We had the opportunity to do a hands-on test with the new 3DWOX 1 3D printer from Sindoh, and there is a very special feature on this new model.

This is part 2 of a 2 part review. Part 1 is here.

If you’re read part one, you’ll no doubt agree that the 3DWOX 1 is an incredible desktop 3D printer. But there’s another feature that puts this machine over the top: open filament.

The one knock on the original 3DWOX DP200 series was that it used proprietary cartridges. While this provided a very high assurance of successful and high quality prints, it didn’t leave much choice in filament material types and colors.

Those with open filament machines know very well that there has been an explosion of choice in the materials market, with not only a wide choice of colors, but also a huge variety of new materials, some specifically designed for 3D printing. All of this choice was unavailable with the previous 3DWOX systems.

Now that’s changed entirely. While the new 3DWOX 1 does indeed still use the cartridge system, they now have a special “open filament” mode in which you can use virtually any 3D printer filament.

Entering “open filament” mode is as straightforward as flipping a setting on the control panel. At that point you are able to load standard, non-cartridge spools in the machine. While the cartridges are square-shaped, the round foreign spools are accommodated by a curved dip at the bottom of the materials chamber. There is no rotating system; spools just spin on this curved surface.

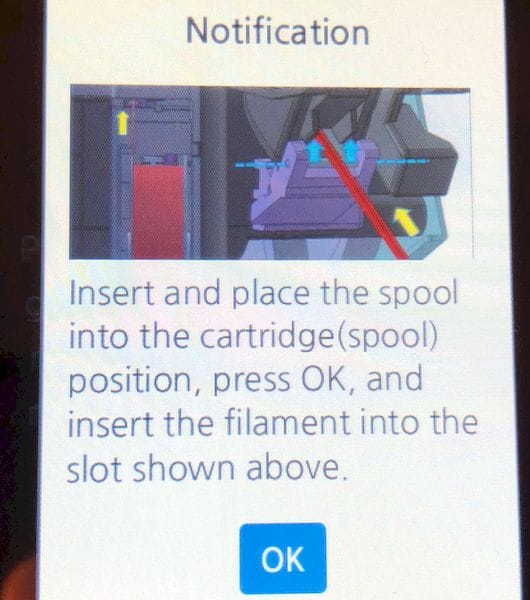

Loading filament is mostly straightforward. You simply place the spool in the chamber and feed the filament end into a specific spot where it will be grasped by the extruder motor.

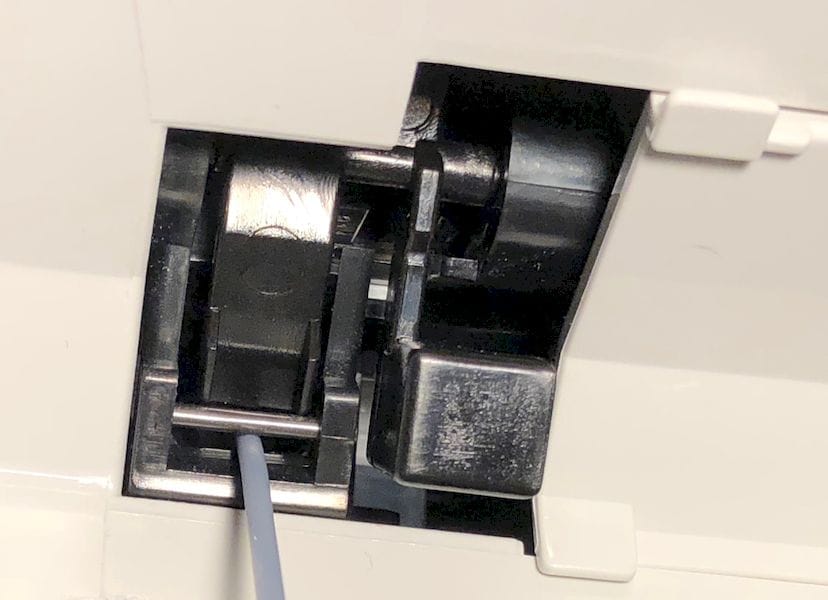

However, I did encounter a problem here. It turns out that there is a way to incorrectly insert the filament. This is the incorrect way:

