Car manufacturers are constantly exploring new technologies as a way to get ahead in the market.

We are now seeing customization of vehicles via 3D printing technologies. The latest example of this comes from MINI with their MINI Yours customized range of products.

Mini Customization

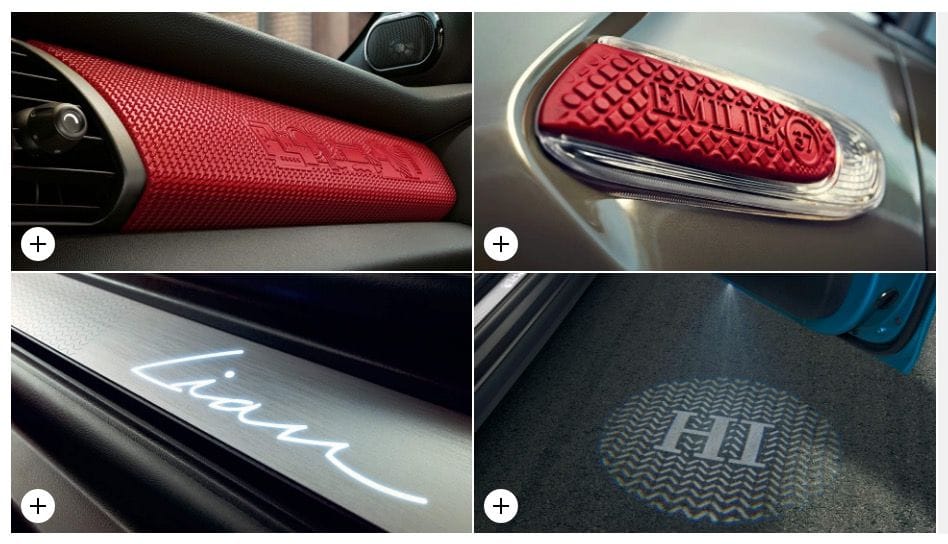

The two main products in the range that adopt 3D printing tech include the MINI cockpit facia and customizable side scuttles. The concept behind these is that you can produce your own designs, incorporating anything from your name or other details personal to your individual style. As BMW Group stated in their official announcement, “the 3D printing procedure has also been specially tailored to the production of highly individual products in large numbers”. Only available from earlier this year, the range has already seen success amongst MINI enthusiasts and within the industry.

In fact, MINI Yours customized was awarded the German Design Council’s German Innovation Award in Gold in the category Excellence in Business to Customer (B2C). This is testament to the innovative nature and flexibility of personalization they are offering their customers.

Pioneering 3D printing

MINI are demonstrating a clear commitment to the adoption of new automotive technologies within their manufacturing. The 3D printing process used to configure these items uses technology that has been developed via strategic partnership between BMW Group, Hewlett-Packard Inc., Carbon Inc. and EOD GmbH.

As to the manufacturing process, marketing materials suggest the application of the Continuous Liquid Interface Production (CLIP) method. This type of innovative 3D printing allows MINI to produce the customized items much quicker than otherwise possible.

By facilitating an oxygen-containing “dead-zone” between the solid and liquid precursor, solidification fails to occur. The liquid is then renewed by the upward movement of the solid part. This allows for the production of detailed products containing features with a resolution below 100 µm.

The printed parts are then cleaned and painted to match the customers’ requirements. Using the CLIP process has allowed for a major focus on ensuring that all customized items conform to the same form, functionality, safety standards and level of detail found in MINI’s standard accessories.

Given the technology and complexity of 3D printing the personalized car parts are surprisingly affordably priced. Both the side scuttles and cockpit facia are currently available to customize and purchase in Europe at a cost of €145 a piece.

We are excited to see the inclusion of 3D printing technology in the ongoing development of customizable cars. Although relatively small in their current application, the strategic partnership between BMW Group and technology leaders is a promising one. The possibilities are significant with much more substantial customization and functioning car part printing on a large scale a possibility for the future.