AddiFab has again deepened its relationship with Mitsubishi Chemical Advanced Materials, this time in a strategic partnership to bring Freeform Injection Molding contract services in three locations.

AddiFab, which emerged on the scene last spring with its interesting Freeform Injection Molding (FIM) technology, has been impressing ever since with the bringing together of 3D printing and injection molding. The process allows for the speed and design complexity of 3D printing and the strength and materials freedoms of traditional injection molding. Since its introduction, it’s been proving out its use with both polymer and metal materials — and with speeding the introduction of another personal protective equipment (PPE) option during the COVID-19 pandemic.

“AddiFab has built Freeform Injection Molding to break key injection molding constraints. FIM lets the injection molder create injection-molded objects with the same design freedom offered by conventional 3D-printing. At the same time, we have brought 3D-printing lead-times and start-up costs to the injection molding industry, without compromising on the choice of materials,” Lasse Staal, AddiFab CEO, said.

Since its initial introduction, AddiFab has had an important relationship with Mitsubishi Chemical. The teams exhibited together at RAPID + TCT 2019, and last fall Mitsubishi Chemical’s venture capital arm invested in AddiFab as the relationship deepened, strengthening the market position of FIM.

Today, AddiFab has announced a strategic partnership with Mitsubishi Chemical Advanced Materials (MCAM) that centers around service availability.

AddiFab x MCAM

Three MCAM locations on three continents will begin offering FIM contract manufacturing services this year.

The companies refer to this strategic partnership as “the natural next step” in their collaboration, as it demonstrates “the commitment of the parties to lead the field of high-end low-volume manufacturing.”

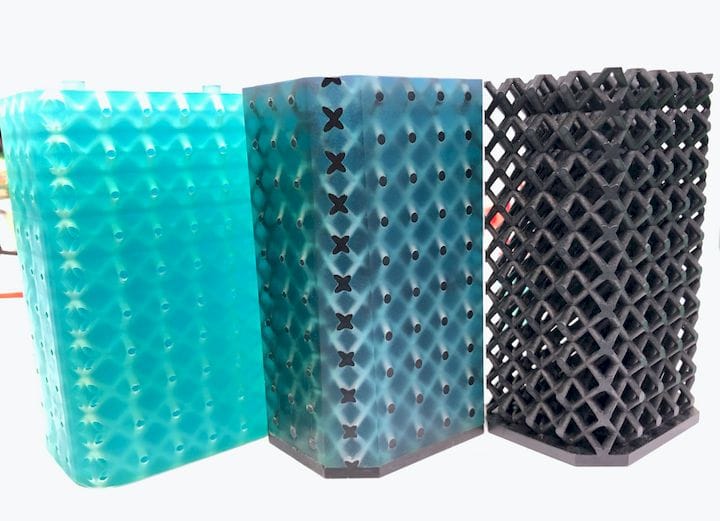

“Mitsubishi Chemical Advanced Materials is leading the field of metal replacement polymers. We quickly realized that Freeform Injection Molding would allow us to offer entirely new levels of light-weighting, and we have been working with AddiFab to bring our KyronMAX materials onto the FIM platform. When we were able to drive an 8,000-pound pick-up truck onto a KyronMAX lattice weighing only 70 grams, we knew we were onto something,” said MCAM Chief Innovations Officer Randy White.

That type of strength has been on display since FIM’s emergence from stealth; at my first in-person meeting with AddiFab at last year’s RAPID + TCT event, AddiFab Inc. Carsten Jarfelt, CEO of US-based AddiFab Inc. (AddiFab ApS is based in Denmark), demonstrated a similar strength test. Of course, that was simply him standing on a small lattice — the 8,000-pound truck goes rather further in proving out the strength of these structures.

MCAM will be bringing FIM service to “select customers” starting early in Q3 this year in Mesa, Arizona. Later this year, facilities in Tielt, Belgium and Nagoya, Japan will also offer this FIM contract manufacturing service.

“At AddiFab, we are thrilled to be teaming up with the world’s NO. 1 in metal replacement materials,” said Staal. “We look forward to working with MCAM on adding entirely new dimensions to the fields of generative design and topology optimization, and to redefining the way metal replacement materials are used in weight reductions.

Also released today is AddiFab’s revamped website — well worth checking out along with the soon-to-come new services.

Via AddiFab