovative solutions.

Applications in Nuclear Energy

In the nuclear sector, 3D printing has been instrumental in producing complex components with high precision. For instance, researchers have successfully fabricated fuel assembly brackets and other reactor components using additive manufacturing, resulting in reduced production times and enhanced material properties. Additionally, 3D printing has facilitated the development of advanced reactor designs by enabling the creation of intricate geometries that were previously challenging to manufacture.

Applications in Other Energy Sectors

Beyond nuclear energy, 3D printing has found applications in the production of turbine blades for wind energy, allowing for customized designs that improve aerodynamic performance. In the oil and gas industry, 3D printing has been used to produce durable parts for drilling equipment, reducing downtime and maintenance costs. These advancements demonstrate the versatility and transformative potential of 3D printing across various energy sectors.

Constellation Energy has demonstrated an interest in 3D printing technology, particularly in its potential applications within the energy sector. The company has engaged in initiatives that promote the use of this technology.

Educational Initiatives

Through its partnership with the Cal Ripken, Sr. Foundation, Constellation has supported educational programs that provide students with hands-on experiences in various technologies, including 3D printing. These programs aim to foster collaboration and problem-solving skills among students, preparing them for future technological advancements.

Advocacy and Information Sharing

Constellation has also provided resources and information on the benefits and business applications of 3D printing. In a Constellation Blog post, the company discusses how businesses can leverage 3D printing to improve production processes, streamline repairs, and develop prototypes. This indicates Constellation’s recognition of the transformative potential of 3D printing in various industries, including energy.

Energy Efficiency Considerations

Additionally, Constellation has addressed the energy consumption aspects of 3D printing. In discussions about energy-efficient office equipment, the company highlights the importance of considering the energy use of 3D printers, suggesting that businesses look for ENERGY STAR-certified models to ensure optimal energy efficiency.

While direct applications of 3D printing within Constellation’s operational processes are not prominently featured in publicly available sources, the company’s involvement in educational initiatives and information dissemination reflects its acknowledgment of the significance of 3D printing technology in the evolving energy landscape.

In the broader nuclear energy sector, 3D printing has been utilized to produce complex components with high precision, enhancing production times and material properties. For example, Westinghouse has developed 3D printed nozzles to improve nuclear power operations.

These advancements demonstrate the potential benefits that companies like Constellation could achieve by integrating 3D printing technologies into their operations.

Enhanced Inspection Initiatives

Researchers at two Department of Energy (DoE) laboratories, Idaho National Laboratory (INL) and the ORNL, have developed technology that uses a software algorithm to check for flaws in 3D printed nuclear components and helps identify promising metal alloys for 3D printing the next generation nuclear reactors.

The recent research partnership began after INL encountered a logistical challenge when linking defects to specific printing parameters. Researchers needed to scan more than 30 samples to identify patterns, but each scan took 30 hours. Before paring down the effort, Chuirazzi consulted ORNL’s Ziabari. Licensing Ziabari’s algorithm enabled the collection of all the data in a timely way. “Including prep, it now takes about 15% of the time it did to scan something with our setup,” said Chuirazzi. “We can do three scans in the amount of time it took us to complete one.”

In the nuclear sector, it could substantially accelerate the development and characterization of structural materials and fuels for advanced or high-temperature gas reactors, molten salt reactors, and small modular reactors.

Calpine’s Recent Initiatives

Calpine has been actively involved in several projects aimed at enhancing energy production and sustainability. Notably, the company has executed full-scale carbon capture and storage (CCS) demonstration projects, such as the Baytown Decarbonization Project in Houston, Texas, which the Department of Energy (DoE) awarded up to US$270 million; and, the US$8.6 million Sutter Decarbonization Project in Sutter County, California. These initiatives, supported by cost-sharing agreements with the Department of Energy, aim to reduce carbon emissions from natural gas power plants, contributing to cleaner energy production.

In addition to its CCS projects, Calpine has expanded its geothermal energy portfolio, operating the largest geothermal generation operation in the U.S. This expansion underscores Calpine’s commitment to diversifying its energy sources and investing in renewable energy technologies.

