Cellulose fibres and biodegradable nanoparticles were combined by researchers at ETH Zurich to produce a gel that could pave the path for personalized biomaterial implants.

Personalization

Personalization makes everything better and this situation is no different. Why buy any drug, when you can buy drugs that are customized to the genetic makeup of your body? Likewise, why get any implant, when you could get an implant that’s quite literally made for you? Although personalized implants are a long way off for now, Mark Tibbitt, Professor of Macromolecular Engineering in the Department of Mechanical and Process Engineering at ETH Zurich, says:

“But at the moment, we’re making great progress toward this goal — and learning a lot in the process.”

Initially, researchers of precision biomaterials had to develop new inks for the 3D printer for every application. Tibbitt explains this as:

“If someone wanted to replicate part of an eye, for instance, they weren’t able to draw on the work of people who design auricular prostheses.”

The Ink

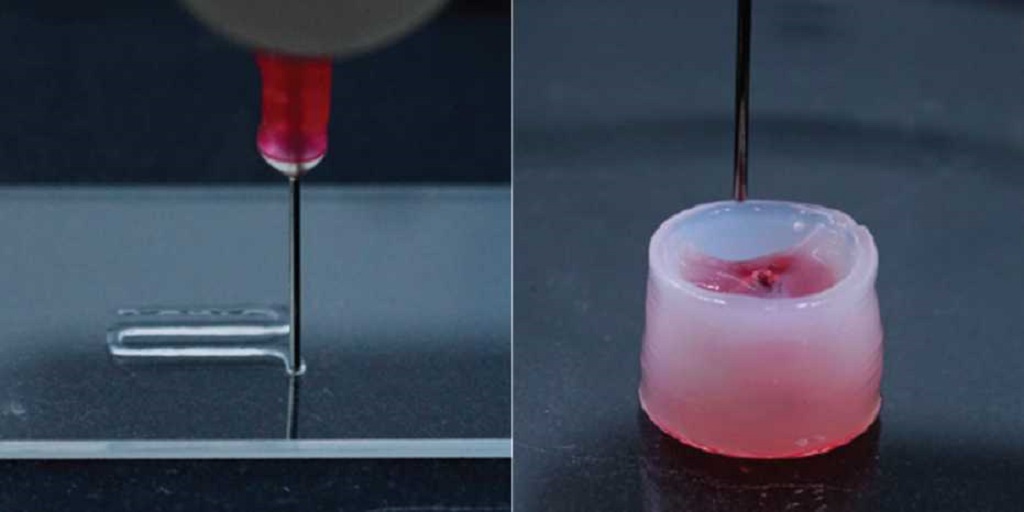

The universal carrier ink created by him and his team, however, “dramatically simplifies” the development of new applications — according to the paper written by these researchers. Your toothpaste can’t be too runny, or it would run off of your paste. Similarly, if it’s too thick, you wouldn’t even be able to get it out of your tube. Hence, 3D printing requires a solution to the “toothpaste problem”, where the carrier ink would need to liquefy to flow through the printing nozzle and then solidify, so that the structure doesn’t immediately lose its shape.

This new carrier ink is made up of cellulose fibres that are dissolved in water and combined with biodegradable polymeric nanoparticles. When there’s no external pressure, the fibres adhere to the particles, creating a transient network. When experiencing high shear forces in the printer nozzle, this network is disturbed (this is where the gel becomes a liquid — briefly). As it exits the nozzle, there is once again no external pressure and the gel reforms to hold the shape of the printed object.

Tibbitt and his team continued their experiments by adding different polymers (like hylauronic acid, gelatine, collage, or fibrinogen) to their completed carrier ink. None of these polymers changed the ink’s flow behaviour through the printer nozzle.

Tibbitt and his team didn’t stop there. They tested the behavior of living cells in their newfound ink and found that the cells survive in the ink in the same numbers as they would outside it. Since hydrophobic substances can be incorporated into the nanoparticles and hydrophilic substances can be added to the aqueous phase along with the cellulose fibres, the researches have proved that their ink is applicable in the development of novel drug delivery systems. The ink has many versatile applications, making it truly “universal”.

Via ETH Zurich