Nexa3D made multiple announcements this week, each strengthening their position in the market.

The California-based company produces two types of 3D printers: SLA and SLS, both of which are noted for their large build volumes and rapid print speeds. This week they announced a significant partnership with Siemens, a brand-new material and another partnership with DSM.

Of the three announcements, the relationship with Siemens is perhaps the most significant. Siemens is a massive Germany-based corporation that provides all types of solutions for manufacturers worldwide.

One of the most important trends in manufacturing is the ability for making equipment to seamlessly integrate with other equipment in a factory, as the production of practically anything requires a series of steps to make and assemble parts into a complete and final product. Traditionally this was done manually, but today’s factories require a more sophisticated and automated approach.

Siemens is one of the leaders in this field, providing software tools for factories to connect all the points and provide significant monitoring and control features. They essentially can transform a factory with independent manufacturing devices into a single “machine” that produces the required output. This initiative is known as “Industry 4.0”.

Siemens and Nexa3D

However, in order to participate in such a scheme, manufacturing devices must abide by the data protocols by which all equipment communicate. That’s seems to be the nature of this partnership. Nexa3D explains:

“Siemens and Nexa3D today announced a collaboration designed to bring Nexa3D’s additive manufacturing production systems up to full Industry 4.0 preparedness. This partnership highlights both companies’ strong commitment to help additive manufacturing prepare for Industry 4.0 with innovative collaborations, open architecture, and predictive serviceability.”

And:

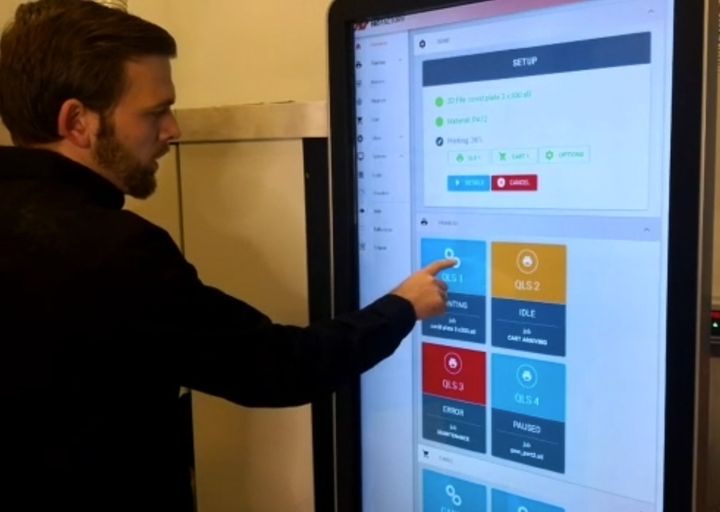

“Under this collaboration, Nexa3D’s entire Quantum Laser Sintering (QLS) product line will be standardized to Siemens’ state-of-the art factory automation and edge computing technologies. Nexa3D plans commercial delivery of its QLS-350 polymer production 3D printer powered by Siemens’ automation controls in the first quarter of 2021.”

This means that if a manufacturer using Industry 4.0 protocols sought a SLS 3D printer, Nexa3D’s products would certainly be considered. Without this certification they would not have been considered in that situation. The result is that Nexa3D’s market just got a bit bigger, as the partnership unlocks access to Industry 4.0 prospects.

xCE-White 3D Print Speed

The second announcement deals with a new material from Nexa3D: xCE-White. This is a resin material intended for use in the company’s NXE400 3D SLA 3D printer. While xCE-White is a strong and robust material suitable for a number of applications, its main claim to fame is its curing speed.

Evidently Nexa3D was able to devise a way for this photopolymer resin to cure as much as 20X faster than alternative resins. This means that the 3D printing process will proceed quite a bit faster as the light source does not have to linger on each voxel as long. The result is far speedier 3D prints. With resin 3D printers, chemistry is king.

Nexa3D x DSM Partnership

Finally, the company announced a relationship with Royal DSM, a large and well-known European chemical company that has been recently been establishing a number of partnerships with 3D print-related organizations.

Now, there’s another partnership, this time with Nexa3D. Royal DSM says:

“Royal DSM and Nexa3D today announced a partnership to fast track the availability of Nexa3D’s QLS-350 systems with DSM’s supply chain-approved laser sintering powders for series production. Under this collaboration, Nexa3D plans to immediately include DSM’s first-ever PBT laser sintering material, Arnite T AM1210 (P), with every Quantum Laser Sintering QLS 350 system it sells commercially starting in the first quarter of 2021.”

The implication here is that Nexa3D establishes a high-quality source of materials for their SLS 3D printer equipment. This allows more choice for Nexa3D clients, and provides additional opportunities for Nexa3D to finely tune their 3D print parameters to optimize print speed and quality with these known materials.

Chemical companies typically hold enormous libraries of materials recipes and it’s only been in the past few years they have been slowly opening access to them for additive manufacturing. We’ve frequently seen arrangements where a 3D printer manufacturer gains access, sometimes exclusive access, to one or more powerful proprietary materials. It seems the Nexa3D relationship with DSM is one of those arrangements.

Nexa3D has been making quite a few moves lately beyond these three announcements. It was only last month they made a major acquisition of NXT Factory to gain the SLS product line.

I’m now wondering what they are going to announce in October.

Via Nexa3D