Charles R. Goulding and Adam Friedman explore the idea of training with 3D printing while elective procedures are on hold.

As more hospitals are opening up again for elective surgeries, medical doctors and their staff need to continue to get training on elective surgery. The coronavirus has left many elective surgeries and elective surgery training to be postponed as medical employees are burdened with treating novel coronavirus-related illness. The traditional method for residents and other medical personnel to get training is to train on cadavers and dummies. 3D printing presents a great model for surgical doctors and staff to receive alternative training for their surgeries. Getting the proper training, experience, and relationships in 3D printing for medical personnel could “pay dividends” when training for elective surgeries.

The rise of 3D printing has created a more cost-effective method to prepare and train medical personnel for elective surgery. In December of 2019, the Mayo Clinic of Jacksonville, Florida formally announced they replaced ordering of cadavers with 3D printed human tissue simulators for $50, 10 times less than $5,000 per human cadaver. The Mayo Clinic printed and used the 3D simulators for their spine surgery development training and were able to focus on altered anatomy (for different and individualized spine pathologies) as well as crucial substructures.

There has been a nascent history of successful surgery with 3D printed parts in place of standard surgery replacement metallic and/or titanium parts. Walter Reed Army Medical Center and Mayo Clinic of Arizona and nationwide have 3D printed and used thousands of hip cups for elective surgery on hip joints. Many 3D printed materials for surgery can now be customized from the imaging from CT scans, MRIs, and other medical imaging. Learning how to use computer-aided design (CAD) software such as SOLIDWORKS and Autodesk offerings can help render medical imaging to a prototype or design that can be easily 3D printed.

Resources

One means of education for medical professionals is via remote learning on the computer. This education is centered on software packages that are already programmed for 3D prints and designs. Before registering or paying for an online class, below are two resources available free of charge to become familiar with 3D printing design.

For doctors to become familiar with 3D printer materials, such as resins and metal casting, the website from Stratasys is one good starting place. Stratasys has a whole array of 3D printers and is a proprietor in rapid prototyping and additive manufacturing. Besides giving course videos on using the Stratasys equipment, there are numerous courses on the different 3D printing materials such as acrylonitrile butadiene styrene (ABS), polyphenylsulfone (PPSF), and polycarbonate (PC). All of these materials undergo a fused deposition modeling (FDM) technology. For doctors and technicians who want to be able to experiment with different metals and materials, Stratasys not only have printers with such capabilities, but Stratasys’ website also contains teaching materials on how to independently handle the materials, doing molding and precision modeling. Once one has access to a 3D printer serial number from a Stratasys printer, all these relevant courses are available on the Stratasys Academy website.

