Continuous 3D printing is a dream for many, but now it seems to be a purchasable thing.

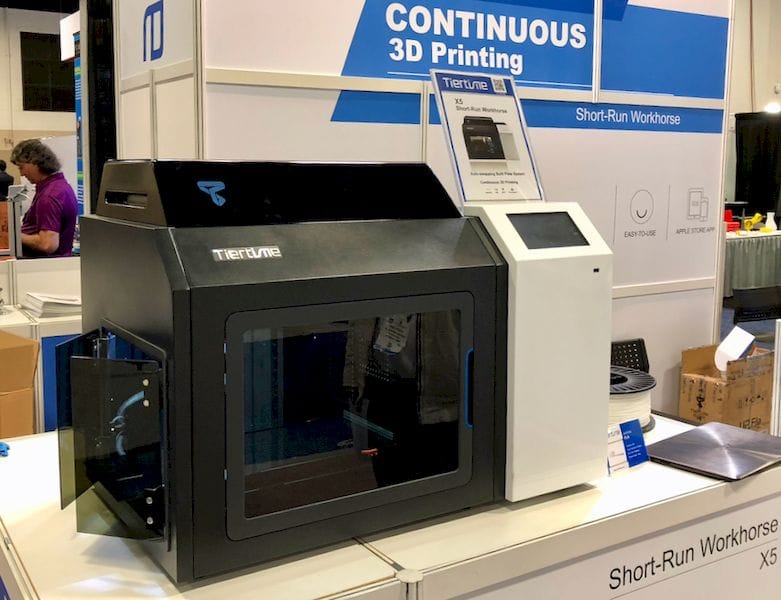

Longtime 3D print manufacturer Tiertime has developed a new system for continuous 3D printing and it’s different from other continuous systems we’ve seen.

Continuous 3D printing is an incredibly desirable feature because it frees the operator from the periodic activity of clearing the print bed of completed prints. With sufficient material, a continuous 3D print is essentially a small manufacturing device that can pump out dozens or even hundreds of parts completely unattended.

Many continuous 3D printing concepts involve some type of conveyor belt system, where the prints peel off the belt when they reach the end of the circuit. One system we examined recently involved a series of pins that pushed the print off the bed.

