German startup iFactory3D has now launched their inexpensive belt 3D printer on Kickstarter.

Inspired by the 3D print community, Artur Steffen and Martin Huber developed an open source belt 3D printer design way back in 2018. They posted this design on Thingiverse, and apparently received demand from visitors to provide a kit to build the device.

Here they discuss how the project started:

While open source designs are freely available, that doesn’t mean anyone is capable of sourcing the parts and putting them all together. In reality, there are relatively few people that can do so compared to the masses who cannot. To address their needs, Huber and Steffen decided to create a company to do so.

They’ve done so and they’ve just now launched the iFactory3D One belt 3D printer on Kickstarter.

Belt 3D Printers

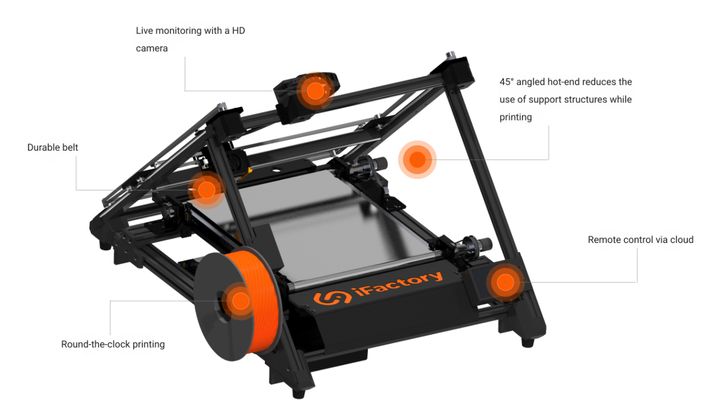

For those unfamiliar with the belt concept, it is quite different from standard fixed-plate 3D printers that print vertically. Instead, a belt 3D printer prints at a 45 degree angle on a slowly moving conveyor belt.

This configuration provides three main benefits:

- Potentially continuous production, as completed prints simply roll off the end, and production continues until you run out of filament

- Potentially infinitely long 3D prints, as there is no limiting dimension on the constantly-turning belt; you can print very long objects if supported when they come out of the device

- Simplified support structures because the 45 degree angle allows a different perspective on the model’s geometry, if oriented correctly

iFactory3D One 3D Printer

The iFactory3D One 3D printer has quite reasonable specifications:

- 1.75mm filament used

- 0.4mm nozzle, swappable

- Titan Bowden extruder

- Build volume of 290 mm wide by 180 mm tall by “anything”

- 260C hot end

- Heated polymer conveyor belt, allowing printing of PLA, PETG, PC, TPU, ASA, Nylon, ABS

- Integrated blade to ensure prints successfully come off the belt

- Silent TMC stepper drivers

- Integrated camera system for remote viewing

- WiFi, SD Card USB interface

- Out-of-filament detection

- Marlin firmware that includes the usual safety features

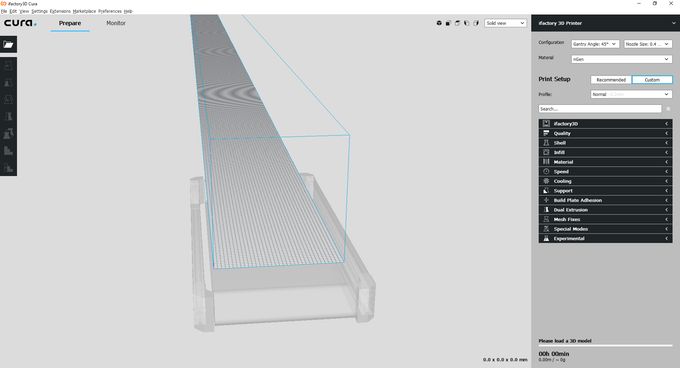

- Customized Ultimaker CURA software for belt operations

- One year warranty

There are a couple of interesting features that you might not expect on a low-cost device such as this.

First, there’s an integrated Raspberry Pi system with 3.5” color touchscreen. The Pi also runs a modified version of Octoprint that allows for full remote access, with all the benefits of Octoprint and its plug-ins. This one feature transforms the device into a “smart” 3D printer. Here’s a video showing the slicing and printing procedure:

The other feature is a bit unique and very interesting.

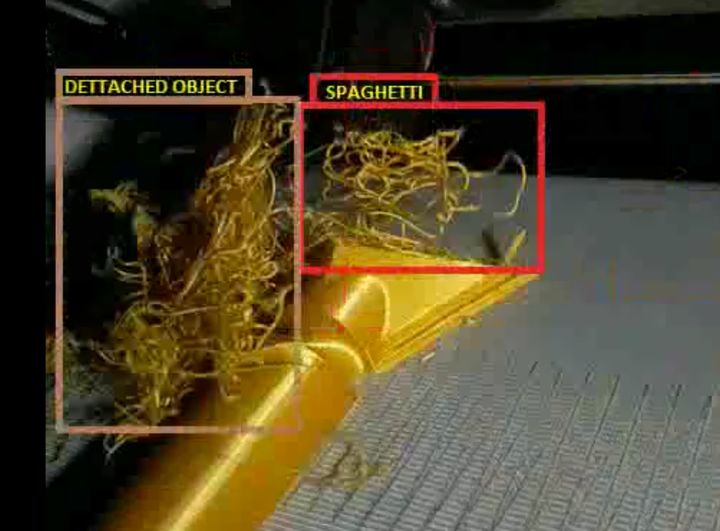

A belt 3D printer could be used for serial manufacturing purposes, and indeed that is one of the use cases promoted by iFactory3D on their Kickstarter page. In such a scenario you would risk wasting a lot of material if something went awry when unattended.

To counteract this problem, iFactory3D is to introduce a new feature they call “PrinterGUARD”. This is a vision-based AI system that can apparently use live views from the onboard camera system to immediately detect if a 3D print job has failed.

The system can detect dislodged parts or even “spaghetti”. Once this happens it can provide a notification to the operator or perhaps even stop the print job. Here you can see a view where PrinterGUARD has detected a detached object and spaghetti in the same frame:

What’s perhaps the most interesting is the cost of the device. Currently on Kickstarter they are selling this machine for only €699 (US$827), although the price will rise slightly as units are consumed.

That price is comparable with many 3D printers on the market today; a bit more than the ultra-low-cost machines, but less than more expensive devices styled as “production” by their manufacturers.

I’m hoping to be able to test an iFactory3D One soon, and I’ll be sure to tell you all about my experience.

For the iFactory3D founders, this project might be an incredibly good idea, as this sequence of events is very similar to Prusa Research’s origin story. Perhaps they too will grow to a large size.

Via iFactory3D and Kickstarter