3D printing is now becoming widespread, but full color 3D printing is still a rare thing.

To find out more about the state of full color 3D printing we spoke with Josh Hope, Sr. Manager, 3D Printing & Engineering Projects at Mimaki USA. Mimaki offers one of the most interesting full color 3D printing options available today. Their equipment produces highly lifelike reproductions with brilliant color.

Fabbaloo: Mimaki is a relatively new vendor on the 3D print scene from our perspective, and one of the very few to offer full color texture printing. It seems that there are fewer who require color 3D printing than conventional monocolor printing, but can you tell us who needs full color printing? What industries and applications are gaining value from it these days?

Josh Hope: Color 3D printing is definitely a small subset of additive manufacturing as a whole. In general, the main applications in manufacturing are in visual prototyping and appearance modeling.

Companies that have already embraced 3D printing in monocolor for prototyping but require hand coloring or painting of the 3D object are looking for ways to automate this process and reduce the number of touches in the workflow.

Color 3D printing allows for accurate repeatable results that often times either can’t be produced by manual processes or require too much time. Reduction of manual processes mean faster turnaround times, more repeatable results, lower overall costs and a faster time to market.

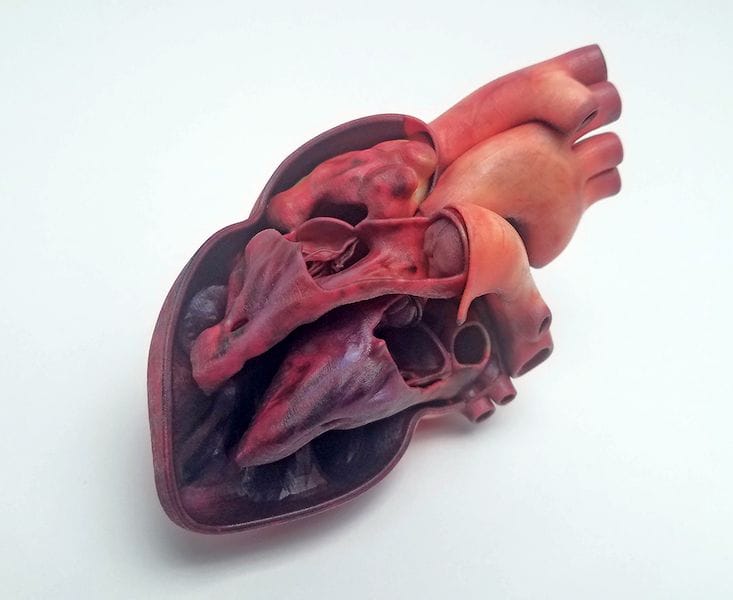

The medical market is another area that color 3D prints are making a big impact. The ability to accurately reproduce not only the shape but also the color of patient specific models is a market that continues to rapidly expand.

Fabbaloo: Can you explain and contrast the sophistication of color reproduction between the current 2D and 3D printing industries? I get the impression that the state of color in the world of 3D printing may not be where it should be.

Josh Hope: Accurate color reproduction in the 2D world has some major advantages, but many of them are already making their way to 3D printing.

Both 2D and 3D color output processes are typically done with CMYK devices so the RGB to LAB to CMYK color space conversion is very much the same. The main difference we see right now is that so many color 3D files were never intended to be output, they were only expected to be seen on a monitor or TV screen.

As color 3D output becomes more common we will see higher resolution texture files, and wider gamut color working spaces that better match a wide gamut CMYK output device. We are also seeing the introduction of software to allow for custom ICC output profiles such as the Mimaki Profile Master 3 software. This allows the end user to print a series of charts on their color 3D printer and then measure the output to create an ICC output profile specific to their output device and environment.

This is a great way to introduce process control into the workflow in a very similar way that would be done on a wide format 2D inkjet printer.

Fabbaloo: I’m always astonished at the detail and color vibrancy of Mimaki color 3D prints. What is the secret technology you use to produce these incredible colors?

