Researchers at Harvard and the Wyss Institute have developed a new form of extrusion-based 3D printing they call “MM3D”.

The process is quite unusual, and yet familiar at the same time. It involves combining two new concepts together: multiple heads and fast material switching.

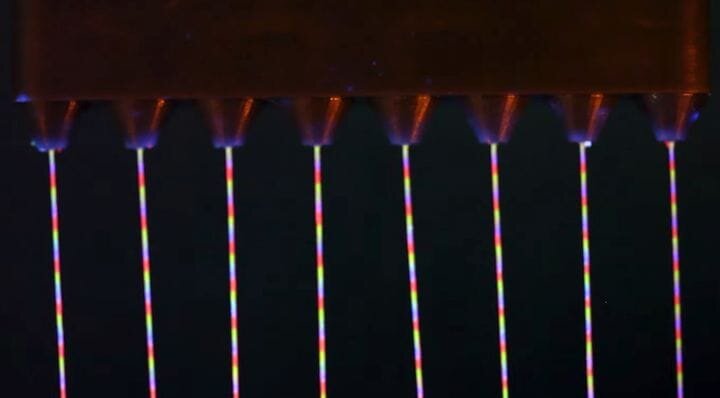

Of the two, the fast material switching is the most interesting. Structurally, it looks like this:

![Detail of a MM3D material switching nozzle with two channels reaching the tip [Source: YouTube]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08c92b95b5.jpg)

As you can see in the image, the nozzle is outwardly the same as any other 3D printer nozzle, but on the inside there are two channels leading to a point just before the exit point. In these channels lies soft, extrudable material.

Pressure-Controlled 3D Printing

By precisely controlling the pressure of material in each channel, the researchers were able to directly control the switching of material from one channel to another. You might expect there to be a “drip” from the wrong side, but this is avoided through extreme control of pressures.

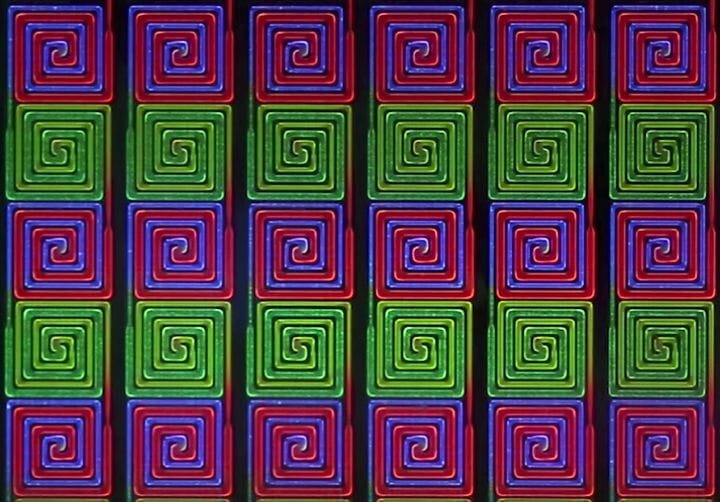

The pneumatic system allows the materials to be switched at a rate of up to 50X per SECOND! Thus when 3D printing at speed you can achieve a kind of voxel-level control over the material produced. There is likely a “quantum” size of voxel that can be produced with a MM3D system, and in theory an entire object could be produced with that voxel resolution.

Here is a video of the process at work:

The researchers developed MM3D nozzles that included up to eight separate material channels, making a type of “octonozzle” unseen in 3D printing circles.

![Eight MM3D 3D print nozzles rapidly switching materials [Source: YouTube]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08c9300ee4.jpg)

I should note that at the other end of the channels are essentially syringe-like devices that push the material and thus control the pressure.

MM3D Epoxy Prototype

One interesting side effect of the multiple MM3D nozzle is to 3D print epoxy materials, with the two root materials each supplied by a separate channel. By varying the ratio of the two, the researchers were able to 3D print an object with a gradient of hardness. That’s not easily done in any other 3D printing process I am aware of, aside from Stratasys’ PolyJet.

The other feature of the MM3D concept is the use of multiple nozzles. These seem to be arranged in a fixed array that moves all nozzles simultaneously. This means that each nozzle is literally 3D printing the same geometry all the time.

MM3D Limitations and Challenges

I don’t think the fixed array is a particularly good idea, as it removes a major factor in determining the strength of the resulting 3D printed object. Many 3D printer operators carefully consider the orientation of a print job to ensure that the extruded lines of material align with the expected stresses on the object.

However, that’s essentially impossible with the MM3D concept, as each large object would be necessarily 3D printed in adjacent “zones” corresponding to the reach of each nozzle. That introduces many, many seams that could be points of failure for the print.

Indeed, I didn’t mention that the syringe system obviously constrains the types of printable material in the system greatly. It’s unlikely objects of any strength can be produced with MM3D, unless there is some type of post processing step that further cures the print to a greater strength. Indeed, the examples shown in the video are flexible prints not requiring much part strength.

![A flexible 3D print made into a walking platform by MM3D technology [Source: YouTube]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08c9339d9e.jpg)

Nevertheless, this is a fascinating 3D printing concept that needs further exploration. It’s entirely possible that MM3D is very applicable to niche industries requiring certain types of flexible prints.

Via Nature