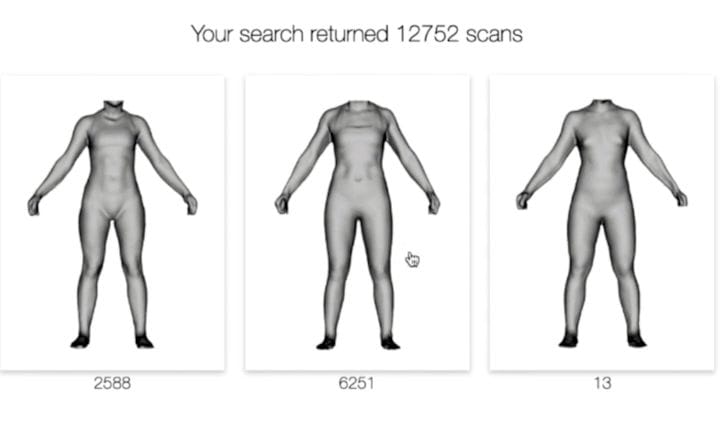

![3D models of human bodies automatically generated by Bodyblock [Source: Bodyblock]](https://fabbaloo.com/wp-content/uploads/2020/05/bodyblock-3d-models_img_5eb096ff8d48c.jpg)

I’m looking at an interesting 3D model service called Bodyblock.

It’s an AI-powered database of body shapes that is hoping to impact the apparel industry in a big way. The problem they hope to solve is the dilemma posed by online fashion shopping: how do you know whether a piece fits or not?

For many online shoppers, the answer is simple: order a number of variations and try them on when they arrive. Then send back the ones that don’t fit, keeping the one that does. I’m sure you’ve heard of people doing this, but it does seem rather wasteful in many respects.

It turns out that it is not only wasteful, but costly for the fashion manufacturers: they lose considerable profit due to these returns, as they sometimes must pay for shipping, and the returned items might not be sold as new anymore. Discounted fashions is not a strategic way to make money.

Bodyblock enters this area with a database of over 1M full 3D body scans. They’ve collected them from a worldwide deployment of their Fit3D body scanners. These are installed in public locations, typically fitness clubs, where participants can monitor their body re-shaping progress.

![The Fit3D body scanner [Source: Fit3D]](https://fabbaloo.com/wp-content/uploads/2020/05/fit3d-body-scanner_img_5eb096ffe63b4.jpg)

But the side effect is that Bodyblock collects these 3D scans and can do other analyses on them.

Using AI techniques, they’ve developed an API that can be used by online fashion sellers. Here’s how it works: a visitor is asked a few easy questions about body measurements. Then their AI system uses these as keys to predict the actual body shape from within their database. Apparently they achieve 96% accuracy with this approach.

The online fashion vendor can then more easily recommend a product that truly fits the wearer. It’s a terrific idea and could likely save the fashion industry billions of dollars in wasted effort each year, not to mention the environmental costs of producing and transporting the fashions.

![Bodyblock generating a likely body 3D shape [Source: Bodyblock]](https://fabbaloo.com/wp-content/uploads/2020/05/bodyblock-service_img_5eb097002b1f7.jpg)

You may be wondering what all this has to do with 3D printing. I realized there could be a very strong connection between Bodyblock and 3D printing: custom fashions.

There has been considerable interest in 3D printed fashions, yet very few general implementations. I believe this is due to a few barriers that need to be broken down:

Cost: Many 3D printed fashions are made with high-end equipment that has very high material costs. These costs make sense for manufacturing, but not for fashion.

Design: Due to the lack of practical ways to 3D print fashions, there are fewer designers focused on the area and thus fewer fashions to 3D print.

Fit: Given the typically enormous cost of 3D printed fashions, there is no room for error. You can’t just print another size and try it, as you’d blow your budget.

While others are working on reducing the cost of 3D printing, it may be that Bodyblock has a solution for the last constraint: Fit.

Imagine an online system that, as apparel systems can, asks for simple body measurements. Using Bodyblock’s service a highly accurate 3D model can be instantly provided. This 3D model could then be used to resize and reshape a template 3D object so that it fits the wearer perfectly. Then it could be 3D printed and sent to the customer.

I think it’s only a matter of time before some innovative 3D print entrepreneur takes up Bodyblock’s service to create a custom fashion 3D print service.

Via Bodyblock

No one seems to offer collaborative 3D printing modes on dual extrusion devices. We explain why this is the case.