This week’s selection is “Gears and Gear Cutting for Home Machinists” by Ivan Law.

If there’s one satisfying thing that a 3D printer can do, it’s produce the parts that make active machines. Typically this involves the use of gearing systems.

But how, exactly, does one design a gear? How big should it be? What is the tooth configuration? What speed will it turn at? How will it affect other gears?

These are questions for engineers, but some of us are not engineers and will need some assistance when designing machines for 3D printing. That’s where this book comes in.

Law’s 2018 book provides an overview of the science of gearing, and includes chapters on most of the most commonly used gearing designs, including:

- Rack and Pinion

- Bevel Wheels

- Worm Gears

There’s specific attention given to gear tooth form and sizing. It’s a relatively complex matter, actually as the teeth must fit together, obviously, but also they must fit when being rotated.

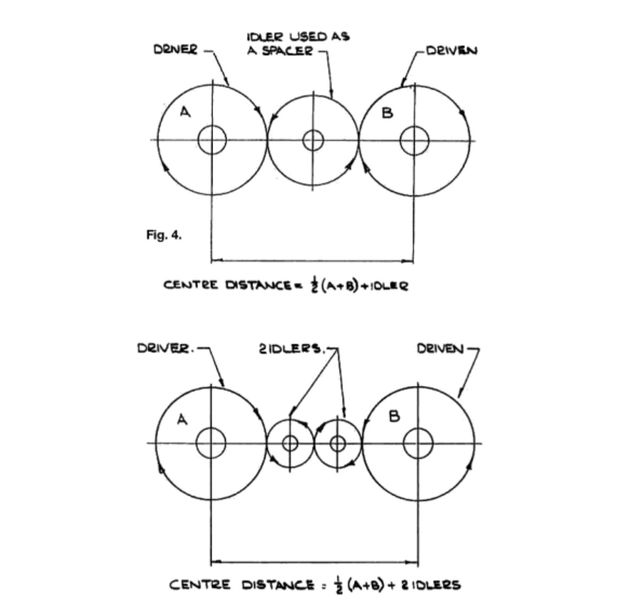

Law provides a number of formulas that can be used to calculate the effects of differing gear designs. Here we see a simple chart showing a gearing problem to be solved.

In addition to the definitions and formulas, Law also provides an overview of how to make different types of gears, such as:

- Spur gears

- Worm gears

- Worm wheels

- Bevel gears

That portion of the book may not be of particular interest to Fabbaloo readers, as you will typically 3D print the gears, rather than cutting them with traditional machining equipment.

Hopefully this book will enlighten you on the topic of gears and help you develop your next incredible 3D printed project. And it’s not very expensive, either.

Via Amazon