Researchers have been using bioprinting technology to assist in the development of COVID-19 treatments.

According to a report in the New York Times, researchers at the Wake Forest Institute for Regenerative Medicine unexpectedly discovered a new approach: 3D bioprinted miniature organs. These human-like replications mimic much of the actual body functions, and thus are ideal for use in testing.

The miniature organs, which apparently include lung and colon analogs, offer a trouble-free testing platform that doesn’t risk any human or animal well-being. In addition, these miniature organs are far more closely related, biologically, than mammals that have previously been used for testing.

There’s another advantage in that these bioprinted organ analogs can be continually monitored, unlike, say the lungs inside of a test subject, which are a bit hard to access. In this way those performing tests can directly observe the effects of their prototype treatments.

The team at the Wake Forest Institute for Regenerative Medicine is led by Dr. Anthony Atala, who has long been working on advanced bioprinting technologies. We had a story about his work in 2011, where he described the potential of future bioprinting.

It may be we are entering that future.

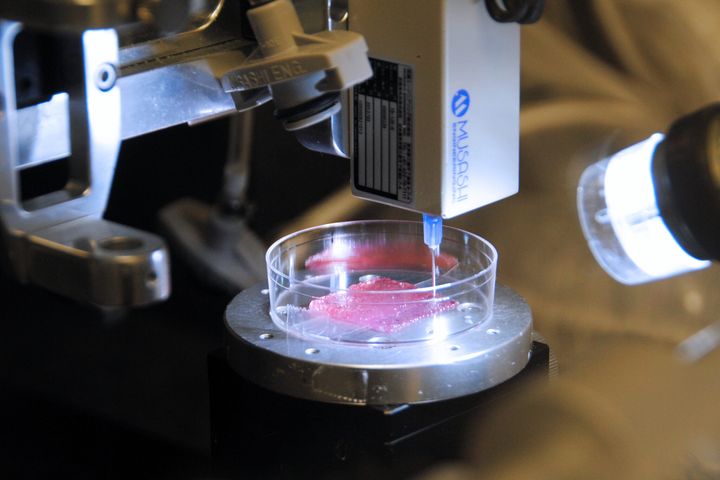

Atala’s team has previously been able to produce these human organ analogs, but had been doing so manually using tiny pipettes. Now with the worldwide demand for COVID-19 treatments and hundreds of treatment development projects requiring test platforms, the Wake Forest team managed to automate the production of these bioprints.

Now they are apparently capable of producing “thousands per hour” using 3D bioprinting techniques. After production, they are packed and shipped to research facilities.

While this work is exciting and necessary in these dark days, it is by no means demonstrating the ability to truly 3D print functioning human organs, the long-term goal of bioprinting.

These analogs are just that: they provide parallel biological and chemical reactions to simulate human tissue, but they are certainly not functioning lungs or colons. To actually produce such items there is an enormous amount of research and development yet to take place.

Nevertheless, Atala and team have embraced this new form of 3D printing application, and one that is surely welcomed by COVID-19 researchers.

In the post-COVID-19 era, which we all hope will arrive soon, I can see this approach being used as a means to dramatically reduce the use of animals for testing, not only for drug research as is being done here, but for other applications. Cosmetic testing, for example, might benefit from this approach, and it would certainly be a competitive advantage if done.