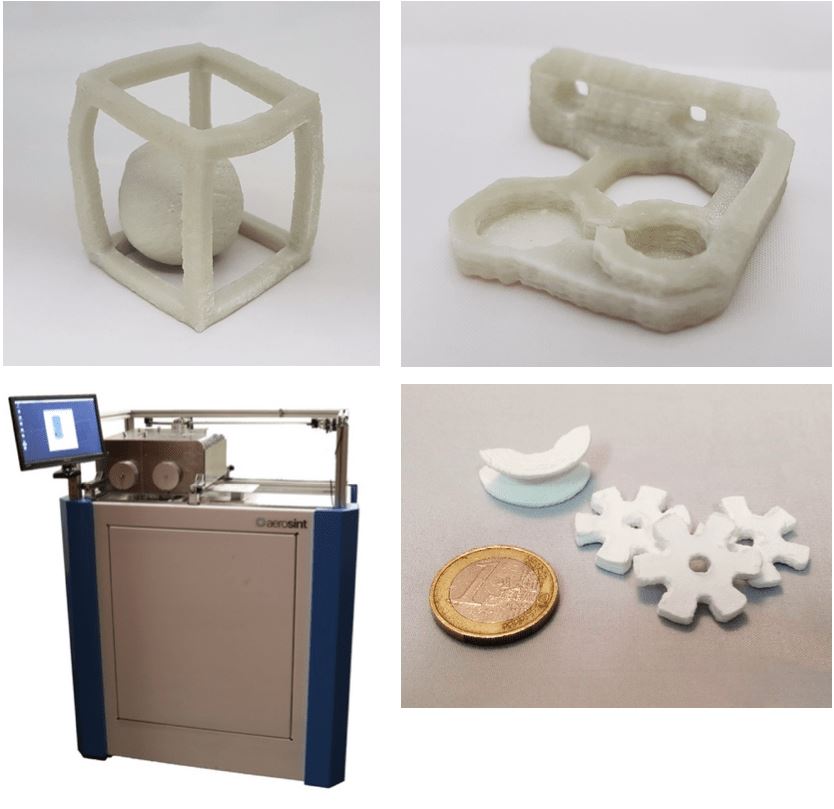

![Example prints and the Aerosint setup. The cube is 5cm to one side, with a strut of 5mm, the bracket is 4.5cm to a side, with a height of 1cm. Both are made of glass. The gears and curved shape are made from Aluminum oxide (us kindly provided to us by Sasol). [Image: Aerosint]](https://fabbaloo.com/wp-content/uploads/2020/05/aerosintceramics1_img_5eb092da1c181.jpg)

Aerosint is taking steps to make ceramic 3D printing more robust with a binder-free powder bed process.

Ceramics are difficult to make — not just to 3D print. The materials are strong, but brittle, and even traditional means of manufacture have a relatively high failure rate in both process and final product. When it comes to 3D printing, we’ve heard of a good many endeavors to work with ceramics — but not nearly so many as with more manageable materials, like polymers and metals.

Enter Aerosint.

The Belgium-based company emerged relatively recently onto the scene — I first met one of their engineers at TCT Show 2017, but much of that chat was embargoed until later that autumn. They introduced an intriguing concept for multi-material powder bed 3D printing that started with polymers, expanded to high-temperature polymers, and also works with multi-metal 3D printing and the first powder bed chemical anti-counterfeiting.

Aerosint engineers have now taken their unique selective powder deposition process to work on another technologically tricky undertaking: 3D printing ceramics. Without binders.

Two of the team’s research engineers, Bram Neirinck and Kevin Eckes, recently shared a look into their work titled “Why selective powder deposition can help ceramic 3D printing reach its full potential.”

They begin with a look into why ceramic manufacture in general, and ceramic 3D printing specifically, has historically faced difficulties. They dig next into the work at Aerosint to address those stopping points and circumvent existing issues — many of which, in additive manufacturing, have to do with use of binders.

