Researchers at the University of Cambridge have developed a method of using holography in 3D printing.

Holography is an optical method of producing and recording a three-dimensional light field by using multiple light sources to create an interference field. You’ve likely seen holograms from time to time; they are those strange images that suddenly burst into apparent full 3D when properly illuminated.

What’s happening is that the illumination allows the recording to reproduce something close to the original interference pattern, and thus the original 3D image becomes visible.

What on Earth would this have to do with 3D printing, you ask? I did too, but it seems there are some very interesting uses for the technology, particularly when performing powder bed fusion (PBF).

PBF and SLA Issues

PBF is a common 3D printing process in which high energy, typically from a powerful laser, illuminates a tiny spot on a flat bed of fine powder or resin. The energy melts that spot, and an entire layer is eventually traced by the laser. More material is applied and the process repeats.

The problem is that in order to achieve prints with optimally formed internal microstructures one has to engage highly precise control over all elements of the printing process, including ambient temperature, oxygen percentage, powder quality, and laser illumination. It’s easy to produce 3D prints that are inferior in strength to those manufactured with conventional making processes, so this is a significant barrier to 3D printing adoption.

As a result many 3D printer manufacturers have spent considerable time and effort to refine their PBF and SLA process to ensure the best quality 3D print. However, there’s always room for improvement, and that’s just what the holographic research might do.

3D Laser 3D Printing

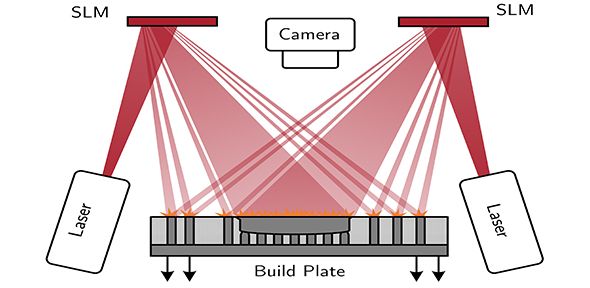

The holographic method allows for far better control of the illumination. UC explains:

“However, computer-generated holograms can help bring the distribution of this energy under control in three dimensions rather than two, as a result of optical diffraction (the bending of light waves around an obstacle). The melt process can then be monitored in real time and the hologram can be recalculated in order to control the shape, quality and material of the AM process.”

This overcomes the issue of variances in the material that cause inconsistent solidification. In theory this can be monitored and controlled, and that could mean, for example, much stronger metal 3D prints. This approach would also work for polymer PBF and SLA systems.

All-Layer PBF?

There’s another very dramatic possibility with this new form of laser illumination: simultaneous production of an entire layer at once. Team member and Ultra Precision Engineering PhD student Peter Christopher explains:

“The aim is to melt an entire layer of metal powder simultaneously, thereby improving the speed of manufacture, as well as removing many of the thermal-related issues experienced in current approaches.”

If I understand this correctly, it means the holographic technique could potentially create a light field corresponding to the necessary illumination for an entire PBF layer, for both metal and polymer environments. If sufficient energy reaches each pixel of the print surface, this could mean an extremely significant increase in PBF print speeds, which are among the slowest in the world of 3D printing.

Of course, this is mere research at this point, but I believe the potential is massive and thus we may see this type of laser system appear in commercial 3D printers of the future.