Josh Hope: Mimaki has been working with highly accurate color reproduction in the wide format inkjet printing world for many years. Color accuracy is critical in the signage and textile markets where we are often producing output that has to match a Pantone specified corporate color within a very tight tolerance. The ‘secret’ is a tight integration of inks, software and hardware by our R&D team in Japan.

Fabbaloo: Do people ever mistake your color prints for “the real thing”?

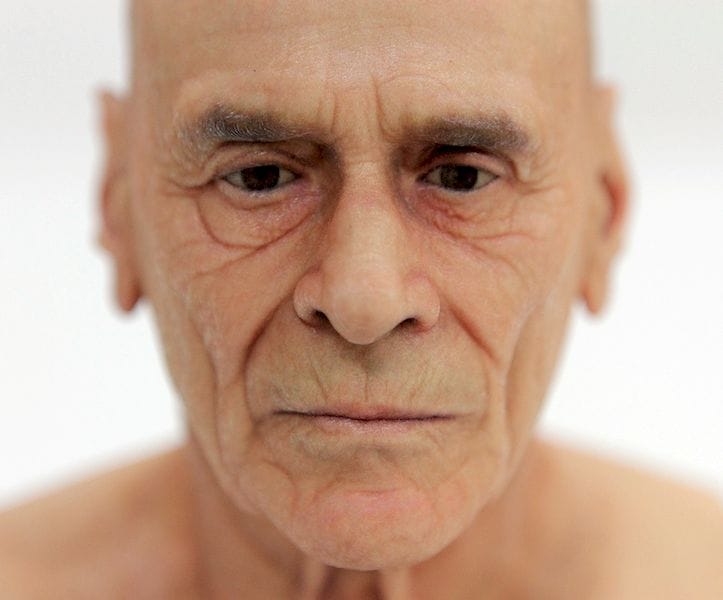

Josh Hope: One of the things that I like to point out is that when people take cell phone pictures of our human head prints at shows, the camera in the phone will highlight the print as a human face for focusing which I think is fantastic.

Fabbaloo: Is color 3D printing more expensive than conventional 3D printing? Why is that, and does it really matter?

Josh Hope: That is a hard question to answer due to the number of different 3D printing technologies in the market today, but I would say that color 3D printing is really not any more expensive than monocolor 3D prints from the same printing technology.

In our printer, the white and color resins are the same material with just different pigment in them depending on the color so the difference in cost is really minimal between monocolor or color.

Fabbaloo: What’s the best way for a company to get started in full color 3D printing? I assume it isn’t simply buying an expensive full color printer, so where is the starting point?

Josh Hope: There are more and service bureaus that are offering color 3D printing services and that is a great place to start. One thing to be aware of though, is that the term ‘full color 3D printer’ is now being used very loosely in the market. Any color 3D printer that has CMYK inks, pigments, or filament can be considered a ‘full color’ 3D printer, but it is the addressable number of possible output colors defines how accurate the final prints will be.

The range in the market now for ‘full color’ 3D printers seems to be ranging anywhere from about 48 colors up to over 10 million colors. Be sure to select an output device that gives you the level of color accuracy you need for your project.

Fabbaloo: Where do you believe color 3D printing is heading in the future? Are there unusual applications being discovered that few yet know about?

Josh Hope: As 3D color output becomes more accessible and the types of materials available to print with expands we will see it become the norm in additive manufacturing. Medical applications are one area that I am constantly amazed at the new and unique ways that color 3D printing is being used.

Fabbaloo: Will Mimaki be introducing new equipment? In particular, I’m interested to know if there will be a smaller, less expensive model.

Josh Hope: In Japan, Mimaki is primarily an engineering company and we pride ourselves on a constant cycle of product development. I can’t divulge what we currently have in the works, but keep an eye out for new Mimaki 3D innovations, you won’t be disappointed.

Via Mimaki