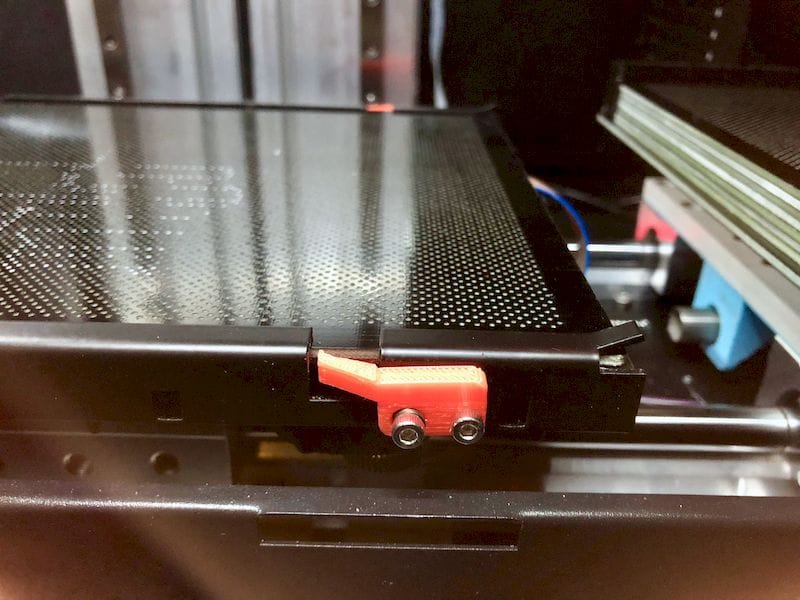

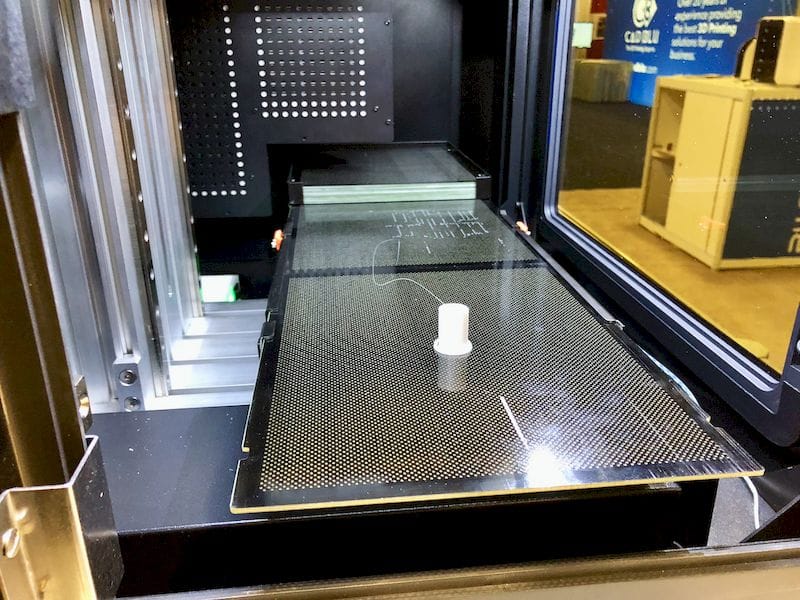

However, the new Tiertime X5 does not use either approach. Instead it makes use of separate, reusable print plates. A supply of plates is loaded into the machine prior to starting print jobs.

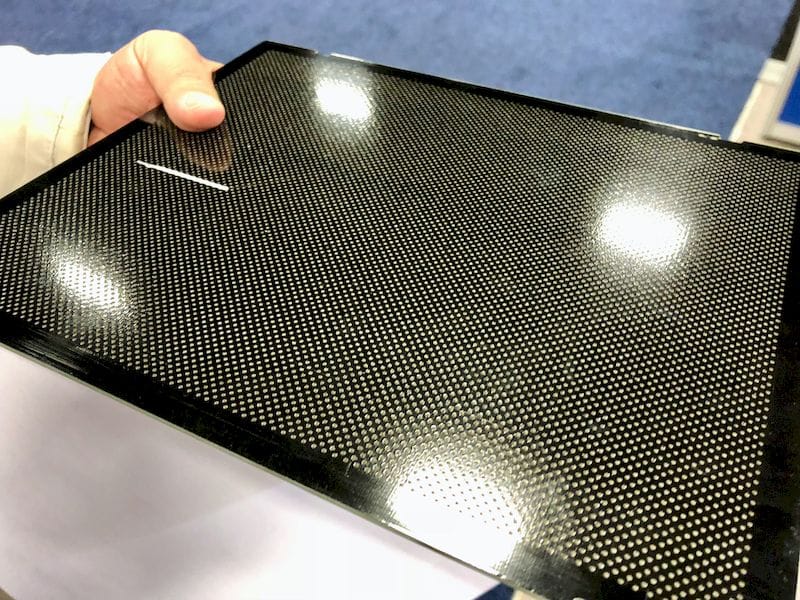

These preforated, very stiff – and flat – boards are a proven approach for print adhesion. They’re literally no different from ones you might use on some other 3D printers.

The mechanism slides a fresh board into place, and it’s pushed upwards into a pre-leveled bracket to ensure the plate is oriented perfectly. Then printing begins.

When the print completes, the board is driven out the side of the machine where it can be caught in a basket. Prints are not removed from the boards in this system, and must be manually peeled off the plate. But then the plate can be reloaded for subsequent prints.

One limitation of this approach is that you can print as long as you have a supply of plates, and it appeared to me that the X5 has a capacity. However, that capacity is likely far more than the material capacity, so you will probably end up changing the spool before you run out of plates.

The X5 includes a dual filtration system, HEPA and Activated Carbon, 299C extruder, 180 x 230 x 200mm build volume, and a build plate that can hit 100C.

The X5 is not quite available yet, but is to be fully released later this year. It should be interesting to see how well it sells, as this could be the only widely available continuous 3D printer available for purchase.

There’s one more thing: Tiertime had to make an interesting software change to accompany the continuous 3D printing approach: the machine also includes onboard job queuing!

This is much like you’d see in a 2D paper printer: make several job requests and they all magically queue up in the device. This doesn’t make sense for most 3D printers, as they are essentially single-job machines, where the operator must intervene after each job. But in a machine that can print continuously, it is a requirement.

Even better, Tiertime has decided to make this queueing feature available in ALL their 3D printers! Well, except the lowest level, where it really wouldn’t make sense.

The company has also replaced their popular desktop flagship printer with the new Up Mini 2 ES, which sports a fancy case, color touch screen, HEPA filter and of course the queueing system.

This would make the Up Mini 2 ES system ideal for educators, who would benefit not only from the sealed case and air filtration, but the ability for students to queue print jobs as well.

At only USD$699, the Up Mini 2 ES looks like a terrific option.

Via Tiertime (Up Mini 2 ES) and Tiertime (X5)