![A view of kupol's 3D printed helmet safety system [Source: kupol]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a95eb5ba1.jpg)

For a long while, it seemed that only a few industries truly made use of 3D printing.

Those would be: prototyping, certain medical prints, aerospace parts and a scant few others. But increasingly lately I am seeing “3D printing” sneak into designs for a variety of products that would otherwise have been made in traditional ways.

One interesting example is Quebec-based kupol, who have developed a new style of bicycling helmet. Their tagline is “Reinventing the helmet”, and they’re not kidding.

It’s fascinating how they’ve looked at a very commonly used item and realized how truly awful they are today when you imagine what could be made with a different form of technology.

Today’s bike helmets are almost universally made in the same way: hard plastic shell with some foamy stuff inside. Relatively easy to manufacture, but with some cool designs and safety engineering.

But what could be different when using 3D printing? kupol explains:

In the 20+ years since bike helmets first hit the road, not much has changed in terms of safety and design: inflexible hard plastic shells, polystyrene foam interiors that overheat, standard protection features.

That’s why kupol has come up with a revolutionary idea that turns every, single aspect of helmet design on its head—all thanks to 3D printing, the future of head protection. Think technology that responds to accidents that happen in real life, not just linear impacts. Materials and components designed to keep air moving, not trap heat in. A fit molded and sized for comfort, not a one-size-fits-all model.

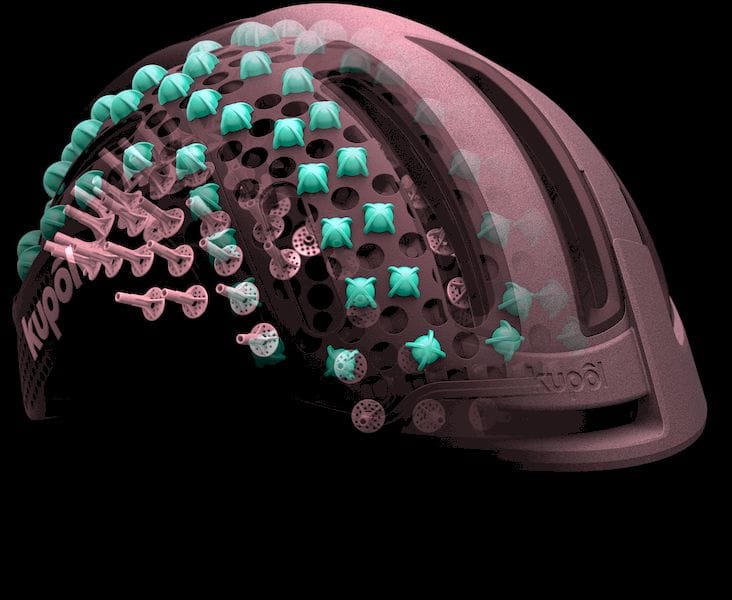

While standard bike helmets use a common foam as the shock absorbing material, kupol has designed a 3D printable mechanism they call the “Kollide Safety System” that leverages the complex designs made possible by 3D printing to create a more “active” system.

![kupol's 3D printed cycling helmet comfort system [Source: kupol]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a95f2da27.jpg)

Their design resolves several difficulties we didn’t know we had: the helmet is lighter in weight; is breathable and thus far cooler (and your head is a major source of body heat); handles impacts far more intelligently and from different directions. They explain how it works:

Most bike crashes involve side collisions, yet most helmets are designed for linear impact. It’s the reason the brains behind kupol came up with the helmet’s innovate patent-pending 3D technology, the KOLLIDE SAFETY SYSTEM, featuring three layers of revolutionary safety.

Our other KINETIC BUMPERS cushion your head in the event of a fall, helping to absorb the impact before it ever reaches you. Then our middle 3D KORE system is designed to collapse on impact in order to take the brunt of the force and keep you safe. Finally our inner OKTOPUS technology is comprised of over 100 sucker-like pods that line the inside of the helmet, making traditional polystyrene foam a thing of the past.

I like the complexity of the design and it seems to be a better solution for cyclists. But will it sell?

That’s the biggest question. Will consumers accept or be attracted to a “3D printed” solution? Do you even need to mention that it’s 3D printed? Yes, 3D printing is a kind of magic, but it’s shine with the public may have worn off.

Perhaps consumers will simply resonate with a new kind of “magic product”, rather than resonating with a “magic making process”. In the end any purchase should be evaluated on the performance and price of the product, not how it has been made.

I think we will see more of this type of application in the next few years. While kupol has transformed the bicycle helmet concept, there are countless other opportunities that new startup businesses may begin exploring.

Via kupol