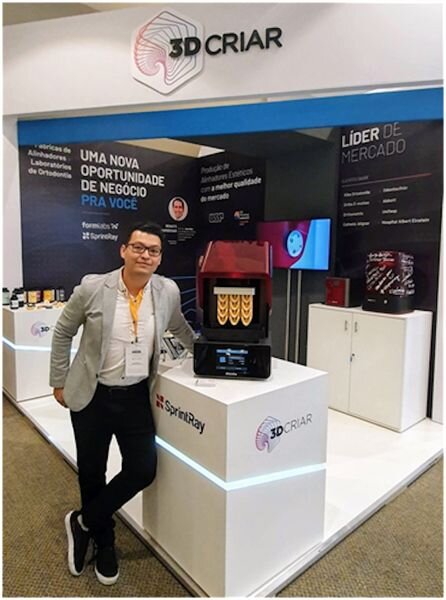

In a recent conversation with Daniel Huamani, Chief Technology Officer at 3D CRIAR, R&D Tax Savers got an interesting view of how additive manufacturing is fostering innovation in Brazil.

Having worked at Autodesk for over four years, Huamani has built upon his international project management experience to create a business model that helps customers find effective 3D printing solutions based on their specific needs.

Founded in 2015, 3D CRIAR is the largest 3D printing reseller in Brazil. It focuses on understanding each client’s challenges and determining the most advantageous use of additive manufacturing to overcome them – hard task considering the portfolio of five different technologies (FFF, SLA, DLP, SLS, and Color FFF) and over forty 3D printing materials. Equipped with a team of engineers, the company works closely with potential customers to identify the most effective combination of printers and materials to advance their goals. From multinational corporations to healthcare and educational institutions, 3D CRIAR has supported the integration of 3D printing capabilities across numerous industries in Brazil.

When asked about promising areas of application of additive manufacturing in emerging countries, Huamani argued that the revolutionary potential of 3D printing is not restricted to any particular industry. 3D CRIAR’s efforts, however, have targeted three main areas, namely, education, manufacturing, and healthcare.

Echoing an international trend, a growing number of Brazilian schools and universities are creating Fab Labs or makerspaces where students can use 3D printing as a learning tool and a resource for their own projects. Both public and private institutions are increasingly aware of how technology can contribute to greater student retention, development of soft skills, and implementation of creative teaching strategies. 3D CRIAR itself was created within an incubator at the University of São Paulo (USP), which remains an important partner. The Company sponsors research projects and works closely with various USP departments, including the School of Dentistry, the Institute of Technological Research, the Institute of Mathematics and Statistics, and the Polytechnic School.

3D CRIAR has also been involved in equipping public schools in the city of São Paulo with additive manufacturing technology. Huamani underlined the challenges involved in training teachers and giving them tools to make the most of newly implemented technology. Having worked with over 100 school teachers, 3D CRIAR believes that training and support are crucial for the long-term success of 3D printing initiatives within educational environments.

After multiple years of recession, Brazilian manufacturers are increasingly optimistic about the economic upturn. Huamani highlighted that the recent technological advancements in 3D printing, as well as new, high-performance materials, put 3D CRIAR in a great position to respond to this much-awaited economic expansion. The company works closely with the automotive industry, having clients throughout the entire supply chain.

Within the healthcare industry, 3D CRIAR has a particularly strong presence in odontological applications, including invisible aligners, prosthetics, etc. The company focuses on bridging the technical gap between manufacturers of 3D printers and dental professionals, allowing prospective clients to have an accurate view of different technological solutions in light of specific applications. Despite major international advancements in other health-related areas, such as implants and bioprinting, Brazil still faces significant regulatory and economic challenges.

3D CRIAR is highly active in trying to increase accessibility to additive manufacturing technology in Brazil. Unfortunately, the Company has faced common challenges often referred to as “Brazil cost” or the increased operational costs of doing business in the country. Aiming to overcome that, 3D CRIAR works closely with providers to facilitate financing options. Having recently hired a new CEO, Jorge Geras, the Company is ready to tackle new markets and expand its offerings in 2020.

Via 3D CRIAR (Portuguese)