![The Prusa Bear Upgrade [Source: Thingiverse]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb097a798984.jpg)

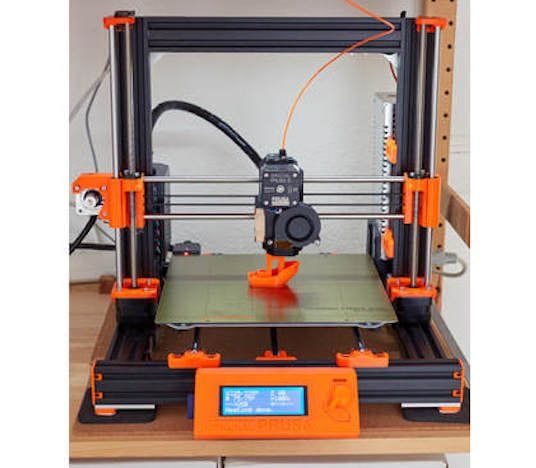

There’s an exciting upgrade for the most popular 3D printer around: the Prusa Bear Upgrade.

Prusa Research recently announced they have delivered over 100,000 desktop 3D printers, which is surely the most by any manufacturer. It’s a very popular machine, and the reasons for that are pretty straightforward: it’s an inexpensive machine that is highly reliable, with high-quality results, and has a great support network. That combination should make any manufacturer successful.

But among their numerous customers are those who are still not satisfied with the results, and they endeavor to create upgrades of various sorts to improve machine performance. Many of the Prusa community’s upgrades are simple in nature, but there’s one that is quite a bit more serious.

Switzerland-based Grégoire Saunier devised the Prusa Bear Upgrade, which is a comprehensive frame transplant for the popular device.

What problem is the Bear Upgrade addressing? It’s vibration. While the machine is printing it is possible for very slight vibrations to occur in frames of the Prusa i3 models. These vibrations eventually transition to the moving nozzle, resulting in very slight wiggles in the output.

The idea is to stiffen the frame to significantly reduce these vibrations and consequently increase print quality even more than it already is.

![Split view of a Prusa 3D printer before and after the Bear Upgrade [Source: Thingiverse]](https://fabbaloo.com/wp-content/uploads/2020/05/prusa-bear-upgrade-before-after_img_5eb097a7c4707.jpg)

That requires, well, some surgery on your Prusa device, because all of the components in the system attach to the existing frame. They must all be de-installed and re-attached to the new rigid frame.

The new frame is made from 2040 vslot extrusion aluminum. This is far more rigid than the standard Prusa frame components, which are essentially flat pieces. The extrusions involve corners that inherently make them far more rigid. What’s stronger, a piece of paper, or a piece of paper folded?

Saunier fortunately had some excellent objectives when designing the Bear Upgrade. He ensured the design is compatible with all recent Prusa models, from the MK2 all the way to the current MK3. That should include the vast majority of the 100,000+ Prusa devices in circulation.

The upgrade is available in two designs: a full upgrade and a half upgrade, which seems to involve fewer axes. The reason for having two options is to allow those with less budget to obtain some benefit.

![Comparing the full and half Bear Upgrade for Prusa 3D printers [Source: Thingiverse]](https://fabbaloo.com/wp-content/uploads/2020/05/prusa-bear-upgrade-half-full_img_5eb097a7ee138.jpg)

Extrusions are interesting in another way: they are far easier to mount additional modifications upon, as the extrusions used are standard in industry and thus compatible with many other projects.

Saunier has provided the designs in an open source fashion, with the goods being available publicly on GitHub for anyone to download and attempt. This includes the design files themselves in Fusion 360.

But for convenience, it is recommended you purchase an upgrade kit containing the necessary parts all ready to go. Saunier has organized a series of resellers to carry the kits, located in various regions worldwide. It should be easy to order them anywhere.

A couple of cautionary notes here: first, this is not an official Prusa upgrade, and thus you cannot expect assistance from them if you screw up your machine surgery. However, Saunier points out there are support services available from the public on Facebook, GitHub, Thingiverse and a Discord server.

Secondly, this is a relatively serious upgrade and thus it should be attempted by only those feeling very confident about their ability to literally deconstruct the machine and rebuild it.

Via Thingiverse

The fate of major 3D printing conferences in 2020 is unclear with the ongoing virus outbreak. We have thoughts on what it could mean.