Charles R. Goulding and Preeti Sulibhavi consider some of the homey and 3D printed touches possible with IKEA furniture and accessories.

IKEA helps consumers design their life at home. That is what their ultimate aim is, whether it is living room furniture or a home office table and desk system. IKEA brands itself as offering simple solutions for everyday furniture and storage needs. It is recognizable for its modernist designs and eco-friendly simplicity. It is also wallet-friendly as IKEA generally has lower prices than its industry competitors.

IKEA is a multinational, Swedish furniture retailer specializing in designing and selling ready-to-assemble furniture, kitchen appliances and home accessories among other home goods as well as occasional home services. It was founded in 1943, but since 2008 has been the world’s largest furniture retailer.

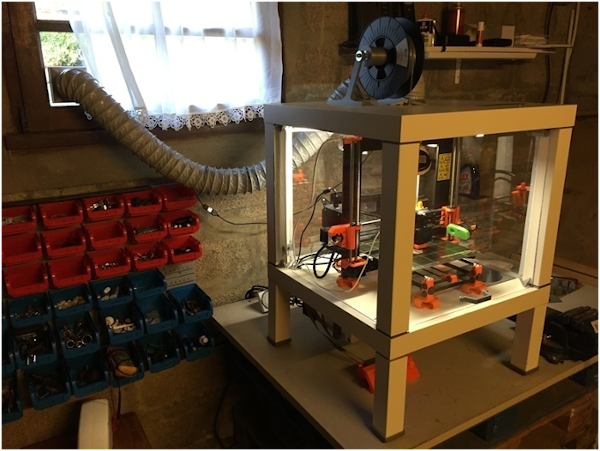

IKEA is continuously adjusting to market conditions with increased e-commerce, new smaller footprint stores and technology that empowers the customer to obtain the solutions they want. This includes 3D printing.

IKEA’s 3D printed add-ons have helped make furniture more accessible and ADA-friendly. IKEA has collaborated with Milbat and UNYQ on “ThisAbles,” a project that provides 3D printed add-ons for furniture that can be difficult to use with certain physical challenges. Included in these items are easier-to-grab handles, mega switches, bumpers to protect cabinets, curtain grippers and lifts to raise couches. Shoppers can even ask for customizations if the designs don’t fit other, third-party furniture.

ThisAbles was launched by IKEA Israel in an effort to make the company’s basic chic designed home furnishings more easily accessible to people with physical challenges. Talk about how we described how the 3D printing industry can also learn what the customer wants by walking around IKEA stores, just as we recommended the 3D printing industry do in our recent home improvement article. For instance, a walk through an IKEA store would demonstrate to anyone that kitchen accessories are almost always highly sought after.

IKEA also offers personalized gaming comfort equipment made possible with 3D printing. Such outfitting can make even sitting much more comfortable.

Research and Development Tax Credits are available for the eligible U.S.-based, 3D printing furniture design activities that IKEA engages in.

The Research and Development Tax Credit

Whether it’s used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Enacted in 1981, the now permanent Federal Research and Development (R&D) Tax Credit allows a credit that typically ranges from 4%-7% of eligible spending for new and improved products and processes. Qualified research must meet the following four criteria:

- Must be technological in nature

- Must be a component of the taxpayer’s business

- Must represent R&D in the experimental sense and generally includes all such costs related to the development or improvement of a product or process

- Must eliminate uncertainty through a process of experimentation that considers one or more alternatives

Eligible costs include US employee wages, cost of supplies consumed in the R&D process, cost of pre-production testing, US contract research expenses, and certain costs associated with developing a patent.

On December 18, 2015, President Obama signed the PATH Act, making the R&D Tax Credit permanent. Beginning in 2016, the R&D credit has been used to offset Alternative Minimum Tax (AMT) for companies with revenue below $50MM and, startup businesses can obtain up to $250,000 per year in payroll tax cash rebates.

Home, Sweet Home

At the end of the day, people would generally like to come back to their homes to feel happy and comfortable. IKEA is helping consumers achieve this and 3D printing can help make home, sweet home.