News this week sees two companies offering different ways to acquire their 3D printer products.

BigRep and Anisoprint both announced methods of acquisition that differ from the typical “buy a machine” approach that has been standard among most vendors.

BigRep Leasing Program

Berlin-based BigRep announced a new leasing program. They say:

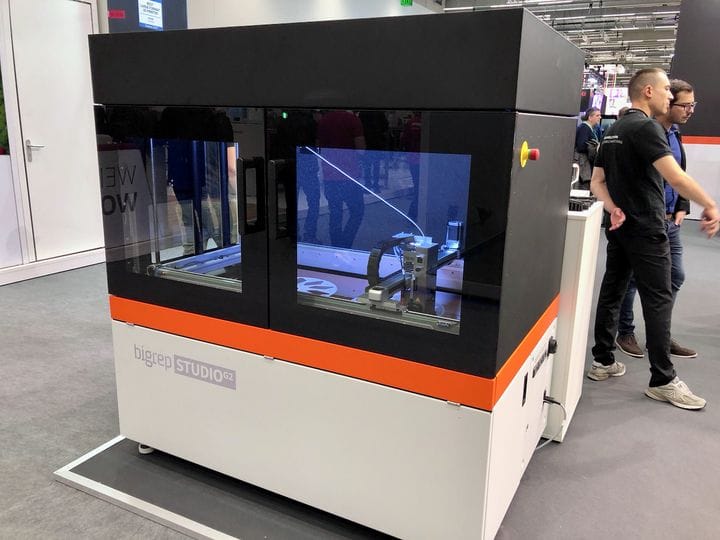

“BigRep, the global leader in large-format additive manufacturing (AM) technology and solutions, is introducing a 3D printer leasing service of their large-format industrial 3D printer (FFF segment). Available today to customers across North America, the innovative turnkey solution offers the BigRep STUDIO G2 industrial 3D printer, the company’s versatile 3D printer for industrial applications. Available in six-month rental leases at an affordable rate, in addition to installation, training and other service features.”

BigRep America President Frank Marangell said:

“For the first time, our service makes a large-format industrial 3D printer available to new customers or small- to mid-sized businesses looking for a hassle-free and flexible turnkey AM solution at an affordable rate.”

Some who normally purchase devices may find this development minor, but it is actually quite important. Leasing is a method of acquiring a device that spreads the cash flow over a fixed period of time, instead of having to put out the entire value all at once. For many businesses, particularly smaller businesses, cash flow is a critical management item, and anything that can be done to “smooth it out” is highly desirable.

Some companies may appear to be “rich”, but internally departments will have budgets that can specify the amount of capital (i.e., one-time spend) that can take place in a year. If that limitation is less than required for purchasing a 3D printer in the usual manner, then there’s no sale taking place.

With leasing, there is no huge capital item appearing in the department’s budget. Instead a small — but regular — lease payment appears each month. In many companies this is the only way to acquire large machines.

Introducing a leasing program opens the door for BigRep to deliver equipment to far more companies in this situation. While any company could make arrangements on their own for loans or third party leases, that’s usually done by the finance department, not the buying department — and they aren’t usually creating new loans. It’s far easier to obtain the financing through the vendor, which in this case will now be BigRep.

Desktop Anisoprinting

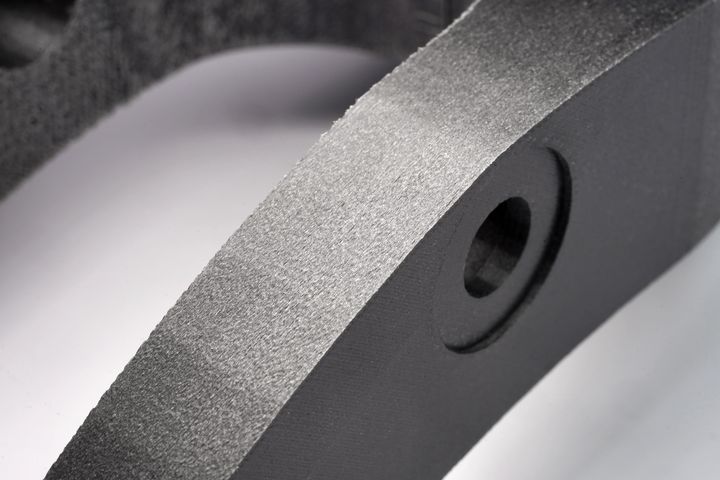

Anisoprint is one of the few 3D printer manufacturers producing equipment that can 3D print objects that include continuous carbon fiber. This makes for incredibly strong parts that can be produced on demand.

But getting the most out of this equipment requires some different skills than are typical for other more common 3D printers. The choice of how to lay down carbon fiber, for example, is something other machine operators don’t have to deal with. Similarly, achieving the part strength also requires balancing the amount of carbon fiber with a suitable proportion of strong thermoplastic material. Again, something not a lot of folks necessarily know about.

To take buyers more easily into that world, Anisoprint has introduced a bundle they call “Desktop Anisoprinting”.

It’s a combination of not only the hardware, but also specific materials, print profiles, and training courses.

Evidently Anisoprint has worked with noted 3D print materials producer Polymaker to develop custom materials that are optimized for use in continuous carbon fiber 3D printing. They say:

”Two plastics, the CFC PA and the Smooth PA, were formulated and fine-tuned specially for Desktop Anisoprinting users by Polymaker — a team of polymer experts, that provide best in the class 3D printing materials.

Anisoprinting is based on its proprietary Composite Fiber Co-extrusion (CFC) technology. It implies a combination of preliminary impregnated and cured fiber with plastic during the printing to get a composite. Thus, The CFC PA is made for better composite material mechanics and perfect adhesion to the reinforcing fiber.

The other plastic is used for external shells of the part. The Smooth PA based on carbon fiber filled polyamide was specially formulated to give a perfect surface quality, with no drying required to print.”

Making 3D Printing Easy

Both of these moves are significant, in that they help new buyers more easily get productive. 3D printing can be hard, either from a financial or technical viewpoint. BigRep and Anisoprint are trying to reduce those barriers to machine use in their own way, and that’s a good thing for everyone.

Via BigRep and Anisoprint