3D printing technology isn’t for every application, but what is it good for?

How can you leverage design for best use with 3D printing? What features enabled by 3D printing technology provide potentially huge benefit? What could make a part “different” through 3D printing?

This is quite an important subject because in almost all cases, making “the same thing you always did” using 3D printing is almost always more expensive, and slower, too. To actually make proper use of 3D printing, your design must change in ways that can only be efficiently created using 3D printing. But what are those ways?

I think there are six major aspects that should be considered by all designers considering a design for 3D print.

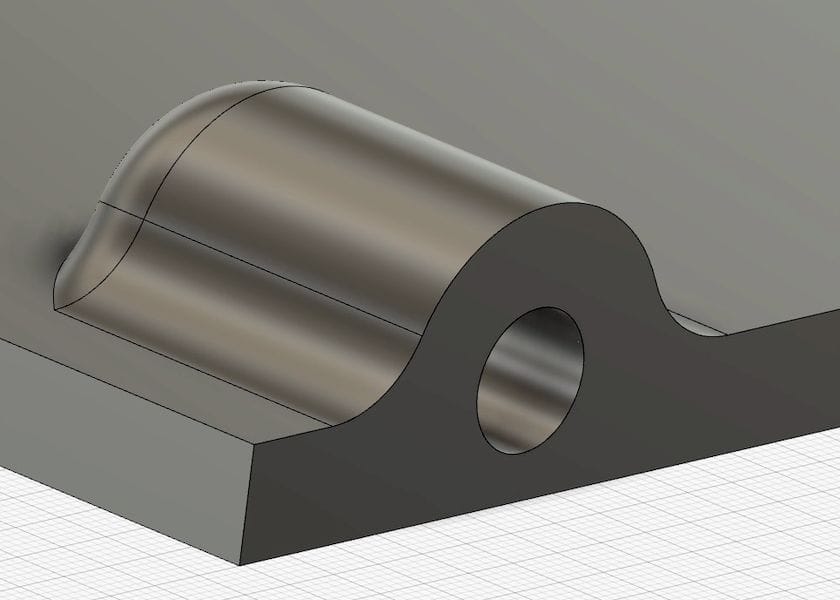

Fittings: These are elements that help parts stick together. They could be snap-fit joints, tongue-and-groove, or other common mechanisms. The idea here is that you build them directly into the part and don’t add them later as a separate part. The part is printed “ready” for connections.

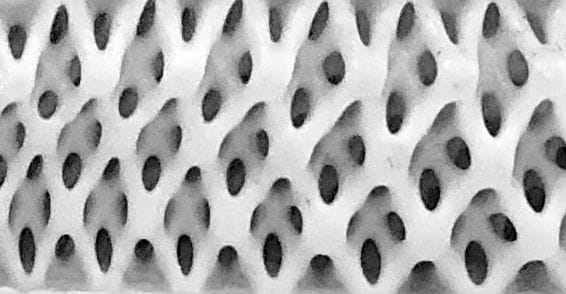

Lattice: This will perhaps be the method that drives the most use of 3D printing. Special generative software can dynamically create a highly complex lattice structure that in many cases can significantly reduce weight and materials yet still provide as much strength as required. And they look very cool, too.

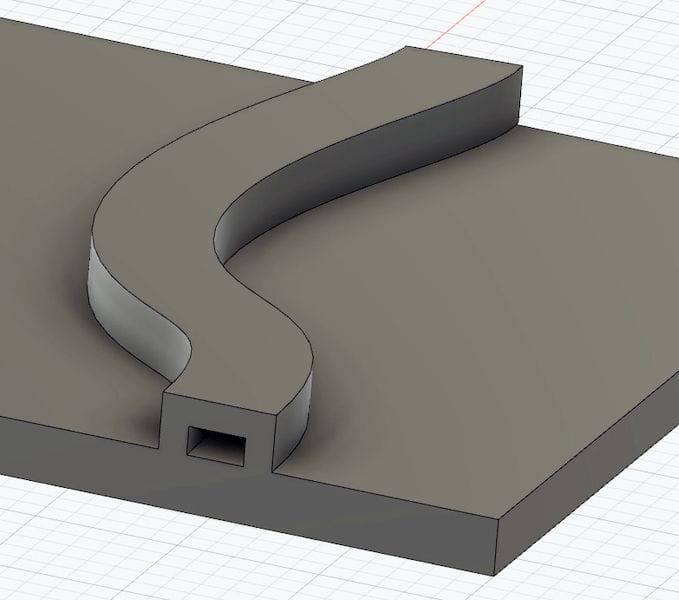

Channels: While we cannot currently efficiently 3D printing electrical circuits and wiring, we can design our parts to include the necessary channels and holes through which wiring can be inserted. This again reduces assembly because there is no need to attach such channels and drill holes in the part; they’re already there and ready for use.

