Charles R. Goulding and Preeti Sulibhavi reveal how 3D printing technology surged forward, reshaping defense, healthcare, and other sectors despite global economic pressures.

What a year it has been. The year 2024 was another one for the record books. It’s been a tumultuous year with two wars and a presidential election.

A few years ago we reviewed Clayton Christensen’s book, “The Innovator’s Dilemma: 3D Printing and Disruptive Technology.” It explained how 3D printing is another way to disrupt the traditional business model and think innovatively. Now, in 2024, 3D printing continued to grow across various industries, with five sectors standing out to us in terms of innovation and adoption:

1. Aerospace and Defense

With 2 continuing wars in the Ukraine and the Middle East, the defense industry experienced major growth. The defense industry is increasingly using 3D technology and multiple branches of the U.S. and other nations military have made 3DP a priority. We recently wrote about the defense industries additional $52 Billion (cite) in free cash flow.

3D printing has been a cornerstone of the aerospace and defense industries. Companies like Lockheed Martin and Airbus use 3D printing to produce lightweight yet durable components, reducing material waste and production time. AM is particularly useful in creating complex geometries for parts that need to withstand extreme conditions, like in space exploration and military applications. As supply chain issues persist due to global geopolitical tensions, 3D printing offers an efficient alternative to traditional manufacturing for critical, hard-to-source parts.

A huge multi-tier supply chain supports Boeing. Successive years of major issues have irreparably damaged that supply chain. Absent this disruption the Tier suppliers would have embraced numerous new 3D products and technologies.

2. Healthcare and Bioprinting

Healthcare is experiencing a revolution with the rise of bioprinting—a subset of 3D printing that creates living tissues and organs. Companies like CELLINK, Organovo and Cyfuse Biomedical lead in producing human tissues for research and potential transplants. Beyond bioprinting, the sector uses 3D printing for custom prosthetics, dental implants, and surgical tools. The precision and customization allowed by 3D printing reduce costs and improve patient outcomes, making it a key player in medical device manufacturing.

