I’m taking a quick look at Gen3D, a CAD tool for generating complex structures.

The company, based in Bath, UK, quite near where the RepRap project began two years ago and now has a Windows-based option, is eponymously named “Gen3D” for generating 3D structures in CAD.

The design concepts used by Gen3D seem a little different from some other paradigms I’ve seen, where 3D structures can literally “evolve” from nothing into complex and utterly unrecognizable yet function shapes. Gen3D is not like that at all, and seems to employ more of a “short cut” paradigm.

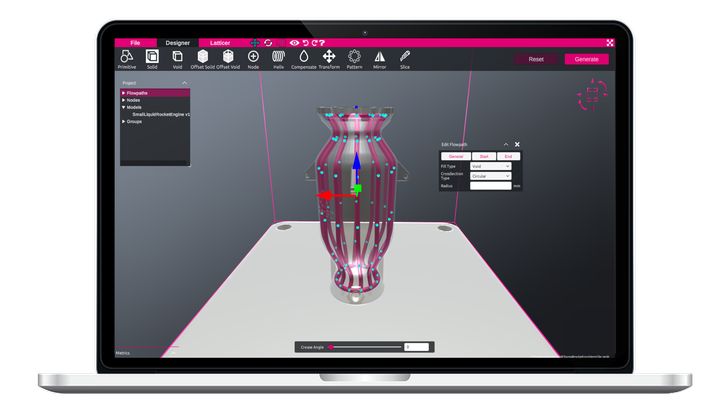

Gen3D Flowpaths

Gen3D frequently uses the concept of “Flowpaths”. These are automatically generated structures between two or more points within a 3D design. For example, if you need a conduit between two surfaces, you start by defining a series of nodes in 3D space representing the end points of the conduit.

Once defined, the nodes can be used to create a “Flowpath” between them. This structure can then be modified in a number of different ways. For example, you can change the diameter of the tube, or change it to a rectangular extrusion, etc.

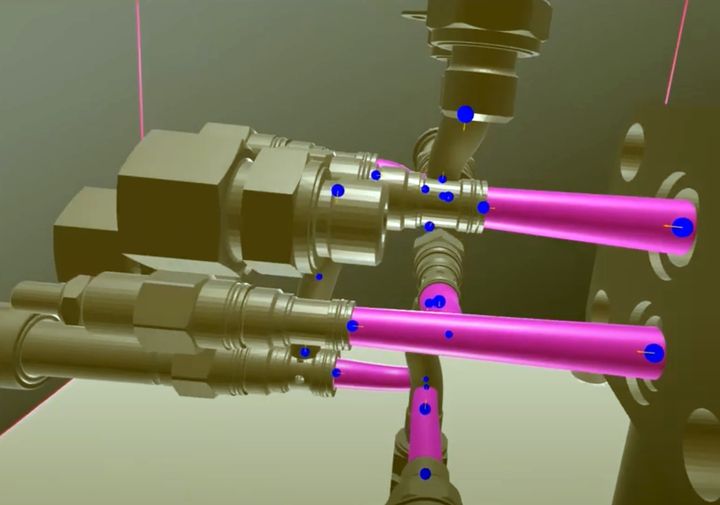

The idea is to enable easy re-engineering of older parts for 3D printing. This is done by defining Flowpath points for the inputs and outputs of a system. Here we can see how this works to re-engineer the design of a hydraulic manifold:

This sounds straightforward, and it is. It’s a remarkably simple paradigm that’s easy to learn, yet it can very rapidly generate highly complex structures that are usually makable only by 3D printing tech. I suppose it’s somewhat like an advanced version of lofts and extrusions, but easier to use.

Flowpaths can be generated in several different ways. For example, you can have them conform to an existing surface, if you require them to lay alongside a component. You can also generate helical Flowpaths around an object, or circular and rectangular patterns. It’s quite flexible.

In addition to the Flowpath method, Gen3D includes another useful generator functions: Lattices. You can, for example, transform a solid structure into a customized lattice. The lattice parameters are easily input, and the generation occurs quickly. By strategically defining lattices as part of a component, one can significantly reduce the part weight.

Gen3D has published a series of very short videos explaining how this all works. They’re short because it is ridiculously easy to use the features, and that’s a very good sign.

Gen3D Accelerator

While the software certainly generates 3D structures, it’s not “fully generative” in that it completely creates the end design. Instead it is more like a toolbox where you can apply a number of functions to more quickly complete a design in a way you might not have imagined.

Gen3D sometimes refers to the software as a “Design Accelerator”, and I think that term is probably most appropriate, because that’s what it does.

The company offers a 14-day free trial of the software through a quick 50MB download. The software runs on Windows only, and requires at least 8GB RAM and a graphics card to function.

If you’re looking for a straightforward way to easily speed up your design sessions, Gen3D might be something to consider.

Via Gen3D