Integration of 3D Printing in Carbon Capture Processes

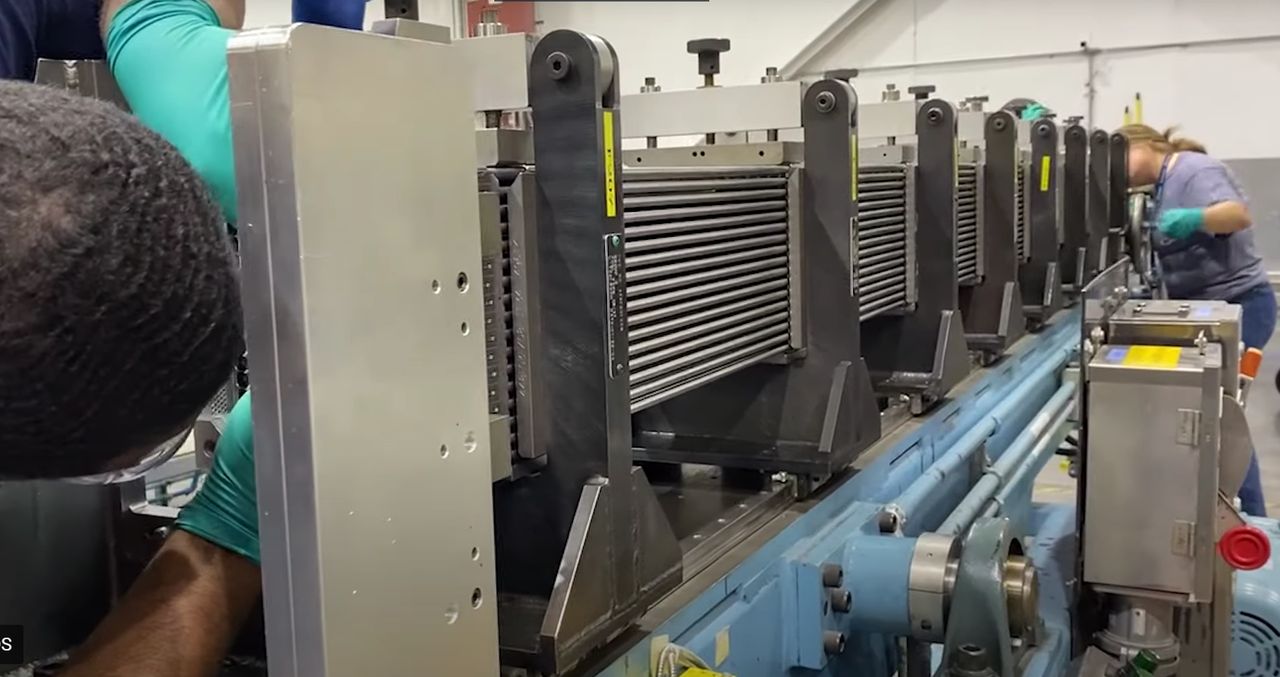

The integration of 3D printing technology into carbon capture processes presents significant opportunities for efficiency improvements. Additive manufacturing can be utilized to create customized components for carbon capture systems, such as optimized solvent contactors and heat exchangers, enhancing the overall performance of CCS technologies. Furthermore, 3D printing allows for rapid prototyping and testing of new designs, accelerating the development of more effective carbon capture solutions.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes are typically eligible expenses toward the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software can also be an eligible R&D expense. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit-eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

The acquisition of Calpine by Constellation Energy is poised to create a powerhouse in the U.S. energy market, combining Constellation’s expertise in nuclear energy with Calpine’s strengths in natural gas and geothermal power generation. This merger is expected to enhance the combined company’s ability to provide a diverse array of energy products and services, meeting the evolving demands of consumers and contributing to the nation’s clean energy goals.

Additionally, the combined entity’s expanded portfolio, including significant investments in carbon capture and renewable energy projects, positions it to play a pivotal role in the transition toward a more sustainable energy landscape. The integration of advanced technologies, such as 3D printing, further underscores the company’s commitment to innovation and efficiency in energy production.