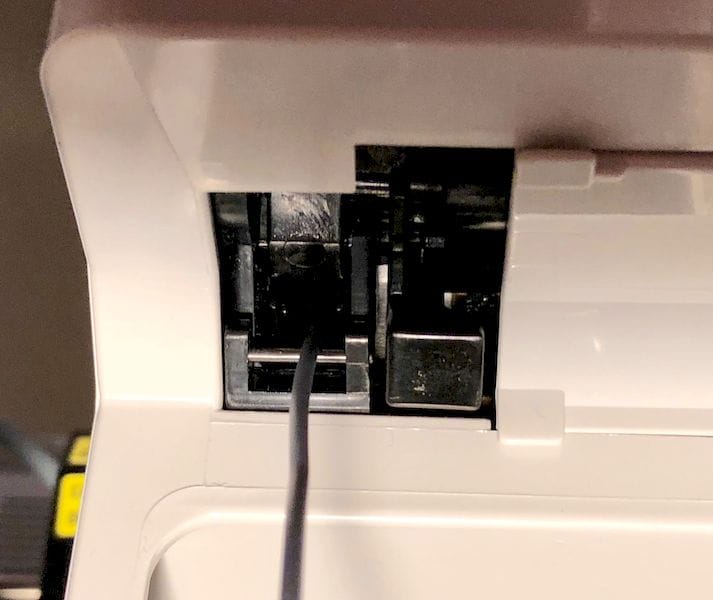

This is the correct way:

Somehow the machine did grab the filament when I loaded it incorrectly and even fed it right through the path to the hot end. However, because of the misalignment at the beginning, it kept getting confused because the filament would only occasionally be detected. Moral of the story: put the filament in the correct spot. It would be nice if Sindoh could devise a plastic shield or similar item to prevent this from happening.

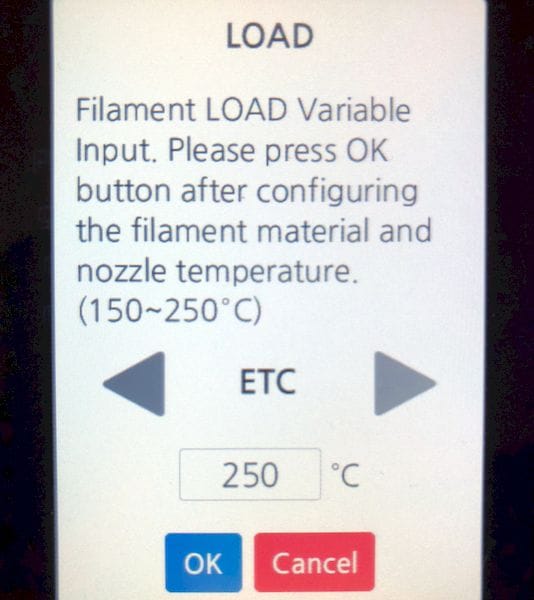

You’ll have to choose a temperature profile when loading open filament, because the machine has no idea what you’re putting in it. You have a choice of three temperatures: PLA (200C), ABS (230C) or ETC (250C). One of these will definitely work for your material.

Once your open filament is loaded, you are ready to print. However, you have to prepare a properly sliced 3D model first.