3. Automotive

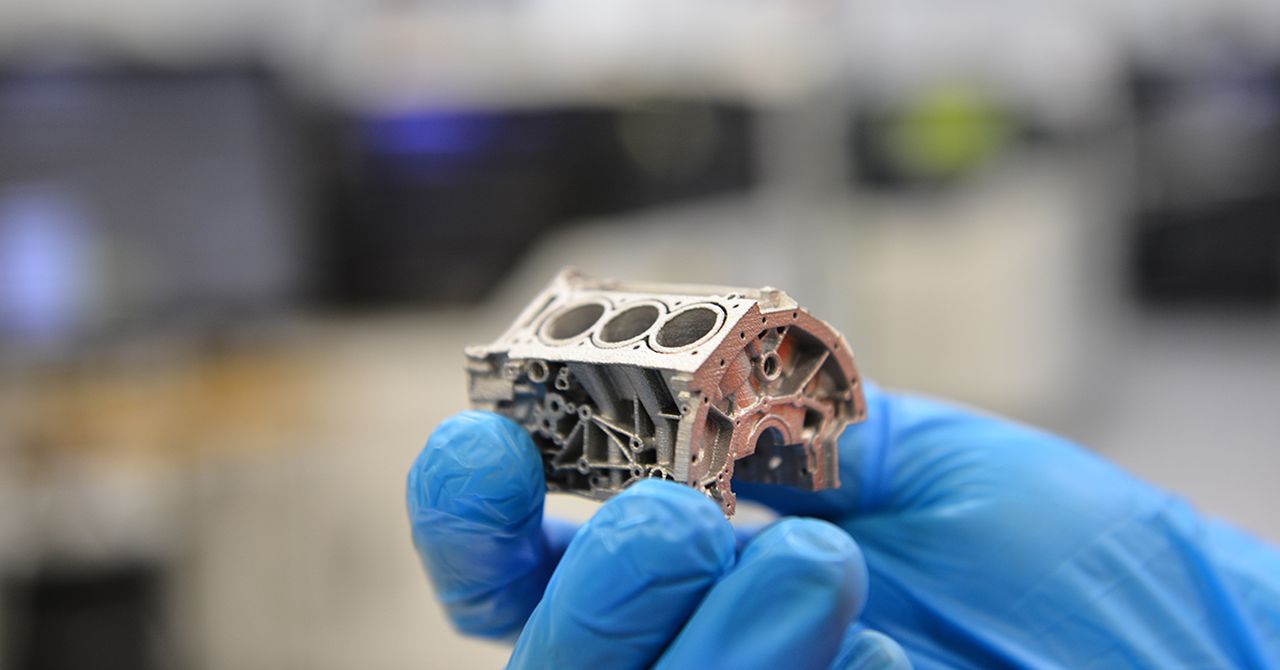

The automotive industry has fully embraced 3D printing for rapid prototyping, design flexibility, and the creation of lightweight, high-performance parts. Companies like Ford and BMW are not just using AM for prototypes but are integrating it into mass production for car components. This shift reduces lead times and allows manufacturers to build more energy-efficient vehicles. The ability to 3D print with metals and advanced polymers enhances vehicle safety by producing parts with better mechanical properties. Ford has a patent-pending in collaboration with ExOne to 3D print engine block models using a binder jetting aluminum alloy.

4. Consumer Goods and Electronics

The consumer electronics industry has increasingly adopted 3D printing for mass production rather than just prototyping. By using AM, manufacturers can consolidate parts, improve design flexibility, and speed up the development of products like smartphones and wearables. Apple, Meta, and Sony are some of the companies integrating 3D printing into their workflows to stay competitive and meet consumer demand for cutting-edge devices. Additionally, AM helps create complex designs that were previously impossible with traditional manufacturing methods.

5. Construction

The construction sector is experiencing significant changes thanks to large-scale 3D printing. Companies like ICON are leading the way in using AM to build homes more affordably and quickly. There is an acute shortage of affordable housing in many areas of the world. 3D printing is particularly beneficial for sustainable housing projects, allowing builders to create structures with less material waste and lower costs. The ability to print houses directly on-site reduces labor and transportation costs, making this technology especially promising for disaster relief and low-income housing.

6. Economic Challenges for Start-Ups

Higher interest rates and R&D expense capitalization rules have adversely impacted 3D printing startups and perhaps more importantly companies that rely on 3D printing applications including space and government grant-dependent startups. Even established 3D printing companies suffered with Shapeways going bankrupt and Velo shrinking in economic value.

3D printing startups that are less than five years old and have under US$5 million in sales, should take advantage of the R&D Tax Credit Start-up tax provision, which can provide up to US$500,000 per year in payroll tax rebates for up to five years.

7. Israel’s Economic Decline

The sustained war has adversely impacted Israel’s economy with the Bank of Israel indicating they expect the war to cost an estimated US$67 billion by 2025. Pre-war Israel was a technological powerhouse, but large numbers of the workforce have been called up to serve. Some leading 3D printing companies including Nano Dimension, Stratasys, and 3DSystems are headquartered in Israel. We recently wrote a Fabbaloo article about the challenges Rafael, Israel’s leading defense contractor was experiencing with a prolonged war.

8. Drones

The wars described above are primary drone wars. Drones are typically manufactured with 3D printing technology. In war, they become consumables with a need to replenish large unit volumes. Drones have become so effective that they make current tank technology incentives. With drones destroying US$10,000,000 per cost unit of Abrams tanks, these tank defenses need to be completely re-engineered

9. India’s High Growth Economy

India has been in the news as we have reported several times this past year. The Country has experienced an economic shift in recent years that is supported by a budget that involves a comprehensive range of changes to custom duties and a wide range of other business taxes. The opportunities for the 3D printing industry to take advantage of these tax incentives, and the overall economic shift in tax policy, in India are wide-ranging. There’s no better time than now for the 3D printing industry to invest in India.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit-eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

These nine areas demonstrate the diverse applications of 3D printing in 2024, from healthcare advancements to large-scale housing solutions. As technology matures, the range of materials and its integration into mass production workflows will continue to grow, driving further innovation across sectors. Cheers to the year that was 2024!