During times of uncertainty, Michigan Tech’s Open Sustainability Technology (MOST) Lab doles out three new open source tools in response to the ongoing pandemic.

The MOST Lab

With advancements in technologies like 3D printing, people can share their designs with people across the world from them in a way that allows them to replicate medical-grade devices without having to face the substantial costs of importation.

The MOST Lab, led by Joshua Pearce (who also is the Richard Witte Endowed Professor of Materials Science and Engineering and a professor of electrical and computer engineering), didn’t make their designs open source by accident. In fact, they published them in a special edition of HardwareX dedicated solely to COVID-19-related technology. The team had put out a call for papers back in March to develop open source medical hardware to help in the pandemic.

With these projects’ introductions last month, Pearce explains that:

“The nature of these designs is such that desired features are relatively easy to add with the test using protocols and parametric design files provided.”

He continues this statement:

“Our hope is that such devices can be built upon by others to achieve full regulatory approval in all countries to ensure humanity is prepared for the next pandemic.”

When the team initially pursued this line of innovation, there was a severe imbalance between the supply and demand of personal protective equipment (PPE), what with most PPE being single-use. Hence, their goals were to create a printer that could make reusable PPE (such as face masks), respiratory equipment that could be custom designed for individual firefighter needs, and an inexpensive design for an inexpensive design for their own 3D printer.

The Cerberus

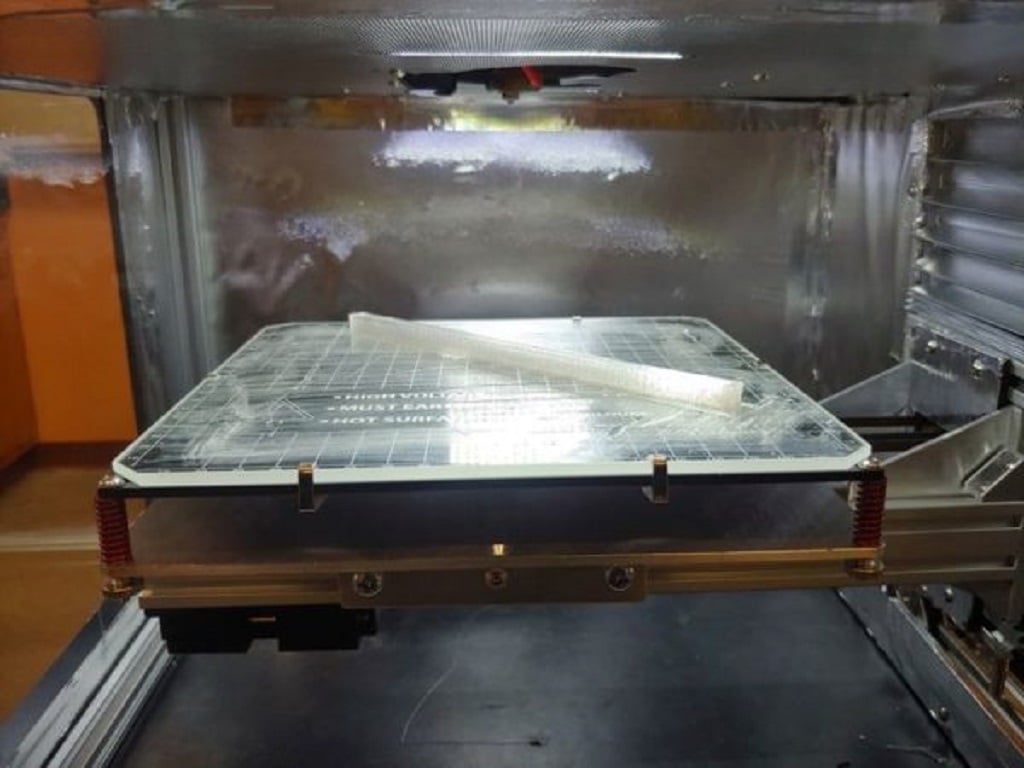

The high-temperature 3D printer Cerberus (presumably named after the mythological three-headed monstrous watchdog of the underworld) features a “three-headed, self-replicating rapid prototyper (RepRap)”. It also possesses a heated bed capable of 200 degrees Celsius and a hot end capable of 500 degrees. The printer contains an isolated heated chamber with a 1 kilowatt space heater core with mains voltage chamber and bed heating for rapid start. It prints PEKK with a tensile strength of 77.5 MPa and ULTEM with a tensile strength of 80.5 MPa.