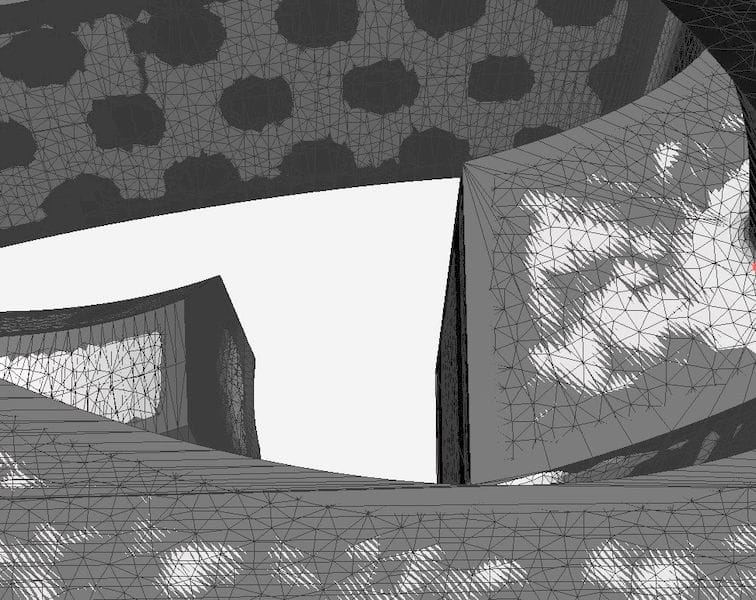

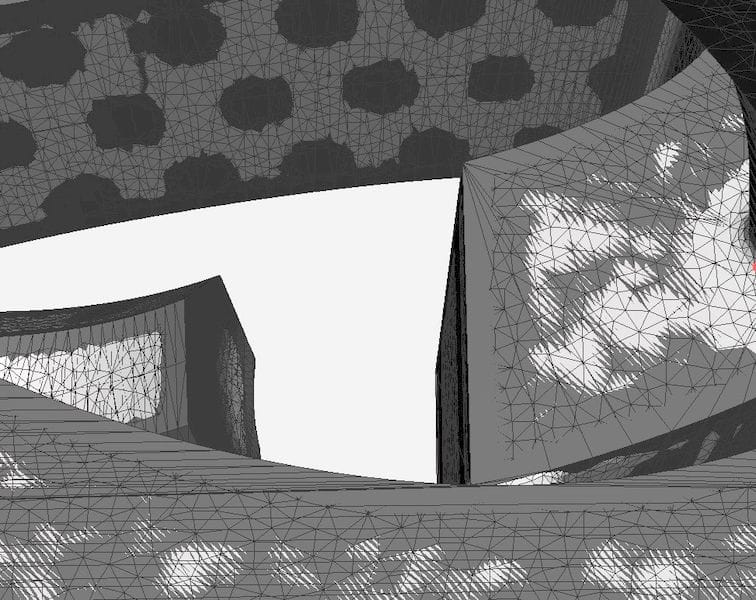

Complexity: Traditional making processes have a number of limitations, but the key constraint is often geometry; complex geometries are impossible to make using many techniques, but are easy to do with 3D printing. In practice this means complex components are traditionally made with many parts that must be assembled. But if you were to design for 3D printing the number of parts might be significantly reduced, perhaps even to only one. This saves considerable assembly time, part inventory and reduces risk of failure.

Customization: Traditional making processes often assume the goal is a series of identical parts. That approach occurs so often that we often think of manufacturing as for that goal only. Meanwhile the reality is that each individual actually needs parts that fit their particular situation. The benefit of 3D printing is that it can produce quantities of individually customized parts without any effect on costing or timing of production. Consider how parts can be made unique and more functional in each specific case.

Iteration: The cost of setting up a traditional manufacturing line can be considerable, but is usually paid for through the production of large quantities of parts. 3D printing doesn’t work that way, as the cost of each part is pretty much the same for any unit. This means that there is an opportunity to explore the design in ways not accessible using traditional making strategies. Consider using an iterative approach on any design to gradually – and efficiently – zoom in on the correct final design.

There are certainly many other ways to leverage 3D printing, and more will emerge in the future as machine capabilities develop. I imagine adding things like “material gradients” to this list in the future, for example.

But for now, these are the major approaches for truly leveraging 3D printing technologies.