MakerBot announced a new version of their METHOD series that is specifically designed to 3D print strong carbon fiber parts.

The METHOD series was announced only 17 months ago, but has undergone quite a bit of evolution. The line was most recently upgraded by the addition of the METHOD X, a new version that includes much higher temperatures, enabling use of many more engineering materials.

METHOD Print Quality

I’m quite impressed with the METHOD series, as their design allows for the production of incredibly good parts. In a previous story I described seeing what I thought might have been the most perfect ABS 3D print I’d ever seen.

One reason for the high-quality results is MakerBot’s use of a heated chamber rather than merely heating the print surface as is done in most other devices. This allows for extremely uniform heating and cooling, thus virtually eliminating warps and distortions of the prints.

Another reason for the high-quality prints is the way MakerBot made the METHOD “smart”. This is because the machine includes an incredible 21 internal sensors that are used in real time by the METHOD to dynamically adjust the environment and machine operations to optimum levels.

MakerBot Carbon Fiber

Since the introduction of the METHOD X, MakerBot has been partnering with a number of materials providers to widen the availability of materials, but one material that wasn’t mentioned — until now — has been carbon fiber.

Carbon fiber composite filament has long been used in 3D printers, as the tiny fibers mixed with binding polymer create vastly improved part strength. In some applications, carbon fiber prints can even replace metal equivalents.

The problem, however, is that carbon fiber filament is difficult to 3D print on many machines because it is quite abrasive. While the chopped carbon fiber segments are quite tiny, they are still much harder than most metals. This can cause the hot end to rapidly erode, particularly if made from soft brass material as is commonly done.

To overcome this one must use a hardened nozzle, perhaps of hardened steel or tungsten. As MakerBot did not offer this type of equipment, 3D printing carbon fiber filament on a METHOD of any type was not a thing.

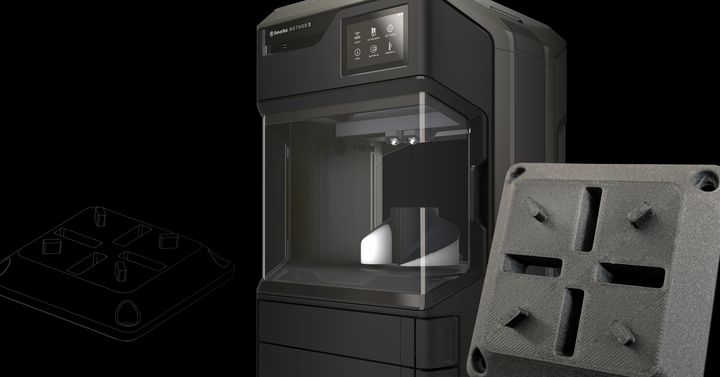

But now it is. MakerBot announced METHOD Carbon Fiber Editions. These are essentially pre-configured variations of the original METHOD and METHOD X devices, specifically for 3D printing carbon fiber filament. They each sport a new smart extruder that indeed has a hardened nozzle capable of withstanding carbon fiber extrusion.

MakerBot’s software has also been configured to enable immediate use of the carbon fiber material on these machines. I should say both METHOD machines will also include a second extruder in which one can use either PVA soluble support material, or, in the case of the METHOD X Carbon Fiber Edition, Stratasys’ SR-30 soluble support.

METHOD Carbon Fiber Print Quality

As I mentioned above, the METHOD X machine has produced the best ABS prints I’ve yet seen, and I wondered if the METHOD Carbon Fiber Editions would be similar. Apparently this is the case, as MakerBot CEO Nadav Goshen told me:

“They are the best looking parts I ever saw on METHOD!”

Part of this is due to the aforementioned quality features but it’s also because the carbon fiber material tends to visually hide layer lines, especially on vertical surfaces. Indeed, they are some great looking prints.

I asked Goshen why move to carbon fiber, and he explained the company is targeting manufacturing, specifically for the production of strong jigs and fixtures.

Goshen explained that in a manufacturing scenario, jigs and fixtures often must require significant strength because they are put under repeated mechanical stress, and that carbon fiber material is a very suitable option for that type of application.

With this offer, a manufacturing company can simply purchase a METHOD Carbon Fiber Edition and place it on the workshop floor, ready to 3D print very strong jigs on demand.

I asked whether the Carbon Fiber Editions are truly new machines or simply just METHODs with a different smart extruder. Goshen explained that technically they are METHODs with a new carbon fiber-capable extruder, the “Composite Extruder”, but there is an important reason for the configuration as offered by MakerBot.

It seems that many companies require just the carbon fiber capability, and may have little interest in other materials. This option allows them to buy a machine that immediately can 3D print parts in their desired material: carbon fiber reinforced polymer. It also ensures the lowest possible price, as buyers don’t have to pay for material capability they don’t need.

Of course, these machines could be modified later to 3D print other materials by simply swapping in one of the other MakerBot METHOD extruders, of which there are now several to choose from.

MakerBot also intends on marketing additional composite materials in the future that would also work with the new Composite Extruder. I have no idea which materials they will release next, but a good guess might be a glass-reinforced nylon material.

MakerBot METHOD Marketing

It seems that MakerBot has an interesting and perhaps sneaky strategy here: get equipment into an organization by leading with carbon fiber. This material would have specific and immediate demand by some organizations.

But once the equipment is in place, those in the customer sites who are championing the use of 3D printing can then very easily demonstrate other uses by using other MakerBot smart extruders. While providing a carbon fiber capability, it may be that MakerBot is also creating a marketing opportunity, too.

The MakerBot Carbon Fiber Editions are available now, and the price is also a surprise: US$3,499 for the introductory offer, which rises to US$4,999 later on. Existing METHOD users are able to upgrade to carbon fiber capability by adding the new Composite Extruder for US$349, and MakerBot is selling carbon fiber filament in 500g spools for US$99.

Via MakerBot