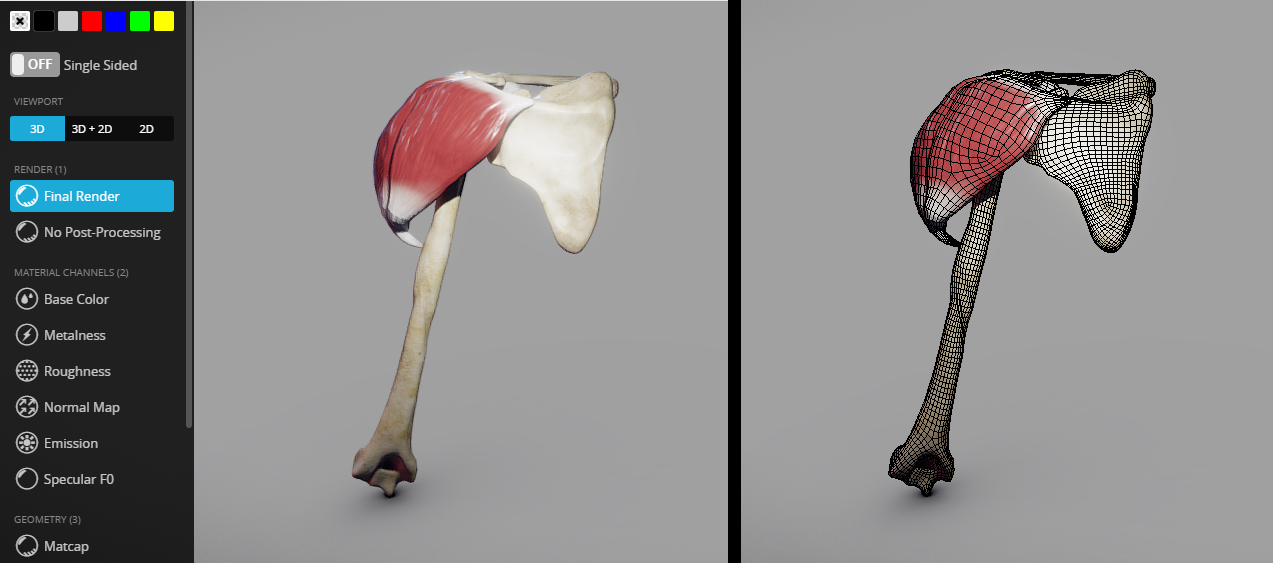

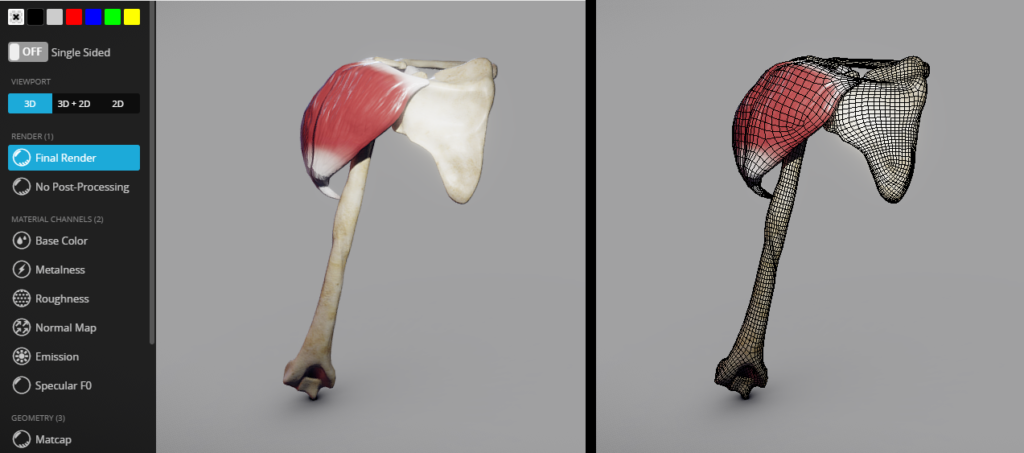

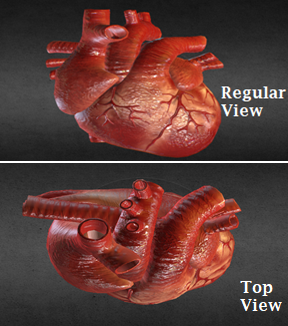

Sketchfab is a great place to start to see how 3D designs accurately portray human anatomy. The images below and most models in the Sketchfab databases are in video format. Not only can one see an angled view of a human anatomy structure to get greater precision for a 3D printed model, but one can also see the motion of that structure as it is seen inside the human body. The Sketchfab models can be printed (for a price) and sent to a 3D printer via the use of 3D printing layout software such as Blender, Cinema4D, Naker, Substance (Adobe), and VECTARY.

By going to Sketchfab and searching for any surgical specialty such as “heart” or “deltoid (shoulder blade)”, one can retrieve a 3D staging environment that rotates with mouse clicks. Below is a static image example with rotated viewpoints:

The Research & Development Tax Credit

Enacted in 1981, the now permanent Federal Research and Development (R&D) Tax Credit allows a credit that typically ranges from 4%-7% of eligible spending for new and improved products and processes. Qualified research must meet the following four criteria:

- Must be technological in nature

- Must be a component of the taxpayer’s business

- Must represent R&D in the experimental sense and generally includes all such costs related to the development or improvement of a product or process

- Must eliminate uncertainty through a process of experimentation that considers one or more alternatives

Eligible costs include US employee wages, cost of supplies consumed in the R&D process, cost of pre-production testing, US contract research expenses, and certain costs associated with developing a patent.

On December 18, 2015, President Obama signed the PATH Act, making the R&D Tax Credit permanent. Beginning in 2016, the R&D credit can be used to offset Alternative Minimum tax for companies with revenue below $50MM and, startup businesses can obtain up to $250,000 per year in payroll tax cash rebates.

Conclusion

Doctors, surgeons, and medical technicians may be postponing training in elective surgery due to the ongoing novel coronavirus epidemic that has become priority number 1 for our nation’s hospitals and medical facilities. Through course offerings and website-based tools, the medical profession can utilize 3D printing education for surgery. This will have great results for the medical surgery profession and for the medical industry at large.