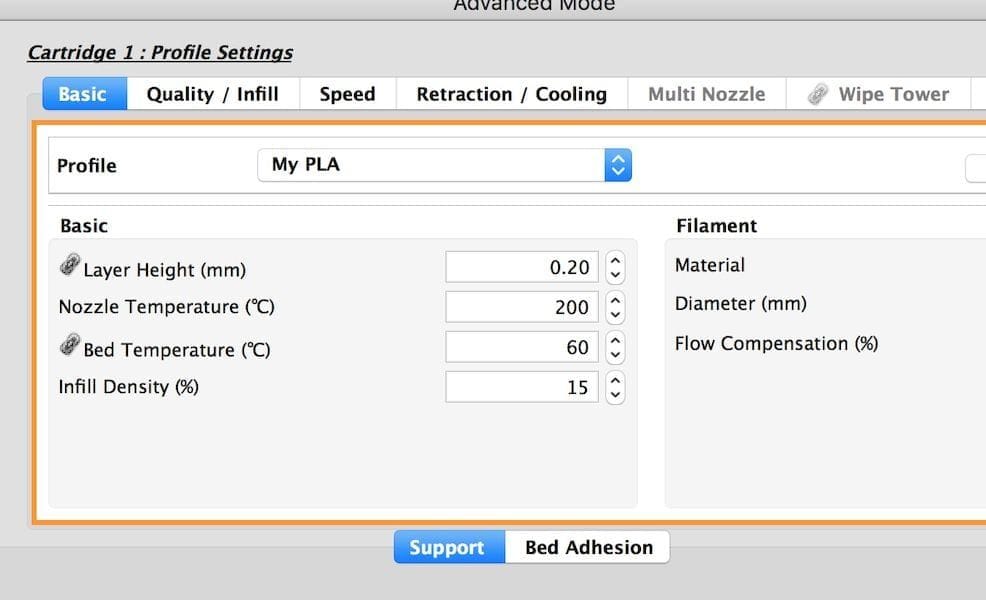

To do this you cannot use the normal 3DWOX settings, as they are expecting cartridges. Instead you must create a new material profile, which is easy to do. I made one for each of the materials I wished to test.

Sindoh makes creation of new profiles easy because you can base your new profile on one of their existing profiles. So, for example, if you wanted to use your own PLA material, you would create a new profile based on “Sindoh PLA”, and then tweak it as required.

#Profile

However, Sindoh provides only three such profile options: PLA, ABS and “ETC”, meaning “everything else”. So if you wanted to 3D print in PET, say, you’d create a profile based on “ETC” and then ensure all the parameters are correct. This shows the benefit of cartridges, as they have all this stuff set properly. However, Sindoh doesn’t offer PET cartridges, so that’s moot.

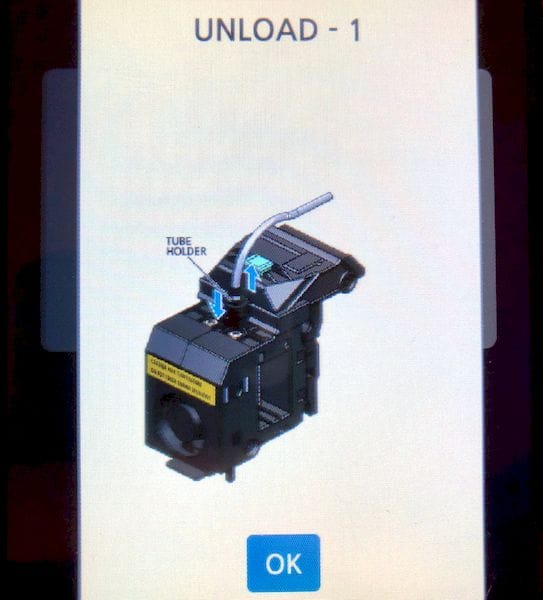

Unloading open filament is a bit different. Most machines simply ask you to press the unload button, and the machine heats up and pulls the filament back. The Sindoh open filament procedure requires you to pull off the PTFE tube from the extruder and snip the end of the filament off before proceeding.

#Cut

I suspect this is to ensure there isn’t a blob on the end of the filament that may get stuck in the tube, or perhaps interfere with the filament out detection system. I don’t see a problem if you don’t do this in most circumstances (and I tested this without incident), but it is a curious requirement.

