Pricing of low-cost 3D printers has consistently dropped, but is this a good thing?

When I first got involved in desktop 3D printing many years ago, the pricing of equipment was quite different from today.

For USD$2,000 then you might have obtained an unassembled kit with a huge number of parts, with many hours and skills required to build it. And then you weren’t guaranteed results, as you often had to scrounge up the operational software as well as deriving the correct 3D printing parameters. In retrospect it wasn’t the best of experiences, but at least I learned something: most people would not want to go through that experience.

Today it’s quite different. For USD$2,000 you’ll be able to obtain any of several highly polished machines all entirely assembled and tested, with numerous convenience features like automatic calibration, networking and perfectly adhesive platforms.

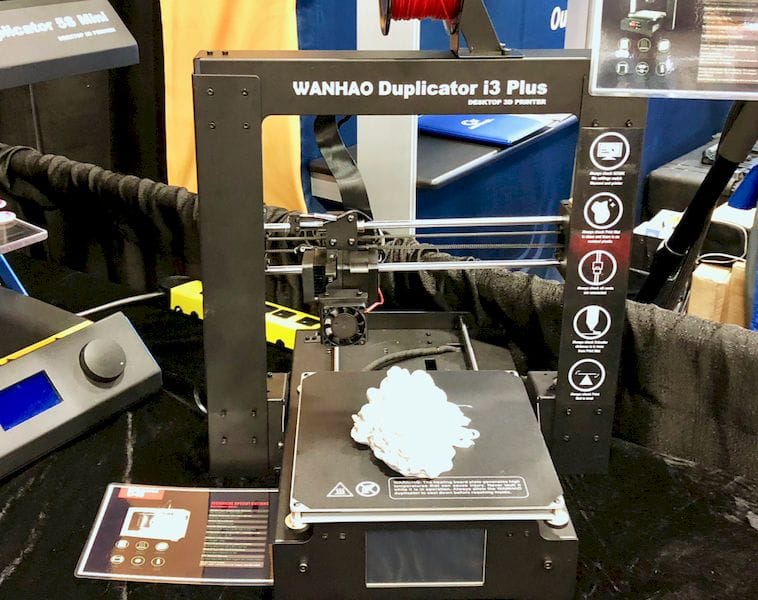

But for a lot less, say USD$500 and under, you can also get machines with somewhat lesser capabilities, but still far more functional than the original machines.

In fact, there are several dozen manufacturers pursuing this ultra-low cost market, mostly based in Asia to take advantage of inexpensive manufacturing.

Over the past few years we’ve seen these companies battle to drop the cost of 3D printing ever lower. At one time, in 2012, it was huge news when someone proposed a sub-USD$100 3D printer, when machines at the time typically cost around USD$1,000. However, that project did not work out well.

http://www.fabbaloo.com/blog/2016/10/24/a-not-so-peachy-update-on-the-peachy-printer

But that failure aside, Asian manufacturers continued to drive down the price, many eventually nearing that magic USD$100 price point. To be clear, these are the most basic machines you could imagine, and they’re certainly not appropriate for most people to use due to the lack of features – and in some cases, safety.

http://www.fabbaloo.com/blog/2018/3/22/3d-printer-safety-at-issue-again

But they put pressure on manufacturers of more capable equipment. The unknowing public may opt to purchase the lowest cost machine without realizing they might be better off with a more expensive unit that is more in line with their skills and abilities.

That pressure has caused a general lowering of 3D printing prices across all ranges. The sub-USD$500 market puts pressure on the USD$3,000 market, who ingeniously devise ways to lower their costs. But that in turn puts pressure on the more expensive machines, and all the way up the line to the most expensive manufacturers, who now look to creating production machines to gain new markets as they have trouble competing with all the low-price options at all levels.

Back to the question: are rock-bottom priced 3D printers good for the industry?

My answer is yes:

- It causes all companies to ensure their machines are of value

- It creates significant competition

- It causes more expensive machines to justify – and include – automation features to distinguish them from the lower priced models

- It causes lower prices on materials, even in the highest priced markets

So even if a USD$100 3D printer is not for you directly, their presence is a good thing for everyone.