We got a pitch from Essentium about their mysterious upcoming 3D printer, the HSE.

Essentium first emerged a couple of years ago with a revolutionary materials idea: use electrically conductive material to use a resistive effect between the hot end nozzle and build plate to heat the material while it is printing. In this way the print can be far stronger as layer bonds can be significantly better.

They say the resulting prints can be as strong as standard injection molding parts, which do not have delamination issues like some 3D printed parts do.

The company obviously had to build their own machine in order to print this material, as typical 3D printers do not have this electrical heating feature. However, they’ve since licensed the technology to other 3D printer manufacturers and in fact you can buy a Stacker device integrated with Essentium’s FlashFuse technology.

Since then they’ve also announced a partnership with BASF (as have many other 3D printing companies), which should (and has) allowed them to greatly expand their portfolio of “fuse” style materials. They say they’ll have 20 “industrial grade filaments” available soon, including many already released.

But at our last meeting with the company, they touted something they call the “HSE”, a kind of super-printer, apparently.

This seems to be a production-style extrusion machine with a large build volume. I cannot say much more about the machine, because Essentium isn’t telling any details. In fact, this is all you will see from their website:

At 10x faster than the competition, Essentium’s High Speed Extrusion (HSE) platform is built to transform manufacturing floors and solve the issues of strength, speed, and cost. You can finally harness the power of 3D printing at scale without sacrificing accuracy or speed.

The HSE offers up to class leading print speeds, the strength of injection molded parts using Essentium FlashFuse™, and the ability to heat the nozzle from 20 C to 600 C in less than three seconds, making it the only platform to serve as a complete solution to unlock industrial applications of additive manufacturing.

Starting at $55,000 – Reserve your HSE for $500

Releasing Q4 2018

This sounds quite interesting, but being a skeptic, I’d like to see a bit more details about this machine, and hopefully we will get them before they release the printer to the public later this year.

There’s also this video:

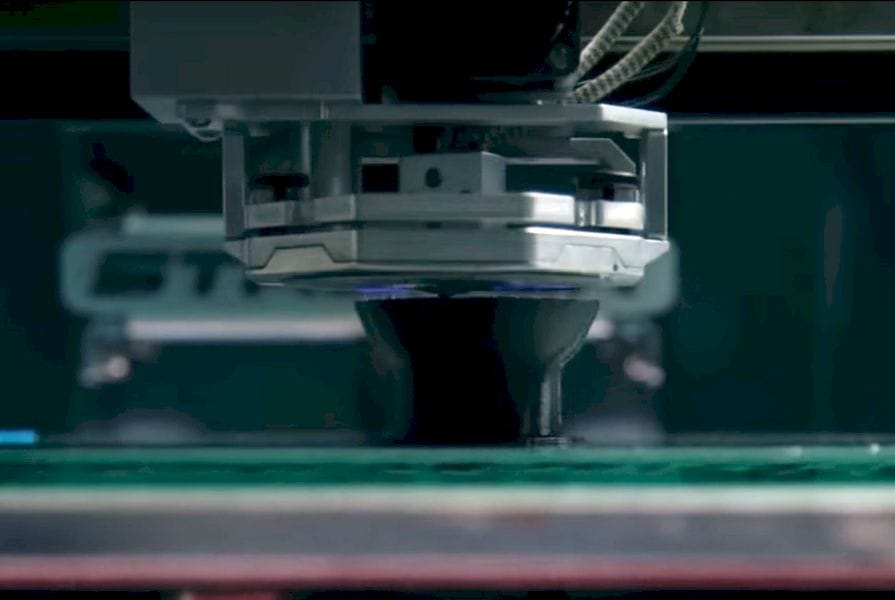

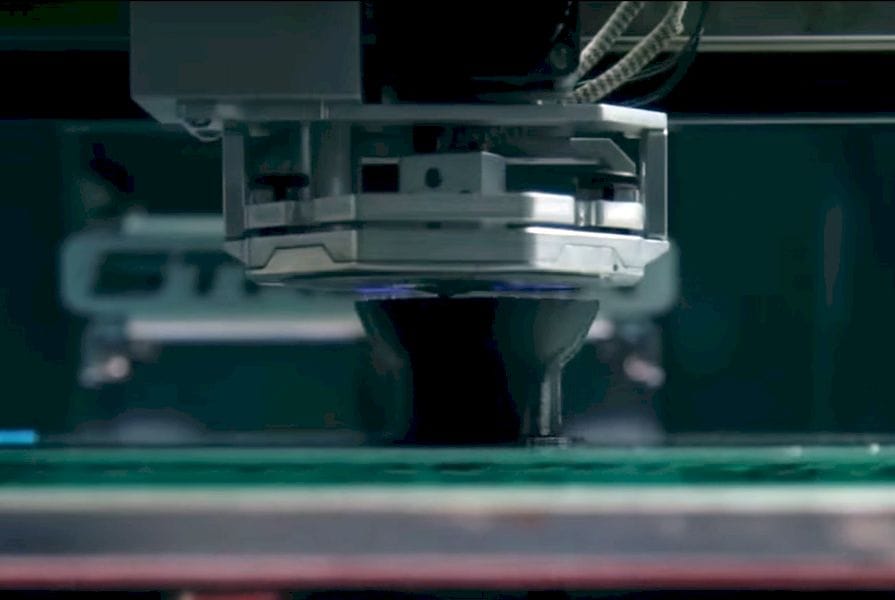

In the video there are some intriguing views, although seen only briefly and not explained at all.

First there is the build volume of this machine. It seems to be quite large, which would place it in competition with companies like BigRep, 3D Platform and others.

The machine, at least in this prototype form, does not appear to have an enclosure, meaning that heat could escape. This is definitely not good for many engineering materials, so I expect them to add some kind of heated enclosure before the machine is released.

Secondly there is the extruder. The key to rapid 3D printing using the extrusion process is always the extruder. Other companies seeking rapid build times, like 3D Platform, for example, have radically redesigned their extruders to have higher temperatures, super-fast flow rates, large filament sizes – or even pellets, and specialized materials. Is this what Essentium is doing?

It’s not clear, but certainly this is a rather different kind of extruder. They say that it can heat from 20C to 600C in only three seconds. That’s definitely fast, but wait, 600C? Who prints at 600C?

I think this might be a clue to their approach: by having extreme nozzle heat, a unit of thermoplastic need only be exposed to it for a short period of time to properly soften. Thus you could in theory run the flow a lot faster, and therefore decrease build times.

There’s also that curiously enormous motor mounted on the extruder. Why such a large motor? Perhaps it has something to do with a rapid flow rate, it may require higher torque. This is quite interesting because such a large motor will surely introduce a great deal of weight on the extruder itself, which must be pushed to a fro at high velocities in order to achieve the fast print speeds. The added weight will add some difficult to overcome momentum when the direction of extrusion suddenly changes.

This has been a limiting factor on the speeds of other machines, so I am curious to know how Essentium has solved this problem. To achieve 10X faster prints, you likely have to move the extruder 10X as fast, or more. That means this machine must have a very interesting motion system.

But we don’t know much about it, at least not yet. I’m looking forward to more details.

Via Essentium