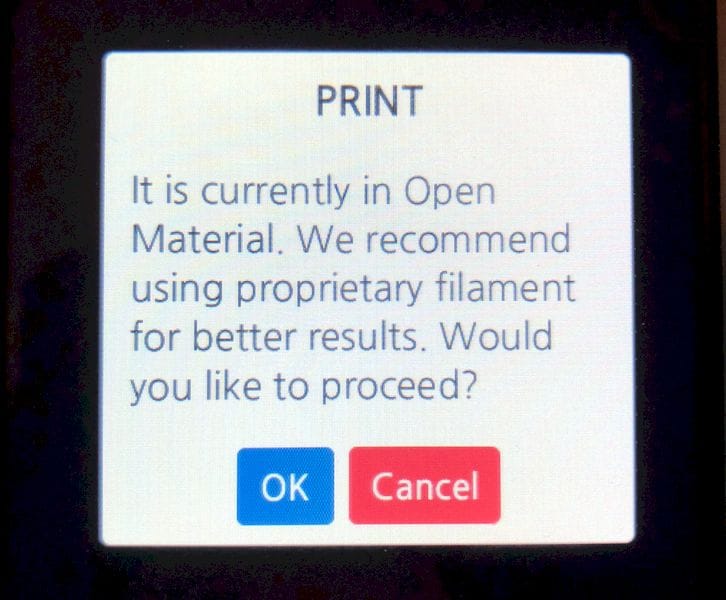

Back to printing. When you first attempt to 3D print a 3D model using open filament, you get this:

I suppose they want you to be sure of the difference between open and closed materials. However, if you got this far, I think you would know this already.

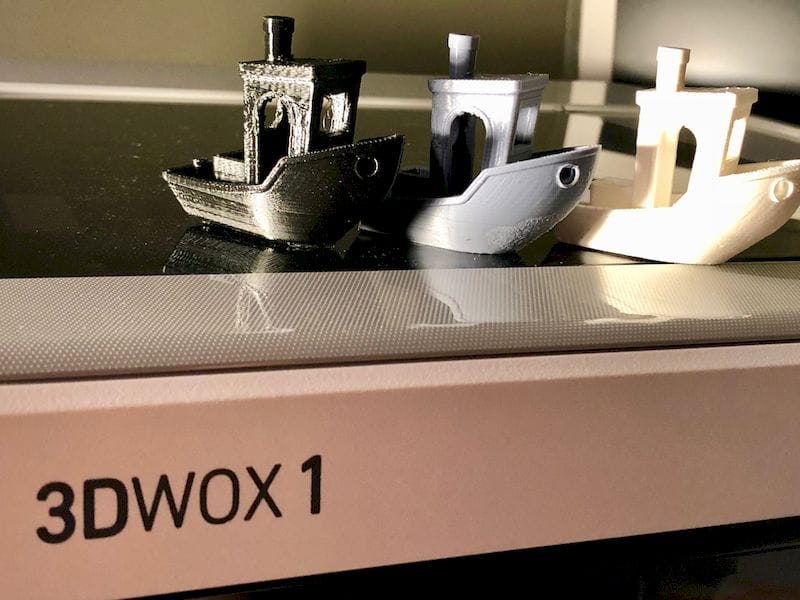

#Abs

I managed to 3D print objects on the 3DWOX 1 with PLA, ABS and even PET materials from sources other than Sindoh, so this feature definitely works, and works well. All objects printed came out quite well.

One slight issue was the PET I used stuck to the print bed very well, and I had to use the scraper a bit more than I expected. I also found the raft would stick to the PET object far tighter than the other materials. Probably I need to tune the gap between the raft and the object a bit, but that’s the beauty of open filament – you can do this!

The 3DWOX 1 is capable of open materials, but that doesn’t mean it can handle ANY materials. It cannot handle:

- High temperature materials like PEEK; the enclosure and other components are not hi-temp capable

- Flexible materials; the extruder system isn’t designed for this

- Highly abrasive materials, like metal filaments; the nozzle would erode

Regardless of these constraints, the open filaments opens up the 3DWOX 1 to a gigantic world of filament choice – and filament pricing, too.

After printing with the 3DWOX 1 for a while now, I can certainly recommend it as a very powerful machine, particularly because of the open filaments mode. It’s slightly more expensive than the previous model, at USD$1,499, but if you are looking for a high quality, easy to use machine, this could be it.

This is part 2 of a two-part series. Part 1 is here.