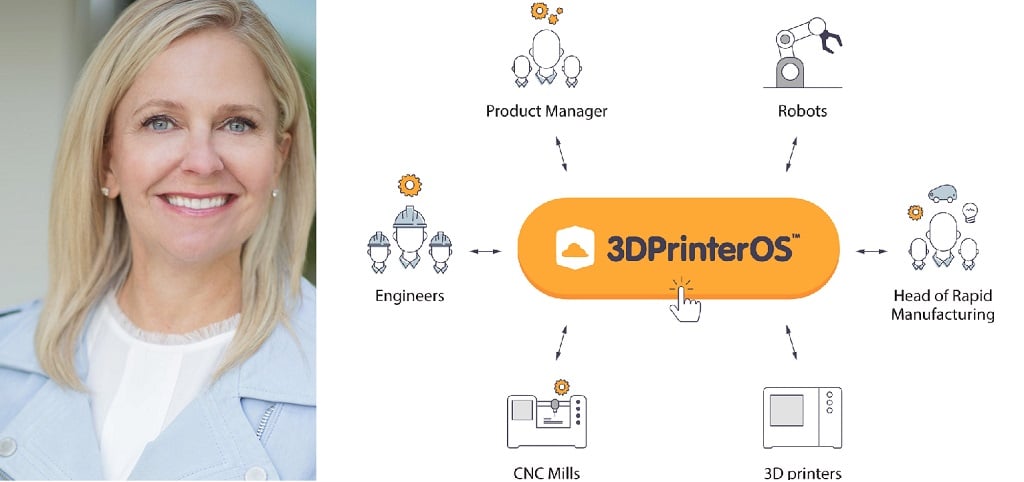

3D printing workflow management company 3DPrinterOS has appointed a new CEO; we catch up with Michelle Bockman for a chat about what’s next for the team.

I first met Michelle a few years ago when she joined HP’s leadership team in their 3D printing business. At HP, she continued on what I quickly learned was a career-long pursuit of moving the analog to the digital, and inspiring the teams around her as she did so. She was the General Manager and Global Head of 3D Printing and Digital Manufacturing – Automotive & High-Value Applications, a position she effectively created and tailored to her unique skill set as a leader in digital manufacturing with a very technical background.

Rather than wait on the press release, I went to the source with a few questions for Michelle to learn more about how she turned toward 3DPrinterOS and where she sees the next stages of growth for the company.

Fabbaloo: Can you share a bit of your professional background to date?

Michelle Bockman: “I started my career as a Mechanical Engineer in the automotive industry in manufacturing and design, which is fundamental for how I think about my passions and drive today. I spent most of my career working at GE leading P&Ls. Early on, I held other roles in automation, customer field service, and manufacturing/supply chain, then moved into the digital industrial market. At GE Digital, I was responsible for bringing software and hardware together in industrial cybersecurity, connecting machines in factories, and driving efficiencies via apps that enabled customer outcomes. Continuing into the disruptive industries, I moved to HP 3D Printing and Digital Manufacturing, ultimately leading the automotive business after an initial focus on developing new applications, business development, and partnerships.”

Fabbaloo: What led you to connect with the 3D Control Systems / 3DPrinterOS mission initially in joining its Board of Advisors and then step into the role of CEO?

