![The 2019 Sculpteo State of 3D Printing report [Source: Sculpteo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0968bca5a0.jpg)

Every year 3D print service Sculpteo issues a report on their users’ activities in 3D printing.

This year the survey is no less enlightening than it has been the previous four years of its existence. Let’s take a look at what they found.

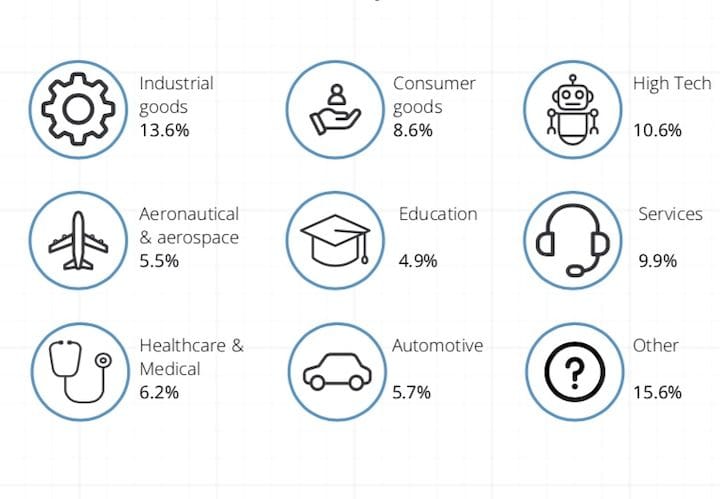

First, however, it is useful to look at the categorization of the survey’s respondents. They had more than 1300 responses, making this perhaps one of the most comprehensive surveys within the 3D printing space. A large 13% of respondents were women, which tracks with our own survey and indicates a rising proportion of women in the industry.

Sculpteo’s report is no doubt a bit skewed towards European views, however, as some 58.7% of respondents were located there, with 20.2% from Asia and only 16.6% from North America. Only 21.8% use 3D printing for casual use, and over 60% use it for “work”.

The respondents not only used 3D printing technology frequently (defined as “at least a few times per month”), but they also have relatively high educational backgrounds, with more than half having “at least a Master’s degree”, mostly in Engineering. This last statistic is quite interesting, and poses some questions about the usability of the technology: if only those with advanced degrees are using it, is there a conceptual or ease-of-use challenge we’re all missing?

As usual, a very popular use for the technology is for prototyping and product development. However, it seems that “Production” is now a major use pattern. In fact, Sculpteo says that over 50% of respondents now use the technology in this way. This tracks with our empirical knowledge on the technology, where we see an increasing number of vendors providing production-style solutions to meet user demand.

By far the biggest challenge to Sculpteo’s respondents when using 3D printing technology is quality control. This is not surprising, given the significant production use: products absolutely must meet quality criteria or they will be rejected.

What’s more interesting is that 20-30% of respondents still find challenges in areas of:

-

Quotations

-

File preparation

-

Machine setup

-

Maintenance

-

Job preparation

I believe this is significant. If that many respondents report problems in these areas, then there is something wrong with the software and workflow tools being used. It may be that respondents are not using the correct tools, as we’ve seen a number of new vendors offering unique solutions that would seem to be powerful.

Of the various 3D printing processes, it seems that only plastic extrusion (“FDM” in Sculpteo’s report) is a technology that is popularly used by respondents in-house. All other 3D printing processes, even SLS and SLA, are mostly performed by service providers. This also hints at a knowledge or ease-of-use gap.

While most companies apparently use CAD design and Simulation tools and services, and a few use 3D Scanning, I am surprised that the number of respondents using Reverse Engineering is the same as any other activity. I’m wondering if this suggests a large proportion of companies are attempting to convert old “paper designed” products into new digital 3D models?

The most popular reason for using 3D printing is the ability to produce complex geometries, which makes a lot of sense: 3D printing is the only technology that can reasonably do so. It also tracks with the notion of increased production use, as very complex objects are more frequently being used in production applications.

Respondents say the “cost of entry” and “knowledge gap” are the biggest barriers to 3D printing technology, and I heartily agree, particularly on that last point, which shows up repeatedly and indirectly through much of the survey results. However, respondents paradoxically rank “more training” as low and “more reliable technologies” as high in things they’d like to see.

Importantly, more than half of the respondents say 3D printing has given them a significant competitive advantage as well as allowing them to gain on competitors. It seems that many users are now properly leveraging the technology in profitable ways. This makes sense because the majority of the respondents have now been using the technology for several years and have had time to mature their use of the technology. Virtually no respondents expected to decrease their use of 3D printing.

Another hint at the maturity of the technology in organizations is that Sculpteo sees a trend of vastly increasing investment amounts in the technology over the five years of this report.

There’s a great deal more detail in this report, and I strongly encourage you to take a look at the well-laid-out survey results from Sculpteo.

Via Sculpteo