We asked for a bit more detail.

“Being able to deposit powder directly into the correct shape without binder means that the sintering process can be greatly simplified and you don’t need additional debinding equipment. Hence it would be easy for a ceramics workshop to include selective powder deposition into their workflow, without needing additional equipment or effort. It also means you can make parts with much more bulky thicker sections, stretching the spectrum of ceramic parts that can be made with AM,” Bram Neirinck, Senior R&D Engineer, Aerosint, tells us.

The Need For New Solutions

But, you may query, metal and ceramics do have some similarities; why do existing sintering technologies work with metal 3D printing but not with ceramic?

SLS 3D printing relies on a localized laser to sinter the powder material into the designed part. The concentrated laser beam means quick temperature changes, and ceramics “tend to be thermal shock sensitive, not liking fast temperature changes,” the Aerosint engineers note in short: “As such they do not lend themselves to localized laser sintering.”

This is when binders tend to come in:

“Instead all current commercial AM technologies for the fabrication of ceramic parts is based on the use of a polymer binder, either polymerized in situ using stereolithography or applied using a jetting / printing, which brings us back to the issue of debinding. Polymers can often be dissolved in organic solvents or burned out, so why are binders problematic? There are two main reasons: part stability and processing time. Burning out binders causes polymers to be decomposed into gases, and at high temperatures gas bubbles trapped within small pores can stress parts to the point of cracking,” Neirinck and Eckes write.

Using a binder to keep materials together during the 3D printing process means that eventually a debinding process takes place. Adding more steps to the process means more potential points of failure, often including cracking when it comes to delicate ceramic materials.

Most ceramic 3D printing to date involves finely featured parts, which are coming along quite well — but remain quite limited in the scope of what can be effectively designed.

Aerosint studied other methods — binder jetting, slurry extrusion, SLA, XJet’s NanoParticle Jetting, Rapidia’s freeform casting process using water-soluble polymer binders — and found progress being made. They also found significant limitations remaining in place, especially when it comes to thicker (they note “in this case ‘thick’ means having a wall thickness of five millimeters or greater; a thickness that in many industrial cases would still be considered quite thin”) parts.

Another Way

So Aerosint looked to their own selective powder deposition technology and, on their first attempt, found some success working in a new way.

“With the Aerosint technology a powderbed can be built containing a predefined three-dimensional shape of technical ceramic powder surrounded by an inert support powder. It stands to reason that if the support powder sinters at a much higher temperature than the shaped build powder, a sintering temperature can be chosen that sinters only the build material together. In this way we might just have a winning solution for making near net ceramic shapes in a manner that more closely resembles the traditional production processes,” Neirinck and Eckes write.

“To explain it in another way, instead of using a mold to cast the particles in the form of a slurry, we deposit the mold together with the ceramic particles we want to sinter. As we do not need to remove water, and we choose a mold material that does not sinter, we can sinter the part directly. No debinding required, just put the entire powder bed into a furnace and start the heating cycle.”

They’ve shared their results quite early on; there remains a lot of work ahead, which they readily admit.

The initial pieces they’ve made, in both glass and alumina, show thick walls. The most obvious initial limitation is relatively low resolution, which also leads to a rougher surface finish.

Neirinck shares with us a bit of a look ahead into where the team will be focusing next efforts:

“I’m working on ways to get the technology even closer to traditional processes, but more on that in the future. I’m currently also getting my hands on more powder types to deposit. At the same time the team is working on improving the deposition resolution so we can also add finer features. This is the biggest challenge at this moment: we cannot deposit features with the same size and resolution as in the SLA based technology. We also need a high temp container to keep our powder deposits in. This limits the size we can currently print somewhat,” he tells us.

“Truly, this kind of results can only be obtained with selective

powder deposition. That is where we keep standing out.”

Via Aerosint

Tritone has been quietly building their MoldJet technology and is nearing a release of their beta 3D printing equipment.