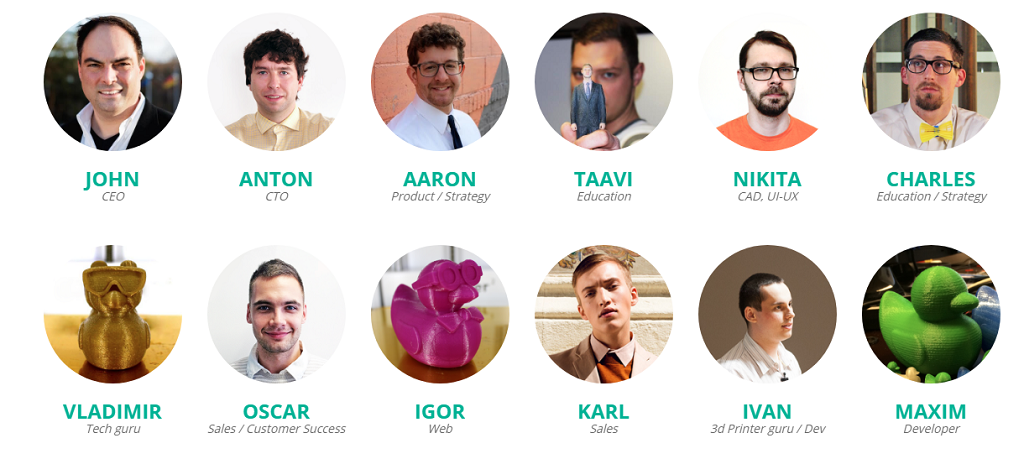

MB: “At the beginning of the year, John Dogru, President, Chief Architect, and Founder of 3D Control Systems, and I started communicating about their mission. I was drawn to the end-to-end software platform that focused first in 3D printing because I saw an industry gap. It is a bonafide operating system that securely connects the design through end-part and is incredibly easy to use; however, it has a great deal of additional functionality that can be turned on if customers need it. The company is OEM 3D printer-agnostic, so there is no partiality to one company or another. I was impressed with how this small team, with very little funding, achieved profitability, for 3 years straight and decided to invest and become an advisor for this progressive company that I see as driving the necessary next step in Industry 4.0. As we started working with customers, John asked me if I’d be interested in becoming CEO to help scale the business. I jumped at the opportunity as it was precisely the type of company I wanted to work for….software platform driving new capabilities in the hardware area (ie digital manufacturing).”

Fabbaloo: How did your past experiences with big-name companies like GE and HP pave the way to moving into more of a startup on the software scene?

MB: “For quite some time, I’ve been reflecting on my career and thinking about the roles during which I had the most fun and where I drove the most impact. As I did this, I came to the realization that when I worked at GE (and HP), I was most happy in the ‘startups’ incubated within the corporations. Fortunately, I had significant exposure in this area and the area of acquisitions. These experiences required me to think differently, scale the business, and be prepared to turn around the operations. I know that a startup on its own is very different from being under the protective umbrella of a large corporation. However, I was ready to go for it! I decided to focus on the digital industrial type of startup where I could make an impact. It was then that John and I started talking and eventually agreed to work together as we had a shared vision.”

Fabbaloo: Much of your drive has seemed to center around inspiring the teams you lead; how will this translate to your work with 3DPrinterOS?

MB: “First of all, thank you for the nice compliment. I genuinely enjoy leading teams and cultivating next-gen leaders. I think I will be able to continue my mission inside 3DPrinterOS as well as our industry. We have quite a few women in our organization, and I cannot wait to work with them!”

Fabbaloo: The current 3DPrinterOS executive team seems to be a bit of a boys’ club. How does that fit into your experiences, as one of the only, if not the only, women in the tech room, especially given your track record for inspiring more young girls to look into STEM areas of study?

MB: “I went to a university that is primarily an engineering school, and there weren’t many females on campus and even fewer in mechanical engineering classes, so that’s where I started noticing I was the only female in the room. This pattern continued as I went through my career, but what changed is when I became a manager and hired diverse teams to ensure diverse ideas. I am all about developing women into STEM roles, whether it’s a middle school girl, college student, or an employee looking for growth. I expect to continue to drive diversity in my role as CEO. Fortunately, 40% of our organization at 3DPrinterOS is female… of course, we are a small startup, but I think this is a good baseline for me to start.”

Fabbaloo: What can you tell us about your initial focus as CEO for 2020-2021? In the next few years? Long-term vision for the company?

MB: “My initial focus is all about scale, scale, and more scale. The business has not only proven the technology in the university space; we have delivered results with targeted industrial enterprise customers. So, while we will continue expanding our reach with new and current university customers, we need to dive deeper into the enterprise world. Large enterprise companies have tens of thousands of design engineers who have to wait days, weeks, months to 3D print a basic object. We can take the same proven technology and rapidly scale it to every enterprise in the world.

The longer term vision is to make manufacturing easy for the masses —

Phase 1) Top Ivy League Universities — Give 3DPrinterOS’s one click 3d printing access campus wide to top IVY league Universities ( early adopters ) (~100,000+ users today) MIT, Harvard, Rice, Duke, Caltech, 50+ etc. MISSION ACHIEVED

Phase 2) Fortune 5000 Companies — Provide easy campus wide 3d printing access for top Enterprises (~1M+ users) NEXT MISSION

Phase 3) Everyone 1 Billion+ people — Provide easy one click manufacturing to the masses – FINAL MISSION

Our vision is to GO BIG!”

Fabbaloo: What else should we know about your new appointment?

MB: “I am so excited to join this team to continue building on my experience in digital manufacturing and 3D printing. To see this gap in the industry and be in a position to deliver an offering to help customers run their manufacturing, maker spaces or just their dispersed 3Dprinting labs is incredible. I can’t wait to unveil the opportunity.”

Via 3DPrinterOS