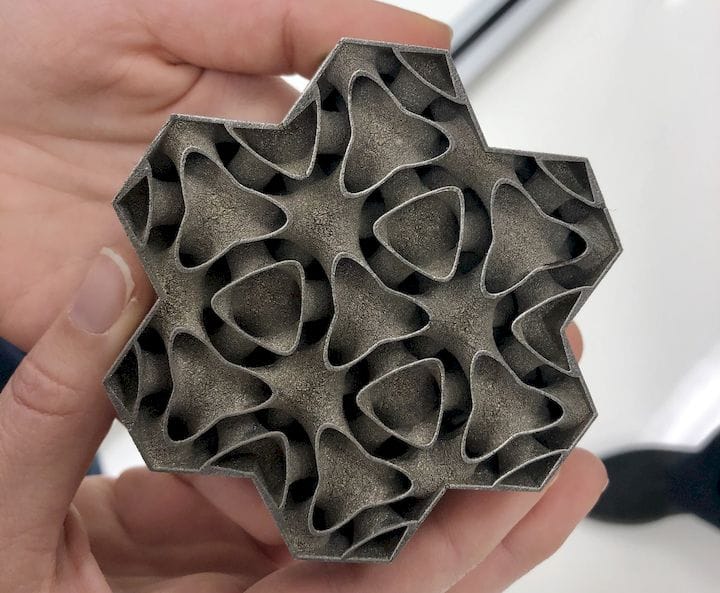

![A 3D printed metal heat exchanger with highly advanced design [Source: GE]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0980cbaa52.jpg)

GE has developed a fascinating 3D printed part design that’s partly inspired by biology.

The new part is a heat exchanger that is eventually intended to be used in gas turbine electrical generation systems. The idea is to capture the otherwise-lost heat created by the primary turbine, and then cycle it through to a secondary turbine. This allows more efficient use of the heat by preventing and reusing traditionally lost heat.

Normally such heat transfers are accomplished by creating and moving steam around the generation plant. However, there is a significant limitation by using steam, because it has a maximum operational temperature of only 650C. If there were a way to transfer higher heat levels, more efficiency could be achieved.

GE accomplished this by substituting CO2 for steam.

Actually, it’s “supercritical” CO2. According to Wikipedia, a supercritical fluid is:

“A supercritical fluid is any substance at a temperature and pressure above its critical point, where distinct liquid and gas phases do not exist. It can effuse through solids like a gas, and dissolve materials like a liquid. In addition, close to the critical point, small changes in pressure or temperature result in large changes in density, allowing many properties of a supercritical fluid to be fine-tuned.”

Basically it’s a way of creating a highly dense substance that has the mechanical properties of a liquid — ideal for transferring heat energy. It also allows for a practical heat level of around 900C, far higher than steam.

Of course, to go along with the hot supercritical fluid, there must be powerful heat exchangers as well. These required unusual designs that were achievable only using 3D printing’s unique ability to freely design any conceivable geometry.

The GE researchers were inspired by biology. They explain:

“The lung accomplishes its heat-exchange function with a network of capillaries, which split the flow of blood into small streams to maximize their exposure to the cooler air coming in from the outside, releasing heat and absorbing oxygen. The GE heat exchanger, designed by scientist Dan Erno, does something similar.

It takes hot airflow that comes out of the gas turbine and splits and recombines it continuously into a trifurcating network of ducts, each less than 2.5 millimeters in diameter, that are interlaced with another network of channels filled with the colder working fluid (in this case, supercritical CO2) that runs in the opposite direction. The hot air and the working fluid are kept physically separate, but their close proximity allows for efficient heat exchange.”

I’ve seen instances of biology inspiring 3D designs for art installations and some in architecture, but there are very few in industry. Could this be due to the methods and training of design staff? It may take examples like this one from GE to inspire others producing 3D printed metal parts that fully leverage the technology.

Via GE Reports

This week’s selection is a 3D printed Coronavirus!