I just finished reading a fascinating interview with Scott Crump, one of the earliest pioneers of 3D printing, and the inventor of the extrusion process.

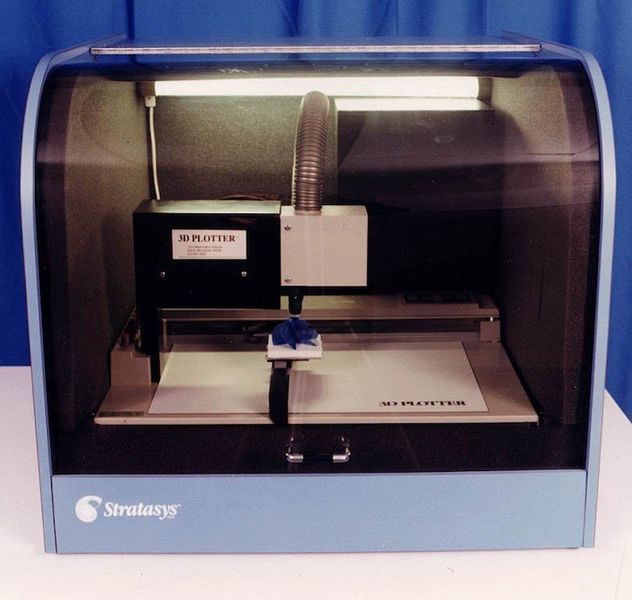

The long interview, published on TCT Magazine, relates a multi-hour conversation between TCT’s Sam Davies and Crump, who recently “retired” from Stratasys, the company he founded years ago after developing FDM 3D printing in his kitchen. From a rough start, the company began to grow and today it is one of the biggest companies in the space, offering products in a number of areas. They’ve grown by acquisition as well, scooping up several notable 3D print companies, including GrabCAD and MakerBot.

Last week it was announced that Crump was stepping down from active duty at Stratasys. However, it’s expected he’s still going to be visible at events as he as done so often in the past. TCT says:

“Crump described his career in the 3D printing industry as a ‘fantastic ride’ but felt now was the right time to step away from Stratasys with the company ‘in good hands’ and Crump himself ready to ‘focus on other things in my personal life.’”

Crump is an incredibly friendly character, and I’ve had the pleasure of meeting him several times. As a result of those interactions, I’ve come to understand his story, and the story of Stratasys.

However, it seems I didn’t know everything, as the TCT interview revealed some things I was unaware of. Here’s what I learned from the interview:

Necessity Is The Mother Of Invention

Many of today’s 3D printer manufacturing companies came about because their founders were dissatisfied with the performance of the 3D printers they were using. They felt they could build something better, and often did. That seems to be the standard pattern for the development of devices in the space.

But it turns out this was the same for Stratasys, even though there were NO 3D printers in existence at the time. Crump had been working for a product development firm that lost a great deal of business opportunity when their prototyping steps took far too long. This bothered him and triggered his interest in developing a machine that could perform “rapid prototyping”.

That machine ultimately became the first 3D printer using the extrusion process, now known as FDM (if Stratasys uses it) and FFF (when others use it).

This is a lesson for us all: when there is a need, try to fill it. Sometimes the solution can be wildly successful.

Why Stratasys Was One of the Few Publicly Traded 3D Printing Companies

When I started in 3D printing way back in 2007 there were only two publicly traded 3D printing companies: Stratasys and 3D Systems. I always wondered why that was the case, when most other companies in the space since that time have consistently remained private.

It turns out that in its early days Stratasys had funding challenges. They sought investment from angels and VCs, but in all cases they were turned down. I’m actually not surprised by this, because even in the best of times it’s difficult to convince an investor of the success prospects for a new venture. But imagine doing that in the 1980s, trying to explain 3D printing — something that did not exist in ANY form at the time. Even the term “3D printing” did not exist!

As a last resort, Stratasys decided to offer shares to the public, and they succeeded. This move netted them millions of dollars from which they built the company we see today.

3D Print Materials Always Mattered

Crump explained that Stratasys’ sales didn’t really take off until they introduced the capability to 3D print in a robust material, ABS. He told TCT:

“We had to have a stronger basic material. We did a lot of research and came up with one that’s our biggest one today and best one, certainly for prototyping, ABS. And when we got those in, we started to get multiple orders from some of them, and really good referrals. But that took a long time. That was the longest beta we’ve ever had.”

In other words, a new material unlocked access to a broad new market. This phenomenon is still occurring today, as companies introduce advanced 3D printing materials, such as high-temperature filaments or carbon fiber-reinforced materials.

The Separation Between MakerBot and Stratasys

When Stratasys acquired MakerBot it was not totally clear why they did so. At the time it was the peak of the “consumer 3D printing era”, where many mistakenly thought that consumers would have a 3D printer in every room of their house. That didn’t happen, but many believed Stratasys bought into that concept and that’s what caused them to buy MakerBot.

That was not the case. Instead it turns out that Stratasys bought MakerBot because they were simply “different”. Crump explains to TCT:

“We felt that, to expand our existing business with awareness, but also expand into applications we just didn’t know about, because we didn’t have a product selling for $2,000, we [would] acquire, mostly for stock, MakerBot.”

TCT adds:

“What was never lost on other players in the industry, was that Stratasys, to some degree, was buying a business that only existed because of its own founder’s invention. But as Crump and Stratasys viewed it, the acquisition was made primarily because of the differences of the two companies, though since MakerBot’s reputation among the consumer market has never fully recovered in light of its decision to go closed source, their similarities have been useful in steering the company as a more professional-focused machine provider.”

Consumer 3D Printing Will Eventually Arrive

Finally, the interview quoted Crump saying:

“On one hand, it [the MakerBot acquisition] brought mainstream world media attention to the industry which we could never do – we did a good job, but we had a limited budget – but it also brought, in hindsight, false expectations in certain segments, namely in the consumer segment, but that will come, other things have to line up, and brought real expectations within our commercial, industrial [segments]. Since then, the industry has grown in its own natural pace and continuing to broaden the applications in a wide range of industries. And since then, the media and broader market have gained a bit better of an understanding of what the technology can do and can’t do and, importantly, began to harness the truly transformational benefits of the technology.”

Did you catch that? Crump believes that the consumer segment “will come”, if certain things “line up”.

I believe that too.

If you’re into 3D print history, I strongly encourage you to take a read of the TCT interview, where you’ll also find some fascinating images of early technologies.

Via TCT Magazine