It’s been brought to our attention that there is another freely downloadable design for a high-temperature 3D printer.

Previously we found the Cerberus high-temperature 3D printer design made by a team at Michigan Tech. They decided to open source the design and posted the full set of design files on GitHub for anyone to access, using their open source license.

At the time I believe this was the first fully open source high-temperature 3D printer posted publicly. I think that’s still the case, but there seems to be another option.

DIY High-Temperature 3D Printer

This option was published by igus last year. igus, if you’re not familiar, is a German manufacturer of complex polymers and mechanical components. I see them often at 3D print trade shows (when we had trade shows…) displaying products such as bearings, cable management solutions, linear guides, and much more. Many of their components can be and are used to build 3D printers.

They also provide unusual 3D print materials, such as iglidur, which is a very durable material that resists wear. It’s excellent for 3D printing mechanical components expected to experience frictional forces.

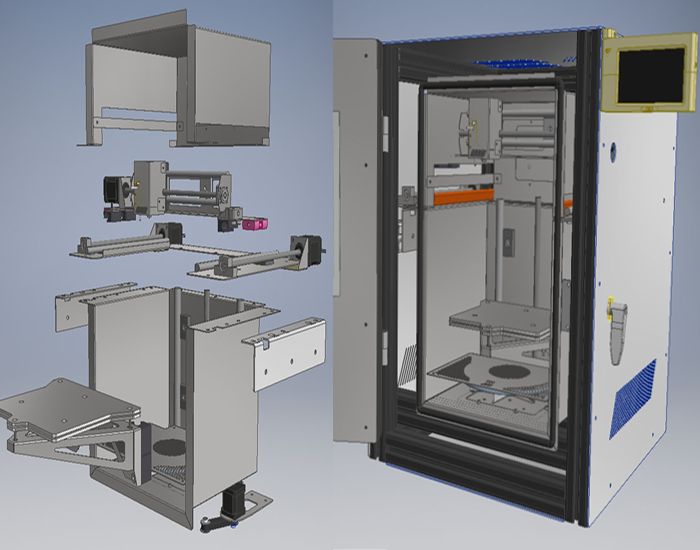

Last year igus published a post describing the design for an unnamed high-temperature 3D printer. In the post, they say:

“A self-built 3D high temperature printer based on drylin W rail guides and dryspin steep-thread spindle made of stainless steel in combination with spindle nuts made of high-temperature resistant iglidur materials.

Low-cost design in the own factory: Based on this idea, the igus team of additive manufacturing has developed and built a high temperature 3D- printer with in-house mechanical engineering components.”

As you might expect, the design makes very heavy use of igus components. This is good, as many of the mechanical components do not require lubrication due to the use of the advanced igus materials.

I don’t have the specifications for this design, but you can see a short video of it in operation here, as it 3D prints an object at 300C:

igus also sells a kit that contains all of the components they supply for this build.

Open Source High-Temperature 3D Printer

To be clear, this is NOT an open source design. The files are only accessible if you register with igus, which suggests that this move is partly a way to increase their contact lists and promote the use of their advanced components.

I suspect this is a pretty decent design, but the fact that it isn’t truly open source will no doubt discourage many from taking it on. Building a high-temperature 3D printer is not the most straightforward task, and it’s quite possible some may wish to tweak the design. That’s not really possible in the way igus has set up this project.

I expect igus may have gotten a larger response to this design if they actually published it under an appropriate open source license. They would have been in a great position to provide full assembly kits for the project, and could have taken advantage of the currently increasing interest in high-temperature 3D printing.

Since there is a competing free design that is actually open source as mentioned above, it’s quite likely anyone seeking a high-temperature 3D printer design will head there first.

Via igus (Hat tip to Benjamin)