Boom Supersonic’s new XB-1 prototype aircraft turns out to be using plenty of 3D printed parts.

“Boom” was founded a few years ago with the goal of developing and flying the first privately designed supersonic jet. They want to fill the gap left when the famous Concorde left service in 2003, and provide a means for anyone to fly at unbelievable speeds to points around the globe.

This is, as you might suspect, an incredibly ambitious project. The Boom team has to do something no private company has ever done before, and it’s not easy.

At the speeds they intend to hit, the aircraft will undergo stresses and temperatures gradients not seen on slower aircraft. These factors have dramatic effects on the materials and components used in the vehicle.

As a result, Boom must employ a very advanced program to achieve these goals. They are therefore using advanced materials, processes, designs and software to develop “Overture”, their first supersonic passenger jet.

XB-1 Program

However, there are so many advanced aspects of the design they are not building the Overture first; instead they are developing a prototype experimental aircraft, the XB-1, to test out the new technologies they’ve been using.

The XB-1 is a single seat aircraft that is designed to go supersonic, and uses three massive jet engines. The majority of the XB-1 is made from molded carbon fiber parts, which are strong and lightweight and able to withstand the extreme heating without distorting their geometry. This is quite unlike previous supersonic aircraft, like the SR-71, which actually leaked fuel until it could get up to speed, warming up and expanding the frame to close the gaps.

Boom hasn’t flown the XB-1 yet, but they have just “rolled it out” and revealed it to the world. At some later date in 2021 they will attempt the first flight, and that will be done by their team of test pilots. Learnings from the XB-1 flights will be incorporated into the future Overture design.

XB-1 3D Printing

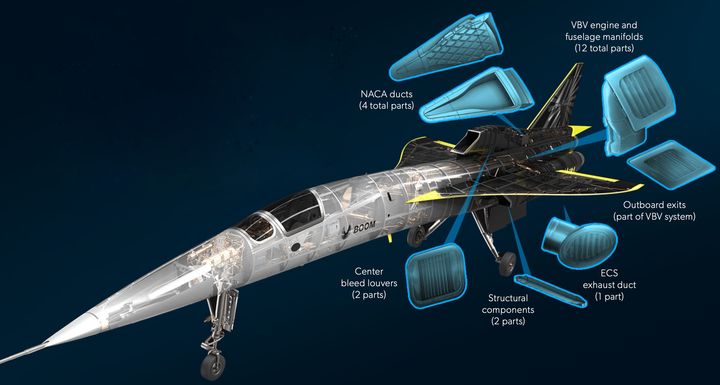

Aside from the massive amount of molded carbon fiber parts in the XB-1, it turns out there are a considerable amount of 3D printed parts as well.

In Boom’s introductory video they spend time explaining the benefits of their relationship with Stratasys, whose equipment helped them not only produce some parts for the aircraft, but also jigs and fixtures used in the assembly of the vehicle.

Boom says with the 3D printers they are able to design and prototype parts right in the workshop. For some, they can even make production end-use parts as well.

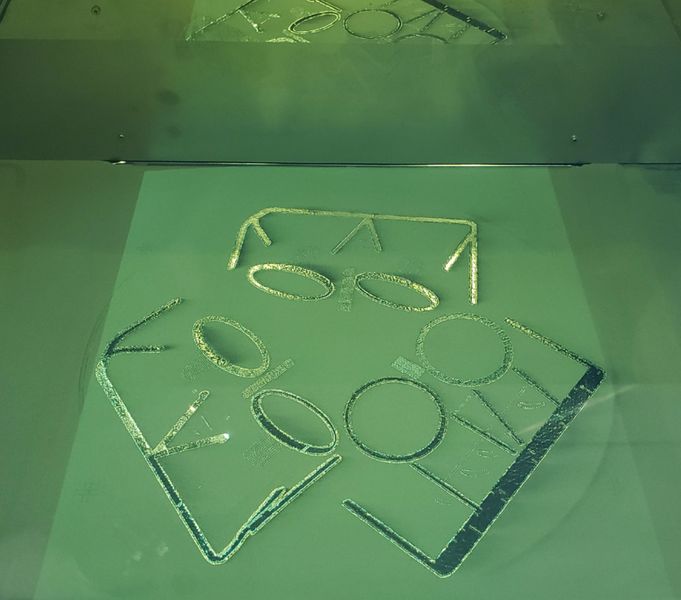

Boom has also been using VELO3D’s Sapphire metal 3D printing technology to produce complex metal parts used in various portions of the vehicle. According to VELO3D, many of the parts were used to help redirect airflow and thus required very precise and complex geometries that would likely be challenging to 3D print.

However, they say:

“In almost every case, the Sapphire was able to print parts directly from Boom’s CAD data, preserving original design intent.”

Additionally, the Sapphire’s very high print quality permitted Boom to use many of the parts without any further surface post-processing; they were already smooth enough for the application right out of the machine. The Sapphire’s ability to 3D print most parts without support structures also contributed to the success as this allowed for production of complex parts without the need for much post-processing.

These parts were carefully designed to provide the necessary function, but at the same time do so with a minimum weight. This is done by making them hollow. VELO3D explains:

“The high aspect ratio (height to width) made possible by the VELO3D machine’s non-contact recoater system (which distributes each new layer of powdered metal to be fused by dual lasers) was another plus. In order to remove mass, the vanes on the center inlet’s bleed louvers were printed hollow, and the parts were designed with high aspect ratios (very thin walls along long spans).”

These parts were 3D printed in titanium material, which by itself is quite lightweight, and made even more-so through 3D printable designs.

Boom is making one of the most advanced aircraft, and to do so they are using the most advanced making technologies, successfully so far.

Via Boom Supersonic and VELO3D