![[Image: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/optomec1a_img_5eb095f4e1628.jpg)

We recently caught up with Optomec for a chat about opportunities in the 3D printing industry.

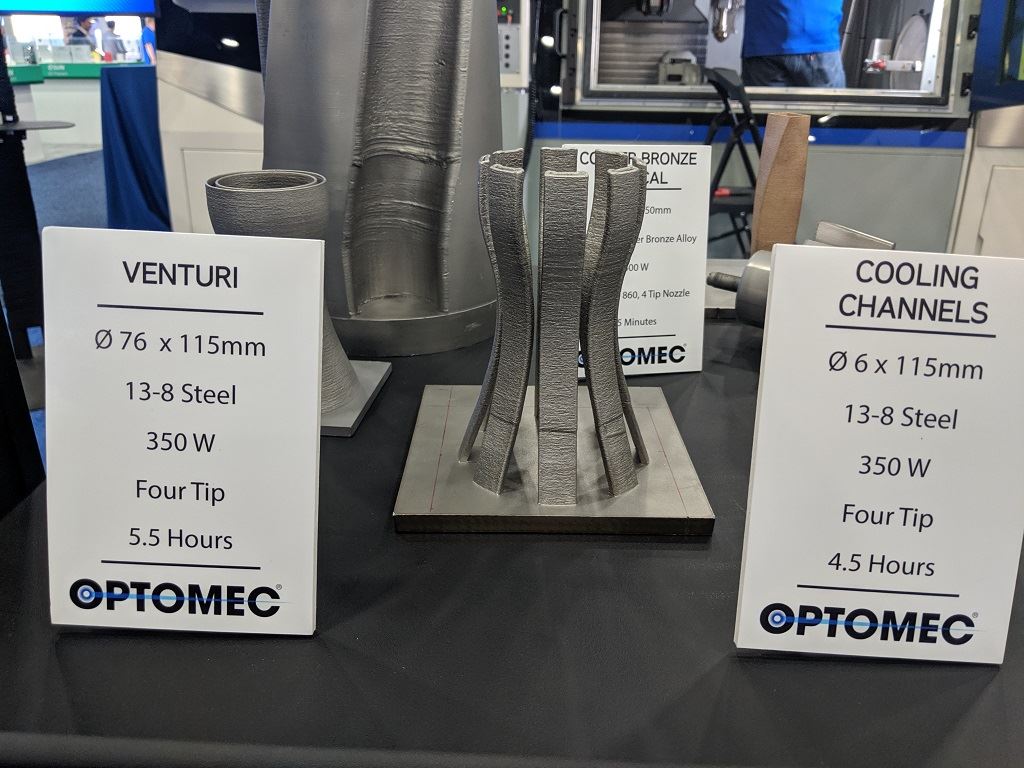

The company is well known for both its electronics (Aerosol Jet) and its metal (LENS) 3D printing capabilities. Over the last year, Marketing Director Mike Dean told me, highlights have included advances in electronics and work with structural metals. We then focused mostly on the latest in LENS, as Optomec was featuring its five-axis motion control system, enabled by SIemens control system.

Opportunities in DED

Late last year, Optomec purchased Huffman, further advancing its metal portfolio — and opening up more opportunity.

“They have a niche focus with gas turbine engine parts,” Dean said of the Huffman acquisition. “They’re very focused capabilities, which can be run by operators, not just engineers. There’s a simplified workflow. The software is a very key piece.”

The DED experience from Huffman — which refers to the system as “laser cladding” — enhances Optomec’s positioning as metal remains a major focus throughout the 3D printing industry.

We are hearing increasingly about expanding applications in spare parts production for a variety of 3D printing technologies, both metal and polymer, but along with those goes something else: repair.

“There’s a lot of interest in repair, which suits DED best,” Dean added. “Customers are interested in going to a digital maintenance warehouse instead of physical.”

DED is well suited indeed to repairs, as an existing metal part with worn away sections can be placed in a build chamber and effectively be rebuilt, negating the need to create an entirely new — and generally quite expensive — part.

“There are a lot of growth opportunities in repairing high-value metals: think oil and gas, with corrosion-resistant parts and repairs,” Dean said.

Optomec had opportunity in mind with its latest offerings. Hybrid capabilities, which tie in machining with additive manufacturing to best meet exacting accuracy marks, are a major highlight. Their 860 Hybrid CA system operates in a sealed chamber with a controlled atmosphere, allowing for work with reactive metals like titanium.

Industry Growth

And the reception? At least at this year’s RAPID + TCT where there were dozens of new product introductions, it was “better than we expected.”

Overall, Optomec remains optimistic about the future of 3D printing — and about their place in the industry. There remains, of course, room for some important growth yet to come, and the company isn’t shying away from these realities.

“The industry needs to standardize terminology. It still needs to build awareness, to put more data out there to give assurance,” Dean said.

For their part, Optomec is ready to continue on its path with increased momentum. They see opportunities to leverage the worldwide distribution network gained through the Huffman acquisition, and continue on their path toward growth.

Via Optomec

Aerosint and Aconity have proven out their work in multi-metal powder deposition 3D printing.