Most importantly, the Cerberus is an open source printer that can be built for less than $1,000.

Kerry wrote an article specifically focusing on this open source high-temperature 3D printer. This less costly and open source alternative could compete with more expensive 3D printers on the market.

An additional advantage is that because Cerberus can print high-temperature-resistant materials, hospitals can print equipment that can easily be sterilized and reused, which could be a game-changer in today’s pandemic.

PAPR For Firefighters

The PAPR is a powered air-purifying particulate respirator and is made primarily for the benefit of firefighters. It has a controllable airflow and its design allows users to be able to breathe, even if the fan is disconnected or if the battery dies — which in my opinion is the most ingenious part of this design, as I haven’t seen anything quite as tangible in prior proposals.

This design is also open source and can be both printed and assembled using easily accessible components for a mere $150.

Interestingly, the design can replace commercial conversion kits to save 85% or proprietary PAPRs to save over 90% of costs. Its standard design enables easy modifications to other core components and the PAPR can be custom fit to be compatible with firefighter equipment or suspenders. As for complying with national health standards, the PAPR meets the airflow requirements for the National Institute for Occupational Safety and Health (NIOSH) for a whopping 4 hours, which is about 300% over the expected regular use.

The Emergency-Use Ventilator

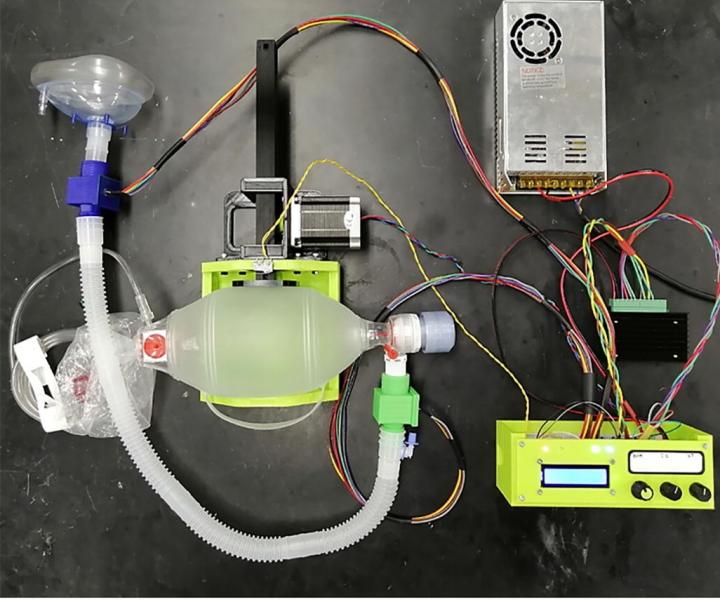

MTU’s final open source creation — a ventilator — could not have come at a better time. With constant shortages of both PPE and hospital equipment (like ventilators), their design shows great promise for immediate application.

Their ventilator can be 3D printed for under $170 and is a resuscitation system that’s based on an open source Arduino controller with a 3D printable parametric component-based structure. The system offers a controlled breathing mode with tidal volumes ranging from 100 to 800 millimeters and breathing rates ranging from 5 to 40 breaths a minute (and an inspiratory to expiratory ratio from 1:1 to 1:4). The system was designed prioritizing reliability and the scalability of measurement circuits through the use of the serial peripheral interface and is able to connect additional hardware because of the object-oriented algorithmic approach of its design.

Experimental results on their prototype (after testing it on an artificial lung for peak inspiratory pressure, respiratory rate, positive end-expiratory pressure, tidal volume, proximal pressure, and lung pressure) reinforce repeatability and accuracy that exceed human capabilities in BVM-based manual ventilation.