FATHOM has acquired GPI Prototype & Manufacturing Services, expanding with more DMLS 3D printing capabilities.

Last year, FATHOM was itself acquired — the whole thing can get a little bit confusing at a glance, frankly, but essentially the FATHOM brand now encompasses the original operations of Studio FATHOM as well as Midwest Composite Technologies and ICOMold, and, now, GPI.

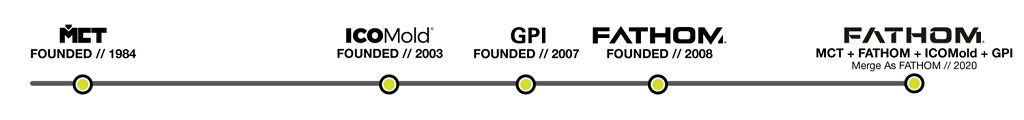

The timeline looks a little something like this:

All of these are owned by CORE Industrial Partners, operating under this FATHOM umbrella.

FATHOM Acquires GPI

Upon the 2019 merger of FATHOM and MCT under CORE, we noted that the move was creating a digital manufacturing powerhouse. That powerhouse is powering up even more now, with even more capabilities.

FATHOM notes that its offerings now include:

- 14+ Manufacturing Methods Leveraging Additive

- Subtractive & Formative Processes

- Over 125+ Industrial Machines Across 5 Facilities

- Main Services Include—But Not Limited To:

- Additive Manufacturing & 3D Printing // SLS, FDM, DMLS, MJF, SLA, and PolyJet

- 3 & 5 Axis CNC Machining

- Urethane Casting

- Injection Tooling & Molding

- Finishing & Assembly

Those metal additive manufacturing capabilities they mention? Yeah, they’ve now doubled, “creating a more encompassing DMLS solution.”

“GPI’s ability to leverage metal additive manufacturing accelerates both design cycles and time to market and further enhances FATHOM’s existing metal additive capabilities and our unique customer value proposition. We’re excited to work closely with GPI’s customers as a turnkey partner for on-demand manufacturing, providing a broad array of complementary services and an unparalleled customer experience,” FATHOM CEO Ryan Martin said.

FATHOM now offers DMLS abilities for:

- Stainless Steel (PH1, GP1, 316L)

- Cobalt Chrome (MP1)

- Maraging Steel (MS1)

- Aluminum (AlSi10Mg)

- Nickel Alloy (IN718)

- Titanium (Ti-64, ELI)

Along with those come new “EDM capabilities, additional metallurgical analysis equipment and mechanical quality assurance – In-Process Quality Assurance (IPQA) activities.”

Not only does FATHOM gain GPI’s capabilities, GPI likewise gains access to the broader FATHOM holdings to bring to its existing customers.

“Since its founding over a decade ago, GPI has been on the cutting edge of the revolutionary metal additive manufacturing space,” GPI Founder and CEO Scott Galloway said. “This partnership with FATHOM will further benefit our valued customers through an enhanced suite of manufacturing capabilities accompanied by the same excellent customer service, quality and metallurgical expertise for which we’re known.”

Terms of the transaction weren’t disclosed, though there was a note that “Monroe Capital LLC provided financing for the acquisition.”

FATHOM Digital Manufacturing

In the announcement, another interesting note arises:

“GPI is now part of the largest privately held digital manufacturing service provider in North America.”

So, that’s significant: the largest privately held digital manufacturing service provider on the continent. In September, when CORE acquired FATHOM and merged it with MCT, the statement was that they were forming “one of the largest privately held digital manufacturing service providers in North America.” The changeover from “one of the largest” to “the largest” seems to have taken place just a few months ago, when CORE brought ICOMold into the fold. The March 2020 announcement said:

“Three companies, FATHOM, Midwest Composite Technologies and ICOMold have combined to form the largest privately held digital manufacturing service provider in North America.”

So GPI is coming into what was already (as of this spring) the largest such provider, and by doing so also doing its part to ensure that that title stands.

Digital manufacturing is picking up with advanced production technologies becoming more widely available.

Service companies are critical to the ongoing pace of adoption, as they offer immediate access to knowledgeable experts trained in designing, 3D printing, and post-processing prototypes, end-use parts, and anything in between. And, of course, that’s not only 3D printing; digital manufacturing extends beyond additive manufacturing into a growing stable of advanced processes. And FATHOM’s growing installed base of both equipment and experts is proving an important access point to these technologies.

And, because we love a list, that installed base also meets necessary certifications; FATHOM notes that it holds ISO 9001 and AS9100 Rev D certifications and is ITAR registered, while GPI reports that it holds ISO 9001, ISO 13485, and AS9100D certifications. These certifications are, as we often underscore, important to ensuring smooth operations of manufacturing operations; always keep an eye out for ISO and other industry-standard certifications when selecting a service provider.

Via FATHOM