Supercar maker McLaren’s new Speedtail includes an unusual feature that might inspire some new 3D printed designs.

The Speedtail is a monster of a vehicle, as you would expect. This car can accelerate to a blistering 300km/h in only 12.8 seconds. Folks, that’s not 100km/h (60mph), that’s three times that speed — in under 13 seconds. This is a very fast car.

The car achieves that speed through a highly sophisticated design throughout, but particularly in the body. The carbon fiber body sports a very unusual feature: ailerons! They explain:

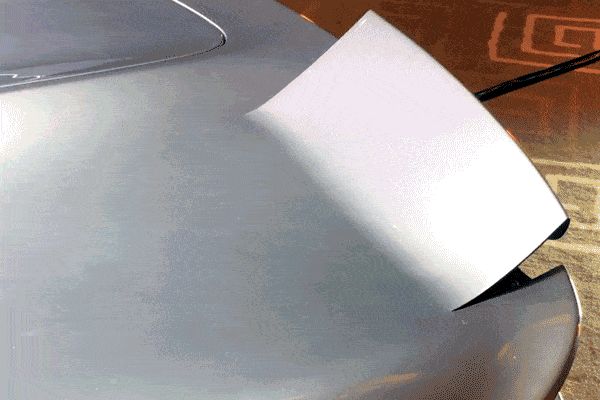

“In stunning new automotive technology, the Speedtail does away with a traditional rear wing. Instead, its trailing edge integrates controllable surface elements known as ‘ailerons’ – usually found on aircraft. These extend at high speed to provide balance and provide airbrake function. Unlike traditional hinged ailerons, however, the Speedtail’s are formed from the bodywork of the tail. There is no separate, moving element – the carbon fibre bodywork itself actually bends. This removes the need for joins or shutlines. And minimises turbulent air… with no loss of speed. Hydraulically actuated, the ailerons move the centre of pressure towards the rear, increasing downforce. The Speedtail’s active ailerons only became possible because of a relentless commitment to pushing boundaries – in both aerodynamic design and materials innovation.”

You have to see this to understand how it works:

Thus the car appears to be without a rear spoiler, but it magically appears when necessary. Amazing!

From what I can learn, it seems that the Speedtail body is produced using conventional carbon fiber layups on molds, so there’s no 3D printing technology at play here. However, this is such a fascinating design it deserves more thought.

3D Printing Rigid / Flexible Parts

We’re accustomed to 3D printing either rigid or flexible parts. Parts like stiff control arms, or squishy gaskets. But this design is something different, something “in between”.

Could hybrid rigid-flexible parts be 3D printed? In carbon fiber?

I believe they could.

All it would take is to ensure the print is thin enough to allow for bending by a sufficiently powerful motor. A part, even one from 3D printed carbon fiber, could bend in that scenario.

And we do know that McLaren has been among the automotive companies to work significantly with 3D printing capabilities for some time now.

This opens up the possibility of some highly unusual designs that may not have been considered in the industry as yet. Perhaps the Speedtail design could provide some inspiration to 3D print designers on future projects.

After all, we have to keep up with the molding folks, don’t we?

Via